FAW Russian Lower Mirror: Mastering 6 Strategic Optical Components for Critical Blind Spot Elimination

The FAW Russian Lower Mirror system is a specialized visual safety array engineered for the FAW CA3250P66K24L1TE5Z dump truck. Designed to conquer the “No-Zone” dangers inherent in heavy-duty mining operations, this assembly integrates Class IV and Class V optics to provide a panoramic view of the vehicle’s immediate perimeter. By utilizing the FAW Russian Lower Mirror, operators can navigate tight weighbridges and crowded loading zones in the Arctic with absolute precision, mitigating collision risks in temperatures as low as -50°C.

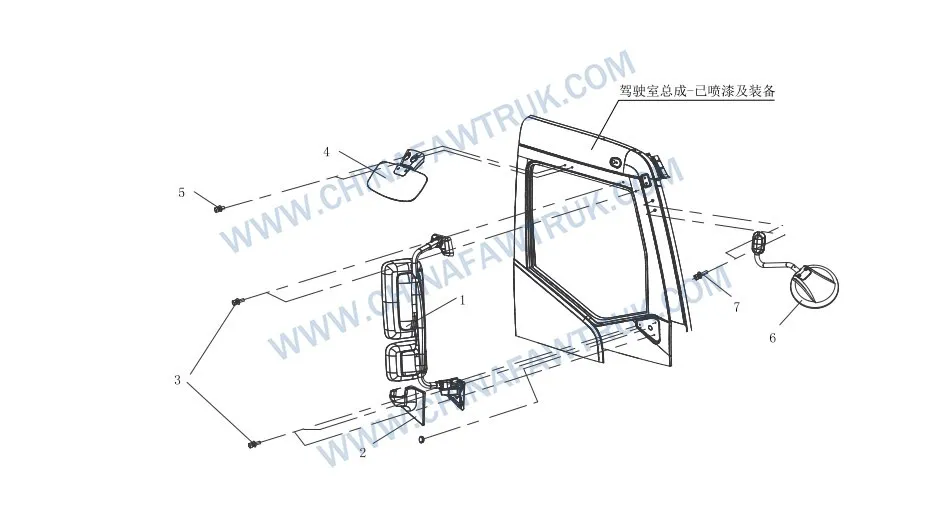

FAW Russian Lower Mirror

| No. |

Part Number |

Part Name |

Qty |

| 1 |

8202020BA01 |

Right External Rearview Mirror Assembly |

1 |

| – |

8202020CA01 |

Right External Rearview Mirror Assembly |

1 |

| 2 |

8202022-A01 |

Right Lower Fixing Base Decoration Cover |

1 |

| 3 |

T2180630F6 |

Hexagon Socket Head Cap Combination Screw |

5 |

| 4 |

8219010-A01-C00 |

Downward View Mirror Assembly |

1 |

| – |

8219010AA01 |

Downward View Mirror Assembly |

1 |

| 5 |

T2180625F6 |

Hexagon Socket Head Cap Combination Screw |

2 |

| 6 |

8219020-A01 |

Front Lower View Mirror Assembly |

1 |

| – |

8219020AA01 |

Front Lower View Mirror Assembly |

1 |

| 7 |

T2180650F6 |

Hexagon Socket Head Cap Combination Screw |

2 |

Class IV Optics: The Downward View Mirror

The cornerstone of the FAW Russian Lower Mirror system is the Downward View Mirror Assembly (Part No. 8219010-A01-C00). Known in technical terms as the “Class IV” wide-angle mirror, this component is strategically mounted high on the passenger door frame. Its primary function is to cast a visual net over the notorious “death zone” immediately adjacent to the cab. In the context of the massive J6P dump truck, this area is completely invisible to the driver using standard mirrors, posing a severe risk to personnel.

The Downward View Mirror Assembly utilizes a highly convex glass substrate with a specific radius of curvature. This geometry is designed to intentionally distort the image, compressing a wide field of view into a compact frame. This optical engineering allows the driver to see the front right tire, the fuel tank guard, and any pedestrians standing dangerously close to the vehicle’s flank. Such visibility is essential for the FAW Russian Lower Mirror to function effectively as a primary safety device in crowded mining sites.

For the Russian Arctic specification, FAW offers an alternative variant, the Downward View Mirror Assembly (Part No. 8219010AA01). This version typically features enhanced cold-weather resilience, including a specialized backing plate that resists thermal warping. When ambient temperatures swing from -40°C to the localized heat of the engine bay, standard mirror housings can flex, causing the glass to pop out. The FAW Russian Lower Mirror housing is molded from a high-impact ABS composite that maintains its dimensional stability in these extremes, ensuring year-round reliability.

The positioning of the Downward View Mirror Assembly includes a robust adjustment mechanism. The internal friction ball joint of the FAW Russian Lower Mirror is engineered with a high-torque clamping threshold. This ensures that the mirror does not “droop” or drift out of alignment when the truck hits a pothole or traverses a washboard haul road. Maintaining a static image is vital for safety; a vibrating mirror induces eye strain and nausea, significantly reducing the driver’s overall alertness and reaction time during long shifts.

Class V Optics: The Front Lower View Mirror

Complementing the side coverage is the Front Lower View Mirror Assembly (Part No. 8219020-A01), classified as the “Class V” proximity mirror. Positioned above the windshield or on the upper A-pillar, this mirror is tasked with revealing the area directly in front of the massive steel bumper. In off-road applications, this zone is critical. Large boulders, deep ruts, or even smaller service vehicles can be completely obscured by the J6P’s high bonnet. The Front Lower View Mirror Assembly provides the driver with the necessary visual confirmation to inch forward in tight loading bays.

