FAW Russian Air Conditioning Equipment: Mastering 16 Strategic Components for Ultimate Arctic Climate Control

The FAW Russian Air Conditioning Equipment serves as the atmospheric command center for the FAW CA3250P66K24L1TE5Z dump truck. In the frozen expanse of the Russian North, maintaining a habitable cabin temperature is not a luxury but a physiological necessity for operator survival. This system integrates heating, ventilation, and filtration into a robust unit designed to withstand extreme thermal cycling. By expertly managing airflow and air quality, the FAW Russian Air Conditioning Equipment ensures operator alertness and safety during grueling shifts in temperatures that can plummet to -50°C.

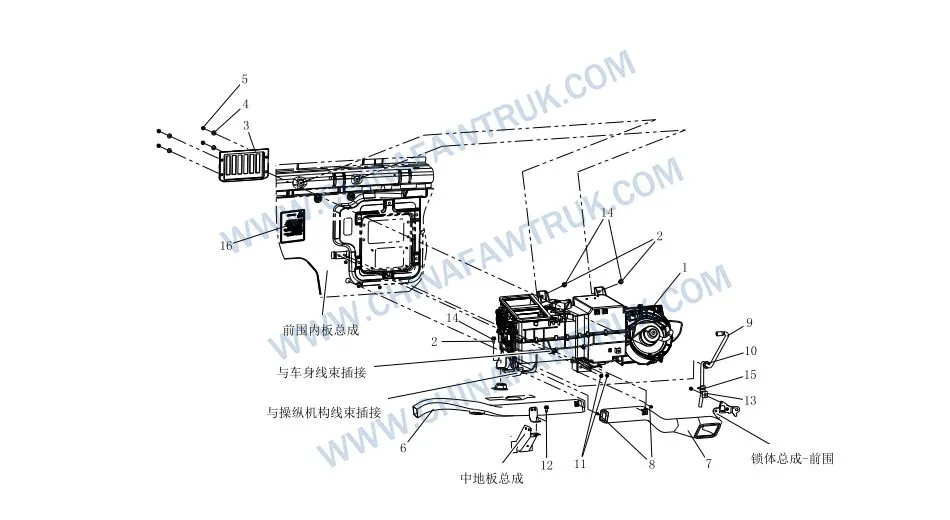

FAW Russian Air Conditioning Equipment

| No. |

Part Number |

Part Name |

Qty |

| 1 |

8100015-B27-C00 |

Two-box Assembly – Automatic Air Conditioning |

1 |

| 2 |

CQ1500620 |

Hexagon Head Bolt |

3 |

| 3 |

8101570-B27 |

External Air Filter Assembly |

1 |

| 4 |

Q40108 |

Washer |

4 |

| 5 |

CQ34008 |

Hexagon Nut |

4 |

| 6 |

8101160-A01 |

Driver Foot Air Duct Assembly |

1 |

| 7 |

8101185-B27-C00 |

Passenger Foot Air Duct Assembly |

1 |

| 8 |

CQ2714813 |

Cross Recessed Pan Head Tapping Screw |

2 |

| 9 |

8107066-A01 |

Drain Hose |

1 |

| 10 |

8107047-A01 |

Drain Hose Sheath |

1 |

| 11 |

CQ39606 |

Hexagon Flange Nut |

2 |

| 12 |

CQ1460820 |

Combination Bolt |

1 |

| 13 |

8100106-A01 |

Drain Hose Fixing Bracket |

1 |

| 14 |

Q40206 |

Large Washer |

3 |

| 15 |

T67414646 |

Plastic Band |

1 |

| 16 |

8100201AB89 |

AC Maintenance Warning Label |

1 |

Thermal Core: The Automatic HVAC Assembly

At the heart of the FAW Russian Air Conditioning Equipment lies the Two-box Assembly – Automatic Air Conditioning (Part No. 8100015-B27-C00). This complex module is the central processing unit for the vehicle’s climate control. In the context of the CA3250 dump truck, this assembly is engineered to deliver high-capacity heating to combat the pervasive chill of the Arctic winter, while also providing rapid cooling during the intense, short summers. The “Two-box” designation implies a separation of the intake/filtration unit from the distribution/exchange unit, a design that maximizes thermal efficiency and simplifies maintenance access within the crowded dashboard architecture.

The Two-box Assembly – Automatic Air Conditioning features an intelligent control module that automatically regulates fan speed and blend door positions based on cabin temperature sensors. This automation is crucial for the FAW Russian Air Conditioning Equipment system, as it allows the driver to focus on the hazardous terrain rather than constantly adjusting knobs. The internal heat exchangers are constructed from corrosion-resistant aluminum alloys, specifically chosen to withstand the internal pressure of the refrigerant and the external attack of condensation, ensuring that the FAW Russian Air Conditioning Equipment remains leak-free for years.

Furthermore, the FAW Russian Air Conditioning Equipment is designed with thermal shock resistance in mind. The transition from a cold start at -40°C to full operating temperature induces significant stress on plastic housings and seals. The materials used in the Two-box Assembly – Automatic Air Conditioning are formulated to maintain dimensional stability across this wide temperature range. This prevents the development of air leaks or “ghost” drafts that could compromise the cabin’s thermal seal, ensuring that the warm air generated by the system is delivered effectively to the driver without loss.

