FAW Russian Rear Fender Assembly: Fortifying 14 Strategic Components for Ultimate Arctic Debris Control

The FAW Russian Rear Fender Assembly is a critical containment system engineered for the FAW CA3250P66K24L1TE5Z dump truck. Operating in the harsh environment of the Russian mining sector, this assembly serves as the primary barrier against heavy rock ejecta, corrosive road salts, and blinding snow spray. By integrating high-impact polymers with rigorous spray suppression technology, the FAW Russian Rear Fender Assembly protects the chassis integrity and ensures compliance with road safety standards in temperatures plummeting to -50°C.

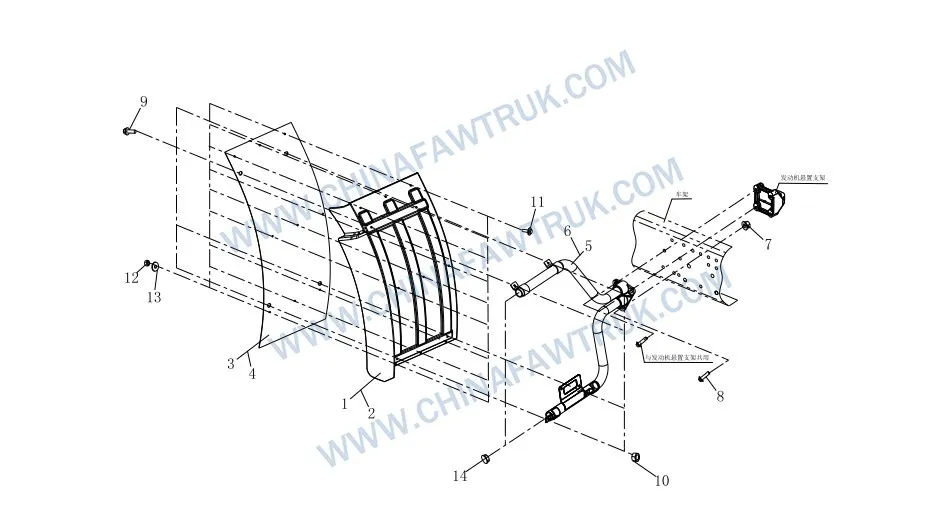

FAW Russian Rear Fender Assembly

| No. |

Part Number |

Part Name |

Qty |

| 1 |

5103361-72C |

Left Rear Fender |

1 |

| 2 |

5103362-72C |

Right Rear Fender |

1 |

| 3 |

5103383-55R |

Left Rear Fender Anti-Splash Guard |

1 |

| 4 |

5103384-55R |

Right Rear Fender Anti-Splash Guard |

1 |

| 5 |

5103365-55R |

Left Rear Fender Support Tube Assembly |

1 |

| 6 |

5103370-55R |

Right Rear Fender Support Tube Assembly |

1 |

| 7 |

CQ32614 |

Hexagon Flange Lock Nut |

2 |

| 8 |

Q1841455 |

Hexagon Flange Bolt (Coarse Shank) |

2 |

| 9 |

CQ1460825B |

Combination Bolt |

7 |

| 10 |

CQ34008 |

Hexagon Nut |

7 |

| 11 |

CQ1460620F6B |

Combination Bolt |

17 |

| 12 |

CQ34006 |

Hexagon Nut |

17 |

| 13 |

Q40206 |

Large Washer |

17 |

| 14 |

5103363-50A |

Pipe Plug |

4 |

Impact Resistance and Material Composition

The core defense mechanism of the FAW Russian Rear Fender Assembly is provided by the primary shield components: the Left Rear Fender (Part No. 5103361-72C) and the Right Rear Fender (Part No. 5103362-72C). These fenders are not merely aesthetic covers; they are structural armor designed for the “72C” cold-weather specification. The material used is a high-density polyethylene (HDPE) or similar thermoplastic, specifically modified to maintain impact ductility at extremely low temperatures. In the Arctic, standard plastics shatter like glass when struck by rocks, but the FAW Russian Rear Fender Assembly absorbs the kinetic energy of mining debris without fracturing.

The geometric design of the Left Rear Fender includes reinforced ribbing on the underside. This structural enhancement prevents the fender from sagging under the weight of accumulated heavy wet snow or ice, a common issue in Siberian operations. By maintaining its shape, the fender ensures consistent tire clearance, preventing rubbing that could damage both the tire and the fender itself. The surface finish of the FAW Russian Rear Fender Assembly is also treated to be hydrophobic, reducing the adhesion of mud and ice, thereby minimizing the parasitic weight added to the vehicle during operation.

Furthermore, the Right Rear Fender acts as a critical shield for the chassis components located behind the wheels, such as air tanks and hydraulic lines. By intercepting high-velocity stones and corrosive slurry, the FAW Russian Rear Fender Assembly significantly extends the service life of these sensitive systems. The chemical resistance of the fender material ensures that it is impervious to diesel spills, hydraulic fluid leaks, and the aggressive magnesium chloride road salts used for de-icing, maintaining its protective integrity throughout the lifespan of the dump truck.

