مجموعة FAW الروسية ذات العمود الواحد: إتقان 8 المكونات المهمة لنقل الطاقة بشكل لا تشوبه شائبة

ال مجموعة FAW الروسية ذات العمود الواحد, المعروف أيضًا باسم مجموعة عمود الإدخال, acts as the primary torque gateway for the CA3250P66K24L1TE5Z dump truck. Situated between the clutch friction disc and the main gear set, this high-precision assembly must endure violent torsional shock loads and extreme thermal cycling. This guide analyzes the engineering behind these 8 المكونات الاستراتيجية, defining the reliability of the مجموعة FAW الروسية ذات العمود الواحد in Arctic conditions.

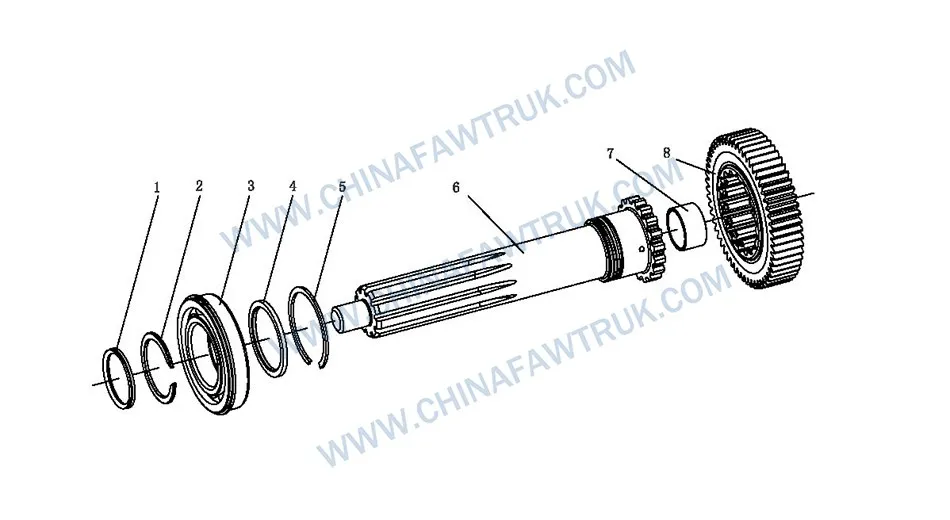

مجموعة FAW الروسية ذات العمود الواحد

الأساسية المعدنية: The Input Shaft and Gear

The structural spine of the مجموعة FAW الروسية ذات العمود الواحد هو First Shaft – الانتقال (الجزء لا. 1701112-A1K). This component functions as the direct interface with the engine’s power output. Unlike intermediate shafts that operate within the cushioned environment of the gearbox oil bath, the input shaft is exposed to the harsh, dry environment of the bell housing on one end and the gearbox internals on the other. It features precision-machined splines that mate with the clutch driven disc. في سياق مجموعة FAW الروسية ذات العمود الواحد, these splines must be surface-hardened to resist the fretting wear caused by the constant micro-movements of the clutch disc during engagement and disengagement.

Mated to this shaft is the Input Gear – First Shaft (الجزء لا. 1701121-A0L). This gear transfers the rotational energy to the countershaft, effectively initiating the gear reduction process. الهندسة وراء مجموعة FAW الروسية ذات العمود الواحد gears focuses on contact patch optimization. The gear teeth are ground to a helical profile that maximizes surface contact area while minimizing noise. في القطب الشمالي الروسي, where cold gear oil (often 80W-90) can be thick and viscous, the shear strength of these gear teeth is tested to the limit. The steel alloy used in the مجموعة FAW الروسية ذات العمود الواحد is heat-treated to a specific Rockwell hardness that balances surface wear resistance with core ductility, preventing tooth fracture under shock loads.

