Sistema de transmisión de dirección ruso FAW: Ingeniería 10 Componentes críticos para la precisión del control del Ártico en camiones volquete de servicio pesado

El Sistema de transmisión de dirección ruso FAW representa la interfaz mecánica que traduce la entrada del controlador en control direccional para el CA3250P66K24L1TE5Z 6×6 Camión volquete operando en condiciones extremas en Siberia. Este análisis técnico deconstruye el mecanismo de dirección completo en sus unidades fundamentales de servicio., revela cómo diez componentes diseñados con precisión garantizan una respuesta de dirección confiable, integridad estructural, y durabilidad operativa a temperaturas que alcanzan los -40°C. Nuestro examen se centra en los enlaces mecánicos., sistemas de protección, y adaptaciones al clima frío que mantienen la precisión de la dirección en el duro entorno minero ruso.

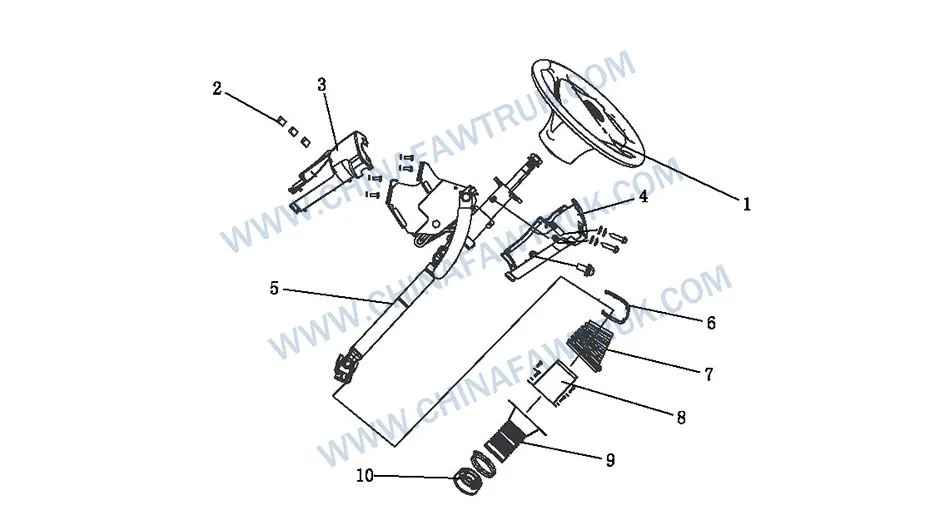

Sistema de transmisión de dirección ruso FAW

Interfaz de control primario: Conjunto de volante y botón

El Conjunto de volante y botón (Número de pieza. 3402010-10W.) Sirve como la principal interfaz hombre-máquina en el Sistema de transmisión de dirección ruso FAW. Este componente multifuncional integra tecnología de puños calefactables con botones de control para diversas funciones del vehículo.. El sufijo de 10 W indica su especificación preparada para el invierno., Con elastómeros especializados que mantienen la flexibilidad a temperaturas de hasta -50 °C.. El núcleo de aleación de magnesio de la rueda proporciona integridad estructural al tiempo que minimiza el peso., y la empuñadura de espuma sobremoldeada contiene elementos calefactores conductores que mantienen la temperatura de la superficie por encima de los 15 °C incluso en condiciones de frío extremo..

Módulos de conmutación integrados en la gestión de crucero del control de montaje, sistemas de audio, y funciones de comunicación. Estos interruptores están sellados según los estándares IP6K9K., proporcionando una protección completa contra el polvo, chorros de agua a alta presión, y procedimientos de limpieza con vapor. Para el Sistema de transmisión de dirección ruso FAW, Este nivel de sellado es esencial para evitar la entrada de humedad durante las fluctuaciones de temperatura., lo que podría causar fallos eléctricos en los circuitos de control.. Los interruptores emplean contactos chapados en oro que garantizan conexiones eléctricas confiables a pesar de la posible formación de condensación en condiciones de funcionamiento en el Ártico..

La interfaz de montaje del conjunto en la columna de dirección utiliza una conexión estriada de precisión asegurada con una contratuerca de alto torque.. Esta conexión debe mantener una alineación perfecta para evitar la oscilación o vibración del volante a velocidades de autopista.. El Sistema de transmisión de dirección ruso FAW Emplea un diseño estriado con llave que garantiza un posicionamiento angular consistente durante el reensamblaje., Mantener la alineación adecuada del resorte del reloj para el sistema de bolsas de aire y preservar la orientación correcta del interruptor para una operación ergonómica por parte del conductor durante turnos prolongados en operaciones mineras..

Sistema de protección de columnas: Cubiertas y componentes de retención

La columna de dirección está protegida por cubiertas complementarias que incluyen la Cubierta de la columna de dirección delantera (Número de pieza. 3403061-10W.) y Cubierta de la columna de dirección trasera (Número de pieza. 3403062-10W.). Estos componentes de plástico ABS forman una cubierta completa que oculta los componentes mecánicos y evita el contacto accidental con las piezas móviles.. En el Sistema de transmisión de dirección ruso FAW, Estas cubiertas utilizan polímeros estabilizados contra los rayos UV con aditivos antiestáticos que evitan la acumulación de polvo., una característica crítica para camiones que operan en ambientes mineros polvorientos donde la contaminación por partículas puede comprometer la calidad del aire interior.