Like its counterpart, the Front Lower View Mirror Assembly (Part No. 8219020AA01) is engineered for optical clarity under duress. The convex lens is manufactured to strict ISO standards to minimize edge distortion, which can be disorienting. In the FAW Russian Lower Mirror system, the glass is often treated with a hydrophobic coating that repels water and slush. This coating is vital during the Russian spring thaw, where dirty road spray can quickly render a standard mirror useless, blinding the driver to frontal hazards.

The specialized coating on the Front Lower View Mirror Assembly causes water droplets to bead up and roll off instantly. This ensures that the driver retains a clear view of the ground in front of the wheels at all times. Without this feature, the FAW Russian Lower Mirror would require constant manual cleaning, exposing the driver to the elements. This self-cleaning capability is a testament to the practical engineering focused on maximizing operational uptime in difficult environmental conditions.

The structural arm holding the Front Lower View Mirror Assembly is designed to withstand significant wind load. As the vehicle travels at highway speeds, the air pressure on this protruding component is immense. To prevent aerodynamic buffeting, the arm is profiled to slice through the air, and the housing of the FAW Russian Lower Mirror is shaped to reduce turbulence. This aerodynamic consideration not only stabilizes the image but also reduces wind noise entering the cabin, contributing to a less fatiguing driving environment.

Precision Fastening: Securing the Vision

The efficacy of the FAW Russian Lower Mirror relies entirely on the security of its mounting. The system utilizes specific high-tensile fasteners, notably the Hexagon Socket Head Cap Combination Screw (Part No. T2180625F6) for the side mirror. Additionally, the Hexagon Socket Head Cap Combination Screw (Part No. T2180650F6) is used for the front mirror assembly. The difference in part numbers indicates precise length variations tailored to the specific depth of the mounting bosses on the cab frame.

Using a generic bolt of incorrect length can lead to bottoming out, leaving the bracket loose, or insufficient thread engagement, which strips the hole. Both scenarios compromise the stability of the Downward View Mirror Assembly. The term “Combination Screw” is significant in the FAW Russian Lower Mirror BOM. It denotes that the Hexagon Socket Head Cap Combination Screw comes pre-assembled with a captive flat washer and a split spring washer, integrated into a single unit.

This integration is a critical quality control feature for the FAW Russian Lower Mirror. In the rush of field repairs, mechanics might drop or forget a separate washer. The captive design ensures that the locking mechanism—the spring washer—is always present. This spring tension is vital for maintaining clamping force on the Front Lower View Mirror Assembly bracket as the metal expands and contracts with the extreme temperature fluctuations of the Russian climate, preventing the mirror from vibrating loose.

Moreover, the “F6” suffix on the Hexagon Socket Head Cap Combination Screw specifies a high-grade anti-corrosion surface treatment, such as a zinc-flake or Geomet coating. Standard zinc plating would quickly succumb to the road salts and magnesium chloride used for de-icing in Russia. The specialized coating on these screws ensures that the Downward View Mirror Assembly remains serviceable throughout the vehicle’s life. This prevents rusted-in bolts, which turn a simple replacement into a major repair task.

Material Science and Arctic Durability

The materials chosen for the FAW Russian Lower Mirror components are dictated by the “Russian Cold Zone” requirements. The housing of the Downward View Mirror Assembly is made from an ASA (Acrylonitrile Styrene Acrylate) polymer blend. Unlike standard ABS, ASA offers superior resistance to UV radiation and environmental stress cracking. In the high-altitude, high-UV environment of open-pit mines, standard plastics chalk and become brittle within months. The ASA housing maintains its ductility, preserving the expensive optical glass inside.

The glass substrate itself in the FAW Russian Lower Mirror is also chemically toughened. This process increases the surface compression of the glass, making it more resistant to stone chips and scratches from abrasive dust. Furthermore, the reflective backing is sealed with a heavy-duty epoxy paint to prevent “edge creep”—the black corrosion that starts at the mirror’s edge. This sealing is particularly important for the Downward View Mirror Assembly, which hangs lower and is exposed to a denser cloud of corrosive road spray.

Finally, the gasket materials used to seal the glass into the housing of the Front Lower View Mirror Assembly are formulated from EPDM rubber. This synthetic rubber remains flexible at -50°C, maintaining a watertight seal around the lens. If this seal were to fail, water would ingress, freeze, and pop the glass out of the frame. The use of high-grade EPDM ensures that the FAW Russian Lower Mirror remains a sealed, cohesive unit, protecting the clarity of the driver’s view regardless of the weather conditions.

Conclusion: Total Visual Command

The FAW Russian Lower Mirror assembly is not merely an accessory; it is a fundamental component of the J6P’s active safety architecture. By effectively eliminating blind spots with the Downward View Mirror Assembly and the Front Lower View Mirror Assembly, FAW empowers operators to work confidently in confined and hazardous spaces. The robust engineering of the mounting hardware, specifically the Hexagon Socket Head Cap Combination Screw, ensures that this visibility is maintained despite the brutal vibration and cold of the Russian Arctic.

For fleet managers, the lesson is clear: compromise on visibility is a compromise on safety. Replacing a damaged Downward View Mirror Assembly with a generic, ill-fitting part introduces distortion and vibration that can lead to accidents. By adhering to the genuine parts list and ensuring every Hexagon Socket Head Cap Combination Screw is torqued to spec, maintenance teams guarantee that the FAW Russian Lower Mirror system continues to protect the truck, the driver, and the surrounding workforce, shift after grueling shift.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.