The interaction between the shaft and the gear is facilitated by the جلبة (الجزء لا. 1701111-A7G). This bushing acts as a sacrificial wear interface, protecting the expensive shaft and gear from galling. في مجموعة FAW الروسية ذات العمود الواحد, the bushing is designed with oil grooves that promote hydrodynamic lubrication. Even when the transmission fluid is sluggish due to extreme cold (-40درجة مئوية), these grooves channel oil to critical friction zones, التأكد من أن مجموعة FAW الروسية ذات العمود الواحد rotates smoothly from the first turn of the crankshaft.

تحمل المنطق: Managing Radial and Axial Loads

Supporting the high-speed rotation of the input shaft is the Deep Groove Ball Bearing with Stop Ring (الجزء لا. 6212-زنبر/C3YB2). This is not a standard industrial bearing; ال “ج3” designation in the part number indicates a specific internal radial clearance. في مجموعة FAW الروسية ذات العمود الواحد, this increased clearance is vital. As the transmission heats up during heavy hauling, the steel shaft expands. A standard clearance bearing would seize under this thermal expansion. The C3 bearing allows for this growth without binding, ensuring consistent operation across a temperature delta of over 100°C.

ال “زنبر” designation likely refers to the seal type or cage material, optimized for oil resistance and high temperatures. The integrated stop ring (snap ring groove) on the outer race allows the bearing to be axially located within the transmission housing. وهذا يمنع مجموعة FAW الروسية ذات العمود الواحد من “المشي” forward or backward under thrust loads. Thrust loads occur whenever helical gears mesh; they try to push the shafts apart axially. The deep groove geometry of the bearing raceways in the مجموعة FAW الروسية ذات العمود الواحد is specifically designed to absorb these thrust vectors while simultaneously handling the radial load of the gear mesh.

Protecting this bearing from the outside elements is the غسالة – First Shaft Rear Bearing (الجزء لا. 1701123-A7G). This washer serves as a spacer and a shield, ensuring proper preload and preventing debris from entering the bearing race from the gear side. طول عمر ال مجموعة FAW الروسية ذات العمود الواحد is directly tied to the health of this main bearing. If it fails, the input shaft loses concentricity, مما يؤدي إلى فشل الختم, clutch destruction, and eventual transmission seizure.

ختم النزاهة: The First Shaft Oil Seal

The boundary between the wet environment of the gearbox and the dry environment of the clutch housing is defined by the ختم النفط – First Shaft (الجزء لا. 1701135-A7G). In the engineering hierarchy of the مجموعة FAW الروسية ذات العمود الواحد, this is a critical failure point that must be fortified. A leak here allows transmission fluid to contaminate the dry friction disc of the clutch. Once oil touches the clutch disc, friction is lost, the clutch slips, and the truck becomes immobilized.

للسوق الروسية, the material composition of this seal is paramount. Standard Nitrile (NBR) seals can harden and crack at temperatures below -30°C. ال مجموعة FAW الروسية ذات العمود الواحد utilizes a seal manufactured from Fluoroelastomer (FKM/Viton) or a specialized low-temperature Acrylate (ACM). These materials maintain their flexibility and sealing lip memory even in the deep freeze. This ensures that when the shaft begins to spin on a cold morning, the seal lip maintains positive contact, preventing oil bypass.

The design of the seal lip often includes hydrodynamic pumping aids—small directional ribs molded into the rubber. As the shaft rotates, these ribs actively pump any oil film back into the transmission, creating a dynamic barrier. الانتهاء من السطح First Shaft where the seal rides is ground to a mirror polish to minimize friction and wear on the seal lip. This synergy between the shaft surface and the seal material is a hallmark of the مجموعة FAW الروسية ذات العمود الواحد, ensuring leak-free performance for hundreds of thousands of kilometers.

Selective Assembly: Snap Rings and End Play

The assembly of the مجموعة FAW الروسية ذات العمود الواحد ليس أ “one size fits all” process. It relies on a method known as selective assembly, particularly regarding the retaining rings. The BOM lists multiple part numbers for the حلقة المفاجئة – First Shaft Rear Bearing (جزء رقم. 1701131-A7G, 1701132-A7G, 1701133-A7G, 1701134-A7G). These represent snap rings of varying thicknesses, graduated in minute increments (على سبيل المثال, 0.05mm steps).