Para asegurar la cubierta frontal hay tres Clips – Cubierta de la columna de dirección delantera (Número de pieza. 3403166-50A). Estos clips diseñados con precisión proporcionan una fijación segura sin sujetadores visibles., mantener una estética interior limpia. Fabricado con nailon relleno de vidrio., Estos clips mantienen sus propiedades elásticas a temperaturas tan bajas como -40°C., asegurando que no se vuelvan quebradizos y se rompan durante la instalación o extracción en condiciones de frío. El Sistema de transmisión de dirección ruso FAW Requiere que estos clips soporten ciclos repetidos de extracción durante el mantenimiento sin pérdida de fuerza de retención., una consideración de diseño que reduce los costos de propiedad a largo plazo.

Completando la protección inferior está el Cubierta inferior de la columna de dirección (Número de pieza. 3403051-50A), que cierra la brecha entre el conjunto de la columna y el panel de instrumentos. Este componente cuenta con bisagras vivas flexibles que se adaptan a toda la gama de ajustes de inclinación de la columna sin crear espacios antiestéticos.. Para el Sistema de transmisión de dirección ruso FAW, Esta cubierta también incorpora funciones de gestión de cables que organizan los mazos de cables., evitando interferencias con el movimiento de la columna y al mismo tiempo protegiendo los cables de la abrasión que podría provocar fallas eléctricas durante la vida útil del vehículo..

Cimentación estructural: Conjunto de soporte de columna y bisagra

La base mecánica del Sistema de transmisión de dirección ruso FAW es el Conjunto de soporte y bisagra de la columna de dirección (Número de pieza. 3403010-76W.). Este componente de acero fabricado proporciona una interfaz de montaje rígida entre la columna de dirección y la estructura de la cabina del vehículo.. La designación 76W indica una especificación de invierno mejorada con capas adicionales de protección contra la corrosión., incluyendo galvanoplastia de zinc-níquel y un recubrimiento de conversión de cromato que proporciona una resistencia excepcional a las sales de las carreteras y a los productos químicos descongelantes utilizados ampliamente en el mantenimiento de carreteras en invierno en Rusia..

Reforzando este conjunto hay dos Soportes (Número de pieza. 3403071-50A) que proporcionan soporte adicional en puntos críticos de concentración de tensiones. Estos componentes de acero de alta resistencia cuentan con nervaduras estratégicas que aumentan la rigidez sin agregar peso excesivo.. En el Sistema de transmisión de dirección ruso FAW, Estos soportes están diseñados para soportar cargas dinámicas durante la operación todoterreno., donde el terreno irregular transmite fuerzas de impacto significativas a través de la columna de dirección a la estructura de la cabina, Requiere un soporte robusto para mantener una geometría de dirección precisa..

El mecanismo de bisagra dentro del conjunto incorpora un sistema de placa de fricción que mantiene la posición seleccionada del volante sin hundirse gradualmente.. Este sistema utiliza arandelas Belleville que proporcionan una fuerza de sujeción constante en todo el rango de ajuste.. Para el Sistema de transmisión de dirección ruso FAW, la bisagra está lubricada con grasa sintética de baja temperatura que mantiene una viscosidad constante, Garantizar una operación de ajuste suave incluso después de períodos prolongados de estacionamiento en condiciones de frío extremo donde los lubricantes convencionales se endurecerían e impedirían la funcionalidad de ajuste..

Protección contra la contaminación: Botas antipolvo y sistemas de retención

Prevenir el ingreso de contaminación es fundamental para el Sistema de transmisión de dirección ruso FAW, logrado a través de la Bota antipolvo (Número de pieza. 3403049-10W.). Este sello flexible tipo fuelle protege el cojinete superior de la columna de dirección del polvo., humedad, y partículas abrasivas. Fabricado con elastómero termoplástico con excelente flexibilidad en climas fríos., esta funda mantiene sus propiedades de sellado en todo el rango de temperatura operativa de -50 °C a +85 °C, un requisito para los vehículos que operan en condiciones siberianas con variaciones extremas de temperatura estacional.

La protección adicional la proporciona el Guardapolvo de la columna de dirección (Número de pieza. 3403067-50A), que sella la interfaz de la columna inferior cerca del piso. Este componente evita que entren contaminantes a través del área del piso de la cabina., particularmente importante para camiones que operan en caminos mineros sin pavimentar donde las concentraciones de polvo superan los 50 mg/m³. La formulación del material de la bota incluye aditivos antiestáticos que evitan la adhesión del polvo., Mantener la claridad óptica para la inspección visual de los componentes subyacentes durante los procedimientos de mantenimiento de rutina..

