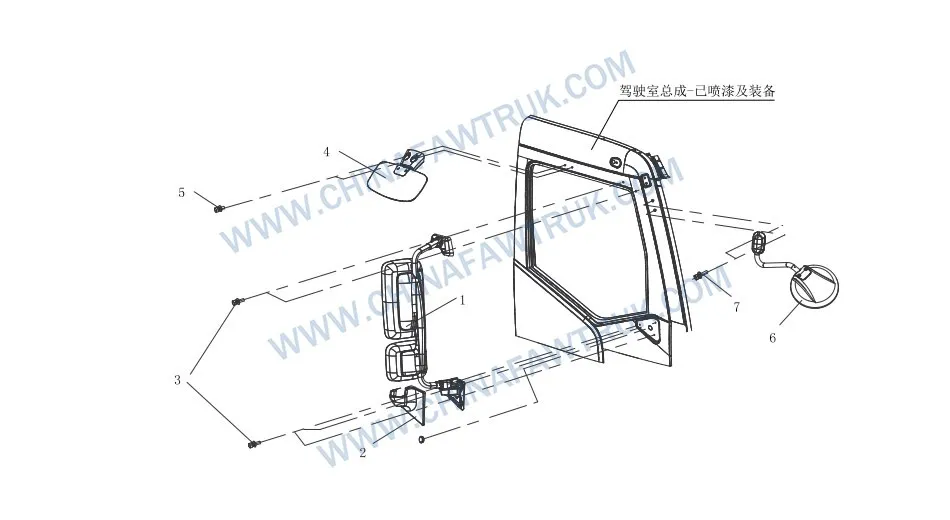

مرآة الرؤية الخلفية الخارجية اليمنى: التكامل 10 المكونات البصرية الاستراتيجية للسلامة التامة في القطب الشمالي

ال مرآة الرؤية الخلفية الخارجية اليمنى إن تجميع الشاحنة القلابة FAW CA3250P66K24L1TE5Z عبارة عن نظام رؤية شامل مصمم للتخلص من العيوب سيئة السمعة “الجانب الأعمى” المخاطر المرتبطة بالعمليات الثقيلة. في القطب الشمالي الروسي, حيث تسود ظروف البياض والليالي الطويلة, هذا التجمع ليس مجرد عاكس; إنها مجموعة بصرية متعددة المستويات. من خلال الجمع بين الابتدائي مرآة الرؤية الخلفية الخارجية اليمنى مع بصريات الرؤية السفلية والأمامية المتخصصة, تضمن FAW أن يحافظ المشغلون على الوعي المكاني الكامل, حماية كل من السيارة والأفراد في درجات حرارة منخفضة تصل إلى -50 درجة مئوية.

مرآة الرؤية الخلفية الخارجية اليمنى

| لا. |

رقم الجزء |

جزء اسم |

الكمية |

| 1 |

8202020BA01 |

مجموعة مرآة الرؤية الخلفية الخارجية اليمنى |

1 |

| – |

8202020CA01 |

مجموعة مرآة الرؤية الخلفية الخارجية اليمنى |

1 |

| 2 |

8202022-أ01 |

غطاء تزيين قاعدة التثبيت السفلية اليمنى |

1 |

| 3 |

T2180630F6 |

مسدس مزيج غطاء الرأس المقبس المسمار |

5 |

| 4 |

8219010-A01-C00 |

مجموعة مرآة الرؤية السفلية |

1 |

| – |

8219010AA01 |

مجموعة مرآة الرؤية السفلية |

1 |

| 5 |

T2180625F6 |

مسدس مزيج غطاء الرأس المقبس المسمار |

2 |

| 6 |

8219020-أ01 |

مجموعة مرآة الرؤية السفلية الأمامية |

1 |

| – |

8219020AA01 |

مجموعة مرآة الرؤية السفلية الأمامية |

1 |

| 7 |

T2180650F6 |

مسدس مزيج غطاء الرأس المقبس المسمار |

2 |

البصريات الأولية والإدارة الحرارية

ال مرآة الرؤية الخلفية الخارجية اليمنى يرتكز النظام على مجموعة مرآة الرؤية الخلفية الخارجية اليمنى (الجزء لا. 8202020BA01), مكون حاسم لمراقبة جانب الركاب من السيارة. في تكوينات محرك اليد اليسرى النموذجية لروسيا, هذا هو “الجانب الأعمى,” مما يجعل الجودة البصرية لهذه المرآة مسألة حياة أو موت. تم تصميم الركيزة الزجاجية للتخلص من تشويه الحواف, التأكد من أن السائق يمكنه الحكم بدقة على مسافة تجاوز المركبات أو المخاطر الهيكلية في المحجر. ال مرآة الرؤية الخلفية الخارجية اليمنى يوفر مجال رؤية واسعًا يتكامل بسلاسة مع الرؤية المحيطية للسائق, تقليل الحمل المعرفي المطلوب لمراقبة محيط السيارة.

