Right Exterior Rearview Mirror: Integrating 10 Strategic Optical Components for Uncompromised Arctic Safety

The Right Exterior Rearview Mirror assembly for the FAW CA3250P66K24L1TE5Z dump truck is a comprehensive visibility system designed to eliminate the notorious “blind side” risks associated with heavy-duty operations. In the Russian Arctic, where whiteout conditions and long nights prevail, this assembly is not just a reflector; it is a multi-tiered optical array. By combining the primary Right Exterior Rearview Mirror with specialized downward and front-view optics, FAW ensures that operators maintain total spatial awareness, safeguarding both the vehicle and personnel in temperatures as low as -50°C.

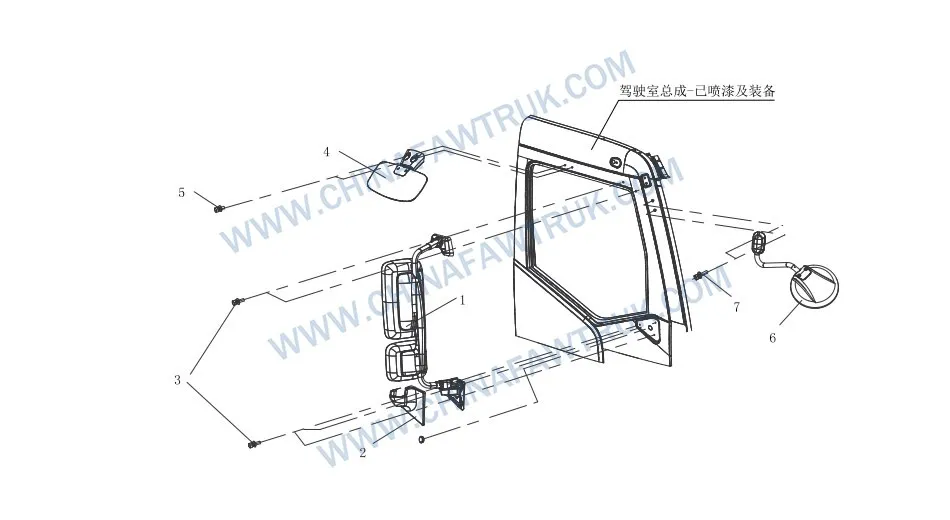

Right Exterior Rearview Mirror

| No. |

Part Number |

Part Name |

Qty |

| 1 |

8202020BA01 |

Right External Rearview Mirror Assembly |

1 |

| – |

8202020CA01 |

Right External Rearview Mirror Assembly |

1 |

| 2 |

8202022-A01 |

Right Lower Fixing Base Decoration Cover |

1 |

| 3 |

T2180630F6 |

Hexagon Socket Head Cap Combination Screw |

5 |

| 4 |

8219010-A01-C00 |

Downward View Mirror Assembly |

1 |

| – |

8219010AA01 |

Downward View Mirror Assembly |

1 |

| 5 |

T2180625F6 |

Hexagon Socket Head Cap Combination Screw |

2 |

| 6 |

8219020-A01 |

Front Lower View Mirror Assembly |

1 |

| – |

8219020AA01 |

Front Lower View Mirror Assembly |

1 |

| 7 |

T2180650F6 |

Hexagon Socket Head Cap Combination Screw |

2 |

Primary Optics and Thermal Management

The Right Exterior Rearview Mirror system is anchored by the Right External Rearview Mirror Assembly (Part No. 8202020BA01), a component critical for monitoring the passenger side of the vehicle. In Left-Hand Drive configurations typical for Russia, this is the “blind side,” making the optical quality of this mirror a matter of life and death. The glass substrate is engineered to eliminate edge distortion, ensuring that the driver can accurately judge the distance of overtaking vehicles or structural hazards in the quarry. The Right Exterior Rearview Mirror provides a wide field of view that integrates seamlessly with the driver’s peripheral vision, reducing the cognitive load required to monitor the vehicle’s surroundings.

A defining feature of the Right External Rearview Mirror Assembly in the Russian specification is its advanced heating capability. Standard mirrors often fail in the Arctic because the heating elements are too weak or unevenly distributed, leaving “cold spots” where ice accumulates. The Right Exterior Rearview Mirror utilizes a high-density resistance mesh bonded directly to the backing of the glass. This system provides rapid, uniform thermal transfer, capable of sublimating frost and melting ice sheets even when ambient temperatures plummet to -50°C. This ensures that the Right Exterior Rearview Mirror is operational within minutes of engine start, preventing the hazardous practice of manually scraping ice which can scratch the optical surface.

FAW also provides an alternative specification, the Right External Rearview Mirror Assembly (Part No. 8202020CA01), which may feature different curvature ratios or anti-glare coatings depending on the specific mining application. The anti-glare technology is particularly vital in snow-covered environments where the albedo effect (reflection of sunlight off snow) is intense. By filtering out high-energy blue light, the Right Exterior Rearview Mirror reduces eye strain during long day shifts, preserving the driver’s visual acuity. This attention to optical health underscores the role of the Right Exterior Rearview Mirror as a sophisticated instrument of safety rather than a simple accessory.

Blind Spot Elimination: The Auxiliary Array

Comprehensive visibility requires more than just looking back; it requires looking down. The Right Exterior Rearview Mirror system incorporates the Downward View Mirror Assembly (Part No. 8219010-A01-C00), often referred to as the “class IV” wide-angle mirror. Mounted high on the A-pillar or the door frame, this convex mirror provides a fish-eye view of the area immediately adjacent to the passenger door and the front right wheel. This zone is notoriously dangerous for pedestrians and smaller vehicles which can easily disappear below the driver’s line of sight. The Downward View Mirror Assembly eliminates this blind spot, allowing the driver to navigate tight weighbridge stations and workshop bays with precision.

