FAW Russian Electric Horn Assembly: Orchestrating 9 Precision Components for Reliable Urban Signaling

The FAW Russian Electric Horn assembly serves as the primary acoustic warning device for city driving and low-speed maneuvering in the CA3250P66K24L1TE5Z dump truck. Unlike the powerful air horns used for open-pit mining, this electric unit provides a distinct, immediate signal compliant with urban noise regulations. Designed for the Russian climate, the FAW Russian Electric Horn features moisture-sealed internal circuitry and corrosion-resistant mounting hardware to ensure consistent operation even when coated in road salt and slush. This guide breaks down the electromagnetic components and structural brackets that define its reliability.

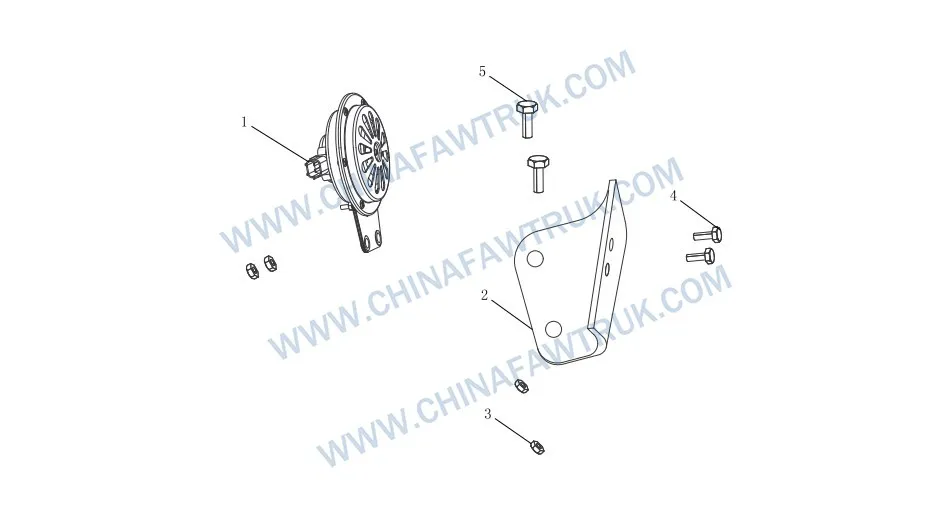

FAW Russian Electric Horn

| No. |

Part Number |

Part Name |

Qty |

| 1 | 3721010-116 | High Pitch Electric Horn Assembly | 1 |

| 2 | 3721211-50A | Electric Horn Bracket | 1 |

| 3 | CQ34008 | Hexagon Nut | 4 |

| 4 | Q1840820 | Hexagon Flange Bolt (Coarse Shank/Standard) | 2 |

| 5 | Q1840825 | Hexagon Flange Bolt (Coarse Shank/Standard) | 2 |

Electromagnetic Actuation and Tone Generation

The core of the FAW Russian Electric Horn is a sophisticated electromagnetic solenoid housed within the High Pitch Electric Horn Assembly (Part No. 3721010-116). When the driver presses the horn button, current energizes the solenoid, pulling a steel diaphragm towards a magnetic core. As the diaphragm moves, it breaks the electrical contact, de-energizing the magnet and allowing the diaphragm to spring back. This rapid oscillation occurs hundreds of times per second, generating the fundamental frequency.

For the Russian market, the “116” specification denotes a high-pitch tuning (typically around 400-500 Hz). This frequency is chosen because it propagates well in dense, cold air and is distinctly audible over the low-frequency rumble of heavy diesel traffic. Unlike air horns which can freeze if moisture enters the valve, the FAW Russian Electric Horn is an instantaneous, solid-state device. Its sealed construction prevents ice from forming on the diaphragm, ensuring that the horn sounds immediately even after the truck has been parked overnight in -40°C weather.

The sound projection is amplified by a scroll-shaped resonator, often called a “snail” housing. In the FAW Russian Electric Horn design, this plastic or metal housing is oriented downwards to allow gravity drainage of any water or snowmelt. This self-clearing capability is crucial; if water accumulates and freezes inside the scroll, the horn will be muffled or silent. The material of the resonator is impact-resistant to withstand stone chips from the road, preserving the acoustic integrity of the assembly.