السمة المميزة لل مجموعة مرآة الرؤية الخلفية الخارجية اليمنى في المواصفات الروسية هي قدرتها على التسخين المتقدمة. غالبًا ما تفشل المرايا القياسية في القطب الشمالي لأن عناصر التسخين ضعيفة جدًا أو موزعة بشكل غير متساوٍ, مغادرة “البقع الباردة” حيث يتراكم الجليد. ال مرآة الرؤية الخلفية الخارجية اليمنى يستخدم شبكة مقاومة عالية الكثافة مرتبطة مباشرة بالجزء الخلفي من الزجاج. يوفر هذا النظام سريعًا, نقل حراري موحد, قادر على تسامي الصقيع وذوبان الصفائح الجليدية حتى عندما تنخفض درجات الحرارة المحيطة إلى -50 درجة مئوية. وهذا يضمن أن مرآة الرؤية الخلفية الخارجية اليمنى يعمل خلال دقائق من بدء تشغيل المحرك, منع الممارسة الخطرة المتمثلة في كشط الجليد يدويًا والذي قد يؤدي إلى خدش السطح البصري.

توفر FAW أيضًا مواصفات بديلة, ال مجموعة مرآة الرؤية الخلفية الخارجية اليمنى (الجزء لا. 8202020CA01), والتي قد تتميز بنسب انحناء مختلفة أو طلاءات مضادة للوهج اعتمادًا على تطبيق التعدين المحدد. تعتبر التكنولوجيا المضادة للوهج حيوية بشكل خاص في البيئات المغطاة بالثلوج حيث يكون هناك تأثير البياض (انعكاس ضوء الشمس على الثلج) مكثفة. عن طريق تصفية الضوء الأزرق عالي الطاقة, ال مرآة الرؤية الخلفية الخارجية اليمنى يقلل من إجهاد العين خلال نوبات النهار الطويلة, الحفاظ على حدة البصر للسائق. ويؤكد هذا الاهتمام بالصحة البصرية دور مرآة الرؤية الخلفية الخارجية اليمنى كأداة متطورة للسلامة بدلاً من مجرد ملحق بسيط.

القضاء على النقطة العمياء: المصفوفة المساعدة

تتطلب الرؤية الشاملة أكثر من مجرد النظر إلى الوراء; يتطلب النظر إلى الأسفل. ال مرآة الرؤية الخلفية الخارجية اليمنى يتضمن النظام مجموعة مرآة الرؤية السفلية (الجزء لا. 8219010-A01-C00), غالبا ما يشار إليها باسم “الدرجة الرابعة” مرآة واسعة الزاوية. يتم تركيبه عالياً على العمود A أو إطار الباب, توفر هذه المرآة المحدبة رؤية عين السمكة للمنطقة المجاورة مباشرة لباب الراكب والعجلة الأمامية اليمنى. تعتبر هذه المنطقة خطرة على المشاة والمركبات الصغيرة التي يمكن أن تختفي بسهولة تحت خط رؤية السائق. ال مجموعة مرآة الرؤية السفلية يزيل هذه النقطة العمياء, مما يسمح للسائق بالتنقل في محطات الميزان الضيقة وخلجان الورش بدقة.

تكمل هذا هو مجموعة مرآة الرؤية السفلية الأمامية (الجزء لا. 8219020-أ01), المعروف أيضا باسم “الفئة الخامسة” مرآة القرب. تم وضعه لرؤية المنطقة مباشرة أمام المصد, يعد هذا المكون ضروريًا للمناورة على الطرق الوعرة حيث يمكن للصخور المخفية أو الأخاديد العميقة أن تلحق الضرر بالهيكل. التكامل مجموعة مرآة الرؤية السفلية الأمامية مع الرئيسي مرآة الرؤية الخلفية الخارجية اليمنى يخلق سلس “شبكة أمان بصرية” حول الزاوية اليمنى الأمامية للشاحنة. قام مهندسو FAW بضبط تحدب مجموعة مرآة الرؤية السفلية الأمامية لتعظيم زاوية المشاهدة دون خلق تشويه مربك, توازن يصعب تحقيقه في بدائل ما بعد البيع الرديئة.