Complementing this is the Front Lower View Mirror Assembly (Part No. 8219020-A01), also known as the “class V” proximity mirror. Positioned to view the area directly in front of the bumper, this component is essential for off-road maneuvering where hidden rocks or deep ruts can damage the chassis. The integration of the Front Lower View Mirror Assembly with the main Right Exterior Rearview Mirror creates a seamless “visual safety net” around the front right corner of the truck. FAW engineers have tuned the convexity of the Front Lower View Mirror Assembly to maximize the viewing angle without creating disorienting distortion, a balance that is difficult to achieve in inferior aftermarket replacements.

The structural rigidity of the brackets holding the Downward View Mirror Assembly and the Front Lower View Mirror Assembly is paramount. These mirrors hang in the airflow and are subject to significant wind buffeting. To prevent vibration from blurring the image, the mounting arms are constructed from reinforced steel or high-strength polymer composites. A vibrating Right Exterior Rearview Mirror or auxiliary mirror causes eye fatigue and nausea; therefore, the dampening characteristics of these assemblies are tuned to the resonant frequency of the J6P chassis, ensuring a stable image even on washboard haul roads.

Housing Durability and Aerodynamics

The housing of the Right Exterior Rearview Mirror is the first line of defense against the harsh Arctic environment. The outer shell is molded from an impact-modified ABS/ASA polymer blend, specifically formulated to retain ductility at cryogenic temperatures. Standard plastics become brittle and glass-like in the Russian winter, shattering upon impact with gravel or ice chunks. The material used for the Right External Rearview Mirror Assembly absorbs impact energy, protecting the delicate internal motor mechanisms and heating circuits. This durability ensures that the Right Exterior Rearview Mirror survives the inevitable knocks and scrapes of mining operations.

Aerodynamics plays a crucial functional role in the design of the Right Exterior Rearview Mirror housing. The shape is wind-tunnel tested to control the airflow separation point. By creating a laminar flow around the mirror face, the design utilizes air pressure to deflect road spray, mud, and falling snow away from the lens. This “self-cleaning” aerodynamic profile significantly reduces the frequency with which the driver must stop to wipe the Right Exterior Rearview Mirror, thereby maintaining operational efficiency and reducing exposure to the cold.

The interface between the mirror housing and the door is protected by the Right Lower Fixing Base Decoration Cover (Part No. 8202022-A01). This component is not merely decorative; it serves as a streamlined fairing that reduces wind noise—a significant contributor to driver fatigue. Moreover, the Right Lower Fixing Base Decoration Cover seals the mounting points, preventing the ingress of water and corrosive de-icing salts into the door cavity. By shielding the structural bolts, this cover ensures that the Right Exterior Rearview Mirror can be easily serviced even after years of exposure to saline slush.

Precision Fastening Technology

The reliability of the Right Exterior Rearview Mirror installation is guaranteed by a specific set of high-grade fasteners. The assembly utilizes the Hexagon Socket Head Cap Combination Screw (Part No. T2180630F6) for the main mounting points. The term “Combination Screw” indicates the integration of a captive flat washer and a spring lock washer. This design is critical for the Right Exterior Rearview Mirror because it prevents the washers from being dropped or forgotten during field repairs. The captive spring washer provides constant tension, compensating for the thermal contraction of the metal parts in extreme cold, preventing the mirror from vibrating loose.

For the auxiliary mirrors, different lengths of fasteners are specified, such as the Hexagon Socket Head Cap Combination Screw (Part No. T2180625F6) and (Part No. T2180650F6). The precise length is essential; a screw that is too long could bottom out in the blind hole before securing the bracket, while a screw that is too short may strip the threads under wind load. The “F6” designation on these screws refers to a high-performance anti-corrosion coating, likely a zinc-flake or Geomet finish. This is vastly superior to standard galvanizing, ensuring that the fasteners of the Right Exterior Rearview Mirror do not seize due to rust, facilitating easy replacement.

The use of a Hexagon Socket Head drive allows for the application of high torque values using an Allen key, ensuring a rigid connection for the Right Exterior Rearview Mirror. This rigidity is essential for maintaining the alignment of the Downward View Mirror Assembly and the Front Lower View Mirror Assembly. Even a fraction of a degree of movement at the mounting base translates to a significant shift in the field of view. By using these specialized combination screws, FAW ensures that the optical geometry of the Right Exterior Rearview Mirror system remains fixed, regardless of the chassis vibration or wind pressure encountered on the road.

Conclusion: A Vital Component for Arctic Safety

The Right Exterior Rearview Mirror assembly is a cornerstone of the FAW J6P’s safety architecture. It transforms the passive act of checking mirrors into an active safety protocol. By integrating the heated clarity of the Right External Rearview Mirror Assembly with the blind-spot elimination of the Downward View Mirror Assembly and the Front Lower View Mirror Assembly, FAW delivers a comprehensive solution for the Russian market. Every component, from the Right Lower Fixing Base Decoration Cover to the specialized Hexagon Socket Head Cap Combination Screw, is engineered to withstand the rigors of the Arctic.

For fleet managers, ensuring the integrity of the Right Exterior Rearview Mirror is non-negotiable. Substituting these calibrated assemblies with generic aftermarket parts compromises visibility and safety. Only by maintaining the Right Exterior Rearview Mirror with genuine FAW components can operators ensure that their drivers possess the situational awareness necessary to navigate the hazardous environment of a mining site safely. This system is not just about compliance; it is about bringing every driver home safely after every shift in the frozen north.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.