Mounting and Vibration Isolation

Mounting an electric horn on a vibrating diesel chassis requires a delicate balance. The horn must be secure, yet it must be allowed to vibrate freely to generate sound. The Electric Horn Bracket (Part No. 3721211-50A) is engineered as a leaf spring. It is rigid enough to hold the horn in position but flexible enough to act as a mechanical filter. This isolation prevents the engine’s vibration from dampening the horn’s oscillation, which would result in a weak or flat tone.

The bracket is secured to the vehicle using Hexagon Flange Bolt (Coarse Shank/Standard) units (Part No. Q1840820 and Q1840825). The use of flange bolts distributes the clamping load, preventing the bracket from cracking at the mounting hole—a common failure point in high-vibration environments. The “Coarse Shank” thread profile provides superior grip in the chassis weld nut, resisting the tendency to back out under the constant shaking of off-road driving.

Furthermore, the orientation of the FAW Russian Electric Horn on the bracket is critical. It is positioned to avoid contact with surrounding bodywork. If the horn body touches the frame or grille, the vibration will be grounded out, causing a buzzing noise instead of a clear tone. The bracket design ensures a consistent air gap around the horn, maintaining its acoustic performance and preventing physical damage from abrasion.

Environmental Hardening

The FAW Russian Electric Horn is often mounted behind the front grille, exposing it to direct road spray containing salt, sand, and chemical de-icers. To combat corrosion, the assembly utilizes Hexagon Nut (Part No. CQ34008) and bolts that are treated with a zinc-nickel or dacromet coating. This sacrificial layer protects the steel fasteners from seizing, ensuring that the horn can be easily replaced if necessary.

The electrical connection to the High Pitch Electric Horn Assembly is made via a weather-sealed connector. In the FAW Russian Electric Horn system, this connector features silicone seals to prevent water wicking. A corroded contact increases resistance, dropping the voltage available to the solenoid. Since the sound output of an electric horn is exponentially related to voltage, even a small drop can significantly reduce volume. The sealed design ensures full power delivery in all weather conditions.

Additionally, the internal breaker points of the horn are often tungsten-tipped to resist arcing and pitting. In cold weather, the inrush current can be higher, putting more stress on these contacts. The robust internal design of the FAW Russian Electric Horn ensures a long cycle life, capable of hundreds of thousands of activations without contact welding or failure.

Diagnostics and Tuning

Unlike air horns, the FAW Russian Electric Horn has a tuning screw that adjusts the gap between the contacts. Over time, wear can alter this gap, changing the tone or causing the horn to stop working. While factory units are sealed, some allow for minor adjustment. However, for fleet operators, the most efficient solution to a failing horn is typically replacement. The diagnostic process involves checking for voltage at the connector while the button is pressed. If voltage is present but the horn is silent, the internal solenoid is likely failed.

If the horn sounds weak or raspy, inspect the Electric Horn Bracket for cracks. A cracked bracket changes the resonant frequency of the assembly. Also, ensure the Hexagon Flange Bolt fasteners are tight. A loose horn dissipates energy into the loose joint rather than producing sound.

Replacing the FAW Russian Electric Horn with a genuine FAW part ensures that the current draw matches the vehicle’s fuse rating and wiring gauge. Aftermarket horns may draw excessive current, blowing fuses or melting switches. Sticking to the OEM specification maintains the integrity of the truck’s electrical system and ensures compliance with noise regulations.

Conclusion: The Voice of Urban Safety

The FAW Russian Electric Horn assembly is a compact, vital safety component comprising just 9 parts. Its role in urban and site safety is undeniable, providing the necessary acoustic warning to pedestrians and light vehicles. The robust construction, environmental sealing, and vibration-isolating mount make it uniquely clearer suited for the Russian environment.

For fleet maintenance teams, checking the operation of the FAW Russian Electric Horn should be part of every pre-trip inspection. Ensuring that the horn is loud, securely mounted, and free of debris guarantees that the driver has a reliable means of communication in an emergency. By using genuine parts and proper installation techniques, operators ensure the voice of their fleet remains strong and clear.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.