Spray Suppression Technology

Integrated into the lower edge of the fenders are the Left Rear Fender Anti-Splash Guard (Part No. 5103383-55R) and the Right Rear Fender Anti-Splash Guard (Part No. 5103384-55R). These components are vital for active safety on wet haul roads. Unlike simple rubber mudflaps, these guards feature a complex surface texture—often a “grass” or matrix pattern—designed to absorb the energy of water spray rather than deflecting it back into the air. This technology drastically reduces the atomized mist cloud generated by the rear wheels, improving visibility for following traffic and the driver’s own rear-view mirrors via the FAW Russian Rear Fender Assembly.

The “55R” designation likely points to a specific rubber compound formulated for flexibility in sub-zero conditions. A standard rubber flap would freeze solid at -40°C, becoming a rigid board that could snap off when the truck reverses over a berm. The material used in the FAW Russian Rear Fender Assembly anti-splash guards retains its pliability, allowing it to yield to obstacles and return to its original shape. This flexibility is also crucial for shedding ice buildup; as the flap moves, it naturally cracks and dislodges frozen deposits.

Secure attachment of the Right Rear Fender Anti-Splash Guard is ensured through a series of robust fasteners. A loose guard is a significant hazard; if it detaches, it exposes following vehicles to rock projectiles. The FAW Russian Rear Fender Assembly design ensures that the interface between the rigid fender and the flexible guard is reinforced, distributing the wind load and preventing tear-out at the mounting holes. This attention to detail ensures that the spray suppression system remains effective even at highway speeds.

Structural Skeleton: Support Tube Assemblies

The rigidity of the entire system relies on the Left Rear Fender Support Tube Assembly (Part No. 5103365-55R) and the Right Rear Fender Support Tube Assembly (Part No. 5103370-55R). These steel tubes form the skeleton of the FAW Russian Rear Fender Assembly, cantilevering from the chassis frame to hold the fenders in position. They must be strong enough to withstand the intense vibration of the dump truck chassis without cracking from metal fatigue. The tubular design offers an excellent strength-to-weight ratio, resisting torsion and bending forces applied by wind and heavy mud accumulation.

To prevent internal corrosion, the ends of these support tubes are sealed with the Pipe Plug (Part No. 5103363-50A). These plugs prevent water, salt, and mud from entering the hollow tubes, where they would otherwise cause rust to rot the structure from the inside out. This seemingly minor component is critical for the long-term structural integrity of the FAW Russian Rear Fender Assembly. The plugs are made from a weather-resistant polymer that creates a tight interference fit, ensuring they remain in place despite chassis vibration.

The mounting interface of the Left Rear Fender Support Tube Assembly connects to the chassis using heavy-duty hardware like the Hexagon Flange Bolt (Coarse Shank) (Part No. Q1841455). The coarse shank design provides superior grip and resistance to stripping, which is essential for heavy structural connections. The tubes are typically powder-coated or galvanized to match the “55R” specification, providing an external barrier against the corrosive environment. This ensures that the skeleton of the FAW Russian Rear Fender Assembly remains as durable as the chassis itself.

Fastening Logic: Precision Hardware

The assembly of the FAW Russian Rear Fender Assembly involves a high quantity of specialized fasteners, specifically the Combination Bolt (Part No. CQ1460620F6B) and (Part No. CQ1460825B). The term “Combination Bolt” indicates that these fasteners come pre-assembled with captive washers. This is a crucial feature for maintenance efficiency and reliability. It ensures that the necessary load-spreading washers are never forgotten during assembly, preventing the bolt heads from pulling through the plastic fender material. The FAW Russian Rear Fender Assembly relies on this consistent clamping force to prevent rattling.

The “F6B” suffix on the bolts typically denotes a high-grade anti-corrosion coating, such as a zinc-flake dispersion or Dacromet finish. In the saline slush of Russian roads, standard zinc plating would fail rapidly, leading to seized fasteners. The specialized coating ensures that the Combination Bolt threads remain clean, allowing for easy disassembly when fender replacement is necessary. This focus on serviceability is a key aspect of the FAW Russian Rear Fender Assembly engineering philosophy.

Complementing the bolts are the Hexagon Flange Lock Nut (Part No. CQ32614) and standard Hexagon Nut (Part No. CQ34006). The flange lock nuts are used in high-stress areas where vibration is most severe, featuring serrated faces that bite into the metal surface to resist backing off. For the polymer-to-metal connections, the Large Washer (Part No. Q40206) is employed in large quantities (17 units). These washers distribute the compressive load over a wide area of the Left Rear Fender, preventing stress cracks around the mounting holes and ensuring the FAW Russian Rear Fender Assembly remains securely attached.

Conclusion: Robust Protection for Arctic Fleets

The FAW Russian Rear Fender Assembly is a comprehensive protection system designed to withstand the brutal realities of Arctic mining logistics. By combining the impact-resistant properties of the Left Rear Fender with the active safety features of the Left Rear Fender Anti-Splash Guard, FAW delivers a solution that protects both the vehicle and the surrounding traffic. The structural rigidity provided by the Left Rear Fender Support Tube Assembly ensures that this protection is durable and long-lasting.

For fleet operators, the maintenance of the FAW Russian Rear Fender Assembly is essential for regulatory compliance and vehicle preservation. Replacing a missing Pipe Plug or a damaged Combination Bolt prevents the onset of corrosion and structural failure. By utilizing genuine FAW parts that meet the specific cold-weather specifications, maintenance teams can ensure that their dump trucks remain operational, safe, and clean, regardless of the challenging conditions encountered on the Russian haul roads.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.