الصلابة الهيكلية للأقواس التي تحمل مجموعة مرآة الرؤية السفلية و مجموعة مرآة الرؤية السفلية الأمامية أمر بالغ الأهمية. هذه المرايا معلقة في تدفق الهواء وتتعرض لضربات قوية من الرياح. لمنع الاهتزاز من عدم وضوح الصورة, أذرع التثبيت مصنوعة من الفولاذ المقوى أو مركبات البوليمر عالية القوة. تهتز مرآة الرؤية الخلفية الخارجية اليمنى أو المرآة المساعدة تسبب تعب العين والغثيان; لذلك, يتم ضبط خصائص التخميد لهذه التجميعات على تردد الرنين لهيكل J6P, ضمان صورة مستقرة حتى على طرق النقل.

متانة السكن والديناميكا الهوائية

السكن مرآة الرؤية الخلفية الخارجية اليمنى هو خط الدفاع الأول ضد بيئة القطب الشمالي القاسية. الغلاف الخارجي مصبوب من مزيج بوليمر ABS/ASA المعدل بالصدمات, تم تصميمه خصيصًا للحفاظ على الليونة في درجات الحرارة المبردة. تصبح المواد البلاستيكية القياسية هشة وتشبه الزجاج في الشتاء الروسي, تتحطم عند الاصطدام بالحصى أو قطع الجليد. المواد المستخدمة لل مجموعة مرآة الرؤية الخلفية الخارجية اليمنى يمتص طاقة التأثير, حماية آليات المحرك الداخلية الدقيقة ودوائر التسخين. تضمن هذه المتانة أن مرآة الرؤية الخلفية الخارجية اليمنى ينجو من الضربات والخدوش التي لا مفر منها لعمليات التعدين.

تلعب الديناميكا الهوائية دورًا وظيفيًا حاسمًا في تصميم السيارة مرآة الرؤية الخلفية الخارجية اليمنى الإسكان. تم اختبار الشكل على شكل نفق رياح للتحكم في نقطة فصل تدفق الهواء. من خلال خلق تدفق الصفحي حول وجه المرآة, يستخدم التصميم ضغط الهواء لتشتيت رذاذ الطريق, الطين, وتساقط الثلوج بعيدا عن العدسة. هذا “التنظيف الذاتي” يقلل المظهر الديناميكي الهوائي بشكل كبير من التردد الذي يجب أن يتوقف به السائق لمسح السيارة مرآة الرؤية الخلفية الخارجية اليمنى, وبالتالي الحفاظ على الكفاءة التشغيلية وتقليل التعرض للبرد.

الواجهة بين مبيت المرآة والباب محمية بواسطة غطاء تزيين قاعدة التثبيت السفلية اليمنى (الجزء لا. 8202022-أ01). هذا العنصر ليس مجرد ديكور; فهو بمثابة هدية انسيابية تقلل من ضوضاء الرياح - وهو ما يساهم بشكل كبير في إرهاق السائق. علاوة على ذلك, ال غطاء تزيين قاعدة التثبيت السفلية اليمنى يختم نقاط التثبيت, منع دخول الماء وأملاح إزالة الجليد المسببة للتآكل إلى تجويف الباب. عن طريق حماية البراغي الهيكلية, يضمن هذا الغطاء أن مرآة الرؤية الخلفية الخارجية اليمنى يمكن صيانتها بسهولة حتى بعد سنوات من التعرض للطين الملحي.

تقنية التثبيت الدقيق

موثوقية مرآة الرؤية الخلفية الخارجية اليمنى يتم ضمان التثبيت من خلال مجموعة محددة من السحابات عالية الجودة. يستخدم التجمع مسدس مزيج غطاء الرأس المقبس المسمار (الجزء لا. T2180630F6) لنقاط التثبيت الرئيسية. على المدى “برغي مركب” يشير إلى تكامل الغسالة المسطحة الأسيرة وغسالة القفل الزنبركي. هذا التصميم أمر بالغ الأهمية ل مرآة الرؤية الخلفية الخارجية اليمنى لأنه يمنع الغسالات من السقوط أو النسيان أثناء الإصلاحات الميدانية. توفر غسالة الزنبرك الأسيرة توترًا مستمرًا, تعويض الانكماش الحراري للأجزاء المعدنية في البرد الشديد, منع المرآة من الاهتزاز بشكل فضفاض.

