FAW Russian Steering Transmission System: Engineering 10 Critical Components for Arctic Control Precision in Heavy-Duty Dump Trucks

The FAW Russian Steering Transmission System represents the mechanical interface that translates driver input into directional control for the CA3250P66K24L1TE5Z 6×6 dump truck operating in extreme Siberian conditions. This technical analysis deconstructs the complete steering mechanism into its fundamental serviceable units, revealing how ten precision-engineered components ensure reliable steering response, structural integrity, and operational durability at temperatures reaching -40°C. Our examination focuses on the mechanical linkages, protective systems, and cold-weather adaptations that maintain steering precision in the harsh Russian mining environment.

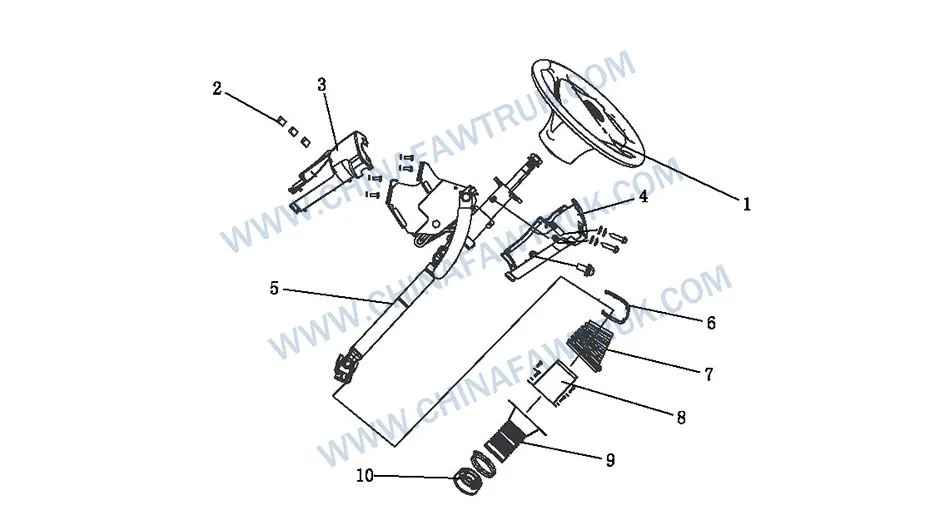

FAW Russian Steering Transmission System

Primary Control Interface: Steering Wheel and Button Assembly

The Steering Wheel and Button Assembly (Part No. 3402010-10W) serves as the primary human-machine interface in the FAW Russian Steering Transmission System. This multifunctional component integrates heated grip technology with control buttons for various vehicle functions. The 10W suffix indicates its winterized specification, featuring specialized elastomers that maintain flexibility at temperatures down to -50°C. The wheel’s magnesium alloy core provides structural integrity while minimizing weight, and the over-molded foam grip contains conductive heating elements that maintain surface temperatures above 15°C even in extreme cold conditions.

Integrated switch modules within the assembly control cruise management, audio systems, and communication functions. These switches are sealed to IP6K9K standards, providing complete protection against dust, high-pressure water jets, and steam cleaning procedures. For the FAW Russian Steering Transmission System, this level of sealing is essential to prevent moisture ingress during temperature fluctuations, which could cause electrical malfunctions in the control circuits. The switches employ gold-plated contacts that ensure reliable electrical connections despite potential condensation formation in Arctic operating conditions.

The assembly’s mounting interface to the steering column utilizes a precision splined connection secured with a high-torque lock nut. This connection must maintain perfect alignment to prevent steering wheel oscillation or vibration at highway speeds. The FAW Russian Steering Transmission System employs a keyed spline design that ensures consistent angular positioning during reassembly, maintaining proper clock-spring alignment for the airbag system and preserving correct switch orientation for ergonomic operation by the driver during extended shifts in mining operations.

Column Protection System: Covers and Retention Components

The steering column is protected by complementary covers including the Front Steering Column Cover (Part No. 3403061-10W) and Rear Steering Column Cover (Part No. 3403062-10W). These ABS plastic components form a complete shroud that conceals mechanical components while preventing accidental contact with moving parts. In the FAW Russian Steering Transmission System, these covers utilize UV-stabilized polymers with anti-static additives that prevent dust accumulation, a critical feature for trucks operating in dusty mining environments where particulate contamination can compromise interior air quality.