Filtration Strategy: Protecting Air Quality

The first line of defense for the FAW Russian Air Conditioning Equipment is the External Air Filter Assembly (Part No. 8101570-B27). In mining operations, the air is thick with abrasive silica dust and coal particulates. If allowed to enter the HVAC unit, these contaminants would quickly clog the evaporator core, freezing the system and causing catastrophic failure. The External Air Filter Assembly utilizes a high-capacity pleated media that traps fine particulate matter while maintaining high airflow rates. This filtration is essential not only for the health of the AC system but for the respiratory health of the operator.

The housing of the External Air Filter Assembly is designed to be weather-resistant, preventing snow and water ingestion. In the FAW Russian Air Conditioning Equipment system, a wet filter is a frozen filter, which blocks all fresh air intake. The intake geometry creates a tortuous path that separates heavier snow and water droplets from the air stream before they reach the filter media. This passive separation technology ensures that the FAW Russian Air Conditioning Equipment continues to breathe even during a blizzard, maintaining positive cabin pressure to keep dust out.

Maintenance of the External Air Filter Assembly is facilitated by accessible mounting points. Regular replacement of the filter element is a mandatory protocol for the FAW Russian Air Conditioning Equipment. A clogged filter places immense strain on the blower motor, leading to premature burnout. By ensuring that only clean air enters the Two-box Assembly – Automatic Air Conditioning, fleet managers protect the expensive core components of the system, reducing long-term repair costs and ensuring that the driver always breathes clean, conditioned air.

Precision Air Distribution: Ducting Logic

Effective climate control requires precise distribution, a task handled by the Driver Foot Air Duct Assembly (Part No. 8101160-A01) and the Passenger Foot Air Duct Assembly (Part No. 8101185-B27-C00). In extreme cold, maintaining blood flow to the extremities is critical for safe vehicle operation. Cold feet lead to delayed reaction times on the pedals. The Driver Foot Air Duct Assembly is sculpted to direct a high-velocity stream of warm air directly into the pedal box area, creating a “warm air curtain” around the driver’s boots.

The material construction of the Passenger Foot Air Duct Assembly and its driver-side counterpart involves high-impact polypropylene. This material is chosen for the FAW Russian Air Conditioning Equipment because it acts as a thermal insulator, preventing the warm air from losing its heat energy to the cold dashboard structure before it reaches the outlet. Additionally, the smooth internal surface of the ducts minimizes air turbulence and noise, contributing to the acoustic comfort of the cabin provided by the FAW Russian Air Conditioning Equipment.

Securing these ducts requires specific fasteners like the Cross Recessed Pan Head Tapping Screw (Part No. CQ2714813). The vibration of a mining truck can easily shake loose press-fit connections. The use of tapping screws ensures a positive mechanical lock into the HVAC housing. A disconnected Driver Foot Air Duct Assembly would result in a loss of heating efficiency and potentially allow cold drafts to bypass the heater core. The integrity of the FAW Russian Air Conditioning Equipment relies on these secure connections to deliver comfort where it matters most.

Condensation Management: Drainage Systems

An often-overlooked aspect of AC design is water management, handled in this system by the Drain Hose (Part No. 8107066-A01) and the Drain Hose Sheath (Part No. 8107047-A01). As the air conditioning removes humidity from the cabin air, condensate forms on the evaporator coil. In the FAW Russian Air Conditioning Equipment, this water must be evacuated immediately. If the Drain Hose freezes, water backs up into the unit, potentially leaking onto the electrical harness or refreezing into a block of ice that destroys the evaporator.

The Drain Hose Sheath is a critical component for the Russian specification. It provides thermal insulation to the hose as it passes through the cold floor of the cab. Without this sheath, the trickle of water inside the hose would freeze instantly upon contact with the sub-zero chassis, creating a plug. The FAW Russian Air Conditioning Equipment uses this sheath to maintain the water in a liquid state until it is ejected from the vehicle. This detail prevents the common failure mode of “frozen drains” that plagues lesser vehicles in Arctic conditions.

The physical routing of the hose is secured by the Drain Hose Fixing Bracket (Part No. 8100106-A01) and the Plastic Band (Part No. T67414646). These components ensure that the hose maintains a continuous downward slope, preventing water pooling. Any dip in the hose acts as a trap where water can collect and freeze. The FAW Russian Air Conditioning Equipment engineering ensures gravity-assisted drainage is uninterrupted, protecting the system from water damage and ensuring continuous dehumidification capability.

Conclusion: Essential Climate Survival

The FAW Russian Air Conditioning Equipment is a life-support system for the CA3250 operator. By integrating the high-capacity Two-box Assembly – Automatic Air Conditioning with the robust filtration of the External Air Filter Assembly and the freeze-proof drainage of the Drain Hose Sheath, FAW delivers a comprehensive solution for the Arctic. The system is held together by precision hardware like the Hexagon Flange Nut (Part No. CQ39606) and Combination Bolt (Part No. CQ1460820), ensuring it survives the brutal vibration of the mining pit.

For fleet maintenance, respecting the complexity of the FAW Russian Air Conditioning Equipment is vital. Ignoring the AC Maintenance Warning Label (Part No. 8100201AB89) or using generic parts can compromise the system’s thermal balance. By utilizing authentic components, from the Large Washer (Part No. Q40206) to the primary HVAC unit, operators guarantee that their fleet provides a safe, warm, and alert environment for their drivers, maximizing productivity in the world’s most challenging climate.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.