للمرايا المساعدة, يتم تحديد أطوال مختلفة من السحابات, مثل مسدس مزيج غطاء الرأس المقبس المسمار (الجزء لا. T2180625F6) و (الجزء لا. T2180650F6). الطول الدقيق ضروري; يمكن أن يصل المسمار الطويل جدًا إلى أسفل في الفتحة المسدودة قبل تثبيت الدعامة, في حين أن المسمار القصير جدًا قد يؤدي إلى تجريد الخيوط تحت حمل الرياح. ال “F6” يشير التعيين الموجود على هذه البراغي إلى طلاء مضاد للتآكل عالي الأداء, من المحتمل أن يكون تشطيبًا برقائق الزنك أو Geomet. هذا يتفوق إلى حد كبير على الجلفنة القياسية, التأكد من أن مثبتات مرآة الرؤية الخلفية الخارجية اليمنى لا تغتنم بسبب الصدأ, تسهيل الاستبدال السهل.

استخدام أ رأس مقبس سداسي يسمح محرك الأقراص بتطبيق قيم عزم دوران عالية باستخدام مفتاح Allen, ضمان اتصال جامد ل مرآة الرؤية الخلفية الخارجية اليمنى. هذه الصلابة ضرورية للحفاظ على محاذاة مجموعة مرآة الرؤية السفلية و مجموعة مرآة الرؤية السفلية الأمامية. حتى جزء بسيط من درجة الحركة عند قاعدة التركيب يُترجم إلى تحول كبير في مجال الرؤية. باستخدام هذه البراغي المركبة المتخصصة, يضمن FAW أن الهندسة البصرية لل مرآة الرؤية الخلفية الخارجية اليمنى يبقى النظام ثابتا, بغض النظر عن اهتزاز الهيكل أو ضغط الرياح الذي تواجهه على الطريق.

خاتمة: عنصر حيوي للسلامة في القطب الشمالي

ال مرآة الرؤية الخلفية الخارجية اليمنى يعد التجميع حجر الزاوية في بنية السلامة الخاصة بـ FAW J6P. إنه يحول الفعل السلبي المتمثل في فحص المرايا إلى بروتوكول أمان نشط. من خلال دمج الوضوح الساخن لل مجموعة مرآة الرؤية الخلفية الخارجية اليمنى مع القضاء على النقطة العمياء مجموعة مرآة الرؤية السفلية و مجموعة مرآة الرؤية السفلية الأمامية, تقدم FAW حلاً شاملاً للسوق الروسية. كل مكون, من غطاء تزيين قاعدة التثبيت السفلية اليمنى الى المتخصصة مسدس مزيج غطاء الرأس المقبس المسمار, تم تصميمه ليتحمل قسوة القطب الشمالي.

لمديري الأسطول, ضمان سلامة مرآة الرؤية الخلفية الخارجية اليمنى غير قابل للتفاوض. إن استبدال هذه المجموعات المعايرة بأجزاء ما بعد البيع العامة يؤدي إلى إضعاف الرؤية والسلامة. فقط من خلال الحفاظ على مرآة الرؤية الخلفية الخارجية اليمنى باستخدام مكونات FAW الأصلية، يمكن للمشغلين التأكد من أن سائقيهم يمتلكون الوعي الظرفي اللازم للتنقل في البيئة الخطرة لموقع التعدين بأمان. هذا النظام لا يقتصر فقط على الامتثال; يتعلق الأمر بإعادة كل سائق إلى منزله بأمان بعد كل نوبة عمل في الشمال المتجمد.

التعبئة والتغليف والخدمات اللوجستية

أجزاء فاو, بما في ذلك مجموعة كتلة الأسطوانة, يتم تعبئتها بعناية لضمان الولادة الآمنة. يتم تأمين كل مكون في مواد واقية لمنع الضرر أثناء النقل. تضمن الشبكة اللوجستية الشحنات في الوقت المناسب في جميع أنحاء العالم, دعم عمليات الصيانة الفعالة. فيما يلي صورة توضح العبوة القياسية لقطع غيار شاحنات FAW, إظهار الاهتمام بالتفاصيل في التعامل والتخزين.

يقلل أسلوب التغليف هذا من مخاطر التآكل أو التلف الناتج عن الصدمات, ضمان وصول أجزاء مثل FAW Cylinder Block Assembly في حالة ممتازة. يمكن للعملاء الاعتماد على الخدمات اللوجستية التي تقدمها FAW للحصول على الجودة والموثوقية المتسقة.