Securing the front cover are three Clips – Front Steering Column Cover (Part No. 3403166-50A). These precision-engineered clips provide secure attachment without visible fasteners, maintaining clean interior aesthetics. Manufactured from glass-filled nylon, these clips maintain their spring properties at temperatures as low as -40°C, ensuring they don’t become brittle and fracture during installation or removal in cold conditions. The FAW Russian Steering Transmission System requires these clips to withstand repeated removal cycles during maintenance without loss of retention force, a design consideration that reduces long-term ownership costs.

Completing the lower protection is the Steering Column Lower Cover (Part No. 3403051-50A), which bridges the gap between the column assembly and the instrument panel. This component features flexible living hinges that accommodate the full range of column tilt adjustment without creating unsightly gaps. For the FAW Russian Steering Transmission System, this cover also incorporates cable management features that organize wiring harnesses, preventing interference with column movement while protecting wires from abrasion that could lead to electrical faults during the vehicle’s service life.

Structural Foundation: Column Bracket and Hinge Assembly

The mechanical foundation of the FAW Russian Steering Transmission System is the Steering Column Bracket and Hinge Assembly (Part No. 3403010-76W). This fabricated steel component provides the rigid mounting interface between the steering column and the vehicle cab structure. The 76W designation indicates an enhanced winter specification with additional corrosion protection layers, including zinc-nickel electroplating and a chromate conversion coating that provides exceptional resistance to road salts and de-icing chemicals used extensively in Russian winter road maintenance.

Reinforcing this assembly are two Brackets (Part No. 3403071-50A) that provide additional support at critical stress concentration points. These high-strength steel components feature strategic ribbing that increases stiffness without adding excessive weight. In the FAW Russian Steering Transmission System, these brackets are designed to withstand dynamic loading during off-road operation, where uneven terrain transmits significant impact forces through the steering column to the cab structure, requiring robust support to maintain precise steering geometry.

The hinge mechanism within the assembly incorporates a friction plate system that maintains the selected steering wheel position without gradual sinking. This system utilizes Belleville washers that provide consistent clamping force throughout the adjustment range. For the FAW Russian Steering Transmission System, the hinge is lubricated with low-temperature synthetic grease that maintains consistent viscosity, ensuring smooth adjustment operation even after extended parking periods in extreme cold conditions where conventional lubricants would stiffen and impede adjustment functionality.

Contamination Protection: Dust Boots and Retention Systems

Preventing contamination ingress is critical for the FAW Russian Steering Transmission System, achieved through the Dust Boot (Part No. 3403049-10W). This flexible bellows-style seal protects the upper steering column bearing from dust, moisture, and abrasive particles. Manufactured from thermoplastic elastomer with excellent cold-weather flexibility, this boot maintains its sealing properties across the entire operational temperature range from -50°C to +85°C, a requirement for vehicles operating in Siberian conditions with extreme seasonal temperature variations.

Additional protection is provided by the Steering Column Dust Boot (Part No. 3403067-50A), which seals the lower column interface near the floor pan. This component prevents contaminants from entering through the cab floor area, particularly important for trucks operating on unpaved mining roads where dust concentrations exceed 50mg/m³. The boot’s material formulation includes anti-static additives that prevent dust adhesion, maintaining optical clarity for visual inspection of underlying components during routine maintenance procedures.

Securing these protective elements is the Clamp (Part No. 3403063-10W), a stainless steel band that provides positive retention for flexible components. This clamp features a rolled-edge design that prevents cutting into elastomeric materials, while the locking mechanism employs a positive-engagement screw with nylon insert that resists vibration-induced loosening. In the FAW Russian Steering Transmission System, this component ensures protective boots remain correctly positioned throughout the vehicle’s service life, maintaining the integrity of critical sealing systems that protect precision steering components from environmental contamination.

Arctic Material Science: Cold-Weather Performance Engineering

Every component in the FAW Russian Steering Transmission System is engineered with materials specifically formulated for cryogenic performance. Standard polymers typically become brittle below -20°C, but the materials used here incorporate specialized plasticizers and impact modifiers that maintain ductility down to -50°C. This is particularly critical for components like the Front Steering Column Cover and Rear Steering Column Cover, which must withstand occasional impacts from tools or equipment in the cabin without fracturing during extreme cold conditions.