During the manufacturing or rebuilding process, technicians measure the accumulated tolerances of the housing, the bearing, and the shaft. They then select the specific snap ring that eliminates axial “نهاية اللعب” while avoiding excessive preload. في مجموعة FAW الروسية ذات العمود الواحد, controlling end play is vital. Excessive play allows the shaft to shuttle back and forth, causing gear misalignment and “التشويش” during load changes. Excessive tightness causes bearing overheating.

This precise tolerance stack-up ensures that the مجموعة FAW الروسية ذات العمود الواحد operates silently and efficiently. إدراج حلقة المفاجئة – عكس العتاد (الجزء لا. 1701314-A7G) further illustrates the complexity of the assembly, securing adjacent gear sets to maintain the overall integrity of the transmission cluster. This attention to detail in tolerance management differentiates the genuine مجموعة FAW الروسية ذات العمود الواحد from inferior aftermarket copies, which often use a single standard ring size leading to premature failure.

انهيار المكون: 103. One-Shaft Component Logic Assembly

| لا. |

رقم الجزء |

جزء اسم |

الكمية |

| 1 |

1701135-A7G |

ختم النفط – First Shaft |

1 |

| 2 |

1701131-A7G |

حلقة المفاجئة – First Shaft Rear Bearing (Selective Fit) |

1 |

|

1701132-A7G |

حلقة المفاجئة – First Shaft Rear Bearing (Selective Fit) |

1 |

|

1701133-A7G |

حلقة المفاجئة – First Shaft Rear Bearing (Selective Fit) |

1 |

|

1701134-A7G |

حلقة المفاجئة – First Shaft Rear Bearing (Selective Fit) |

1 |

| 3 |

6212-زنبر/C3YB2 |

Deep Groove Ball Bearing with Stop Ring |

1 |

| 4 |

1701123-A7G |

غسالة – First Shaft Rear Bearing |

1 |

| 5 |

1701314-A7G |

حلقة المفاجئة – عكس العتاد |

1 |

| 6 |

1701112-A1K |

First Shaft – الانتقال |

1 |

| 7 |

1701111-A7G |

جلبة |

1 |

| 8 |

1701121-A0L |

Input Gear – First Shaft |

1 |

خاتمة: The Gateway to Power

ال مجموعة FAW الروسية ذات العمود الواحد is the unsung hero of the drivetrain. It endures the highest RPMs and the most violent torque spikes of any transmission component. Its design reflects a deep understanding of the challenges posed by Arctic environments, from the low-temperature metallurgy of the shaft to the specialized polymer of the oil seal.

لصيانة الأسطول, the replacement of the مجموعة FAW الروسية ذات العمود الواحد is a precision task. It requires not just the correct shaft and gear, but the exact selective fit snap rings to ensure factory-spec tolerances. By adhering to this level of detail and using only genuine components, operators ensure that the power of the CA3250P66K24L1TE5Z engine is transferred to the wheels with 100% كفاءة, keeping the fleet moving through the toughest conditions on earth.

التعبئة والتغليف والخدمات اللوجستية

أجزاء فاو, بما في ذلك مجموعة كتلة الأسطوانة, يتم تعبئتها بعناية لضمان الولادة الآمنة. يتم تأمين كل مكون في مواد واقية لمنع الضرر أثناء النقل. تضمن الشبكة اللوجستية الشحنات في الوقت المناسب في جميع أنحاء العالم, دعم عمليات الصيانة الفعالة. فيما يلي صورة توضح العبوة القياسية لقطع غيار شاحنات FAW, إظهار الاهتمام بالتفاصيل في التعامل والتخزين.

يقلل أسلوب التغليف هذا من مخاطر التآكل أو التلف الناتج عن الصدمات, ضمان وصول أجزاء مثل FAW Cylinder Block Assembly في حالة ممتازة. يمكن للعملاء الاعتماد على الخدمات اللوجستية التي تقدمها FAW للحصول على الجودة والموثوقية المتسقة.