Metallic components undergo specialized heat treatments that optimize their mechanical properties for low-temperature operation. The Steering Column Bracket and Hinge Assembly receives normalizing and stress-relieving treatments that minimize residual stresses that could lead to brittle fracture under impact loading in cold conditions. For the FAW Russian Steering Transmission System, these metallurgical processes ensure components maintain their designed strength characteristics throughout the operational temperature range, providing consistent performance regardless of environmental conditions.

Corrosion protection extends beyond visible surfaces to include comprehensive coating systems. The Brackets and structural components receive multi-layer protection including phosphate coating for adhesion promotion, electrophoretic deposition for complete coverage including recessed areas, and powder coat finishing for additional mechanical and chemical resistance. This comprehensive approach in the FAW Russian Steering Transmission System combats the highly corrosive environment created by road salts, industrial pollutants, and constant freeze-thaw cycles encountered in Russian mining and transportation operations.

Maintenance Protocols: Service Intervals and Component Inspection

Regular maintenance of the FAW Russian Steering Transmission System begins with inspection of the Dust Boot and Steering Column Dust Boot for signs of tearing, cracking, or permanent deformation. Any compromise in these seals allows contaminants to enter the column mechanism, accelerating wear on bearings and universal joints. Replacement intervals for these components are typically 100,000 km under normal conditions, but should be reduced to 50,000 km for vehicles operating in extremely dusty environments like Russian open-pit mining operations.

The heating element within the Steering Wheel and Button Assembly requires periodic functional testing using a thermal imaging camera or surface temperature probe. Element resistance should measure within ±10% of the specified value when tested at 20°C ambient temperature. For the FAW Russian Steering Transmission System, maintaining functional heating is essential for driver comfort and safety, as a cold, stiff steering wheel reduces tactile feedback and increases driver fatigue during extended operation in Arctic conditions.

All retention components including the Clips – Front Steering Column Cover should be inspected for proper engagement during routine maintenance. These clips are designed for multiple removal and installation cycles, but replacement is recommended if they show signs of deformation or reduced retention force. The Clamp securing protective boots should be checked for proper torque application, as specified in technical documentation. Proper maintenance ensures the FAW Russian Steering Transmission System maintains its designed performance, reliability, and safety throughout the vehicle’s operational life in demanding Russian conditions.

Component Breakdown: Steering Wheel and Steering Transmission Device

| No. |

Part Number |

Part Name |

Qty |

| 1 | 3402010-10W | Steering wheel and button assembly (style drawing) | 1 |

| 2 | 3403166-50A | Clip – front steering column cover | 3 |

| 3 | 3403061-10W | Front steering column cover | 1 |

| 4 | 3403062-10W | Rear steering column cover | 1 |

| 5 | 3403010-76W | Steering column bracket and hinge assembly | 1 |

| 6 | 3403063-10W | Clamp | 1 |

| 7 | 3403049-10W | Dust boot | 1 |

| 8 | 3403051-50A | Steering column lower cover | 1 |

| 9 | 3403067-50A | Steering column dust boot | 1 |

| 10 | 3403071-50A | Bracket | 2 |

Conclusion: The Integrated Control Transmission System

The FAW Russian Steering Transmission System represents a sophisticated integration of ergonomic design, mechanical engineering, and environmental protection. From the heated Steering Wheel and Button Assembly to the robust Steering Column Bracket and Hinge Assembly, each of the ten detailed components contributes to a reliable, precise, and durable control interface. This system provides the tactile feedback and mechanical precision necessary for operators to maneuver heavy vehicles through challenging Arctic conditions with confidence and accuracy, ensuring productive operation in the world’s most demanding environments.

Understanding the complete breakdown of the steering transmission system empowers maintenance teams to perform targeted inspections and preventative replacements. Adherence to the specified part numbers, such as the winterized 3403010-76W assembly and the critical Clips – Front Steering Column Cover (3403166-50A), ensures the FAW Russian Steering Transmission System maintains its designed performance and safety margins throughout the vehicle’s service life. For operators in extreme environments, this system is not merely a collection of components; it is the vital interface that translates driver intention into precise vehicle response, shift after demanding shift in Russia’s most challenging mining and transportation operations.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.