Asegurar estos elementos de protección es la Abrazadera (Número de pieza. 3403063-10W.), una banda de acero inoxidable que proporciona retención positiva para componentes flexibles. Esta abrazadera presenta un diseño de borde enrollado que evita cortar materiales elastoméricos., mientras que el mecanismo de bloqueo emplea un tornillo de acoplamiento positivo con inserto de nailon que resiste el aflojamiento inducido por la vibración.. En el Sistema de transmisión de dirección ruso FAW, Este componente garantiza que las botas protectoras permanezcan correctamente colocadas durante toda la vida útil del vehículo., Mantener la integridad de los sistemas de sellado críticos que protegen los componentes de dirección de precisión de la contaminación ambiental..

Ciencia de los materiales árticos: Ingeniería de rendimiento en climas fríos

Cada componente en el Sistema de transmisión de dirección ruso FAW está diseñado con materiales específicamente formulados para rendimiento criogénico. Los polímeros estándar suelen volverse quebradizos por debajo de -20°C, pero los materiales utilizados aquí incorporan plastificantes especializados y modificadores de impacto que mantienen la ductilidad hasta -50°C.. Esto es particularmente crítico para componentes como el Cubierta de la columna de dirección delantera y Cubierta de la columna de dirección trasera, que debe resistir impactos ocasionales de herramientas o equipos en la cabina sin fracturarse durante condiciones de frío extremo.

Los componentes metálicos se someten a tratamientos térmicos especializados que optimizan sus propiedades mecánicas para el funcionamiento a baja temperatura.. El Conjunto de soporte y bisagra de la columna de dirección recibe tratamientos de normalización y alivio de tensiones que minimizan las tensiones residuales que podrían provocar una fractura frágil bajo cargas de impacto en condiciones de frío.. Para el Sistema de transmisión de dirección ruso FAW, Estos procesos metalúrgicos garantizan que los componentes mantengan sus características de resistencia diseñadas en todo el rango de temperatura operativa., proporcionando un rendimiento constante independientemente de las condiciones ambientales.

La protección contra la corrosión se extiende más allá de las superficies visibles e incluye sistemas integrales de recubrimiento. El Soportes y los componentes estructurales reciben protección multicapa que incluye un recubrimiento de fosfato para promover la adhesión, Deposición electroforética para una cobertura completa, incluidas las áreas empotradas., y acabado con pintura en polvo para mayor resistencia mecánica y química. Este enfoque integral en el Sistema de transmisión de dirección ruso FAW combate el ambiente altamente corrosivo creado por las sales de la carretera, contaminantes industriales, y los constantes ciclos de congelación y descongelación que se encuentran en las operaciones mineras y de transporte rusas..

Protocolos de mantenimiento: Intervalos de servicio e inspección de componentes

Mantenimiento regular de la Sistema de transmisión de dirección ruso FAW comienza con la inspección del Bota antipolvo y Guardapolvo de la columna de dirección para signos de desgarro, agrietamiento, o deformación permanente. Cualquier compromiso en estos sellos permite que los contaminantes ingresen al mecanismo de la columna., Acelerar el desgaste de rodamientos y juntas universales.. Los intervalos de reemplazo para estos componentes generalmente son 100,000 km en condiciones normales, pero debería reducirse a 50,000 km para vehículos que operan en ambientes extremadamente polvorientos como las operaciones mineras a cielo abierto rusas.

El elemento calefactor dentro del Conjunto de volante y botón Requiere pruebas funcionales periódicas utilizando una cámara termográfica o una sonda de temperatura de superficie.. La resistencia del elemento debe medirse dentro de ±10 % del valor especificado cuando se prueba a una temperatura ambiente de 20 °C.. Para el Sistema de transmisión de dirección ruso FAW, Mantener la calefacción funcional es esencial para la comodidad y seguridad del conductor., como un resfriado, El volante rígido reduce la retroalimentación táctil y aumenta la fatiga del conductor durante la operación prolongada en condiciones árticas..

Todos los componentes de retención, incluido el Clips – Cubierta de la columna de dirección delantera Se debe inspeccionar el acoplamiento adecuado durante el mantenimiento de rutina.. Estos clips están diseñados para múltiples ciclos de extracción e instalación., pero se recomienda reemplazarlos si muestran signos de deformación o fuerza de retención reducida.. El Abrazadera Se debe verificar que las botas protectoras de seguridad se apliquen el torque adecuado., como se especifica en la documentación técnica. Un mantenimiento adecuado garantiza la Sistema de transmisión de dirección ruso FAW mantiene su rendimiento diseñado, fiabilidad, y seguridad durante toda la vida operativa del vehículo en las exigentes condiciones rusas.

Desglose de componentes: Dispositivo de transmisión del volante y de la dirección

| No. |

Número de pieza |

Nombre de la pieza |

Cantidad |

| 1 | 3402010-10W. | Conjunto de volante y botones. (dibujo de estilo) | 1 |

| 2 | 3403166-50A | Acortar – cubierta de la columna de dirección delantera | 3 |

| 3 | 3403061-10W. | Cubierta de la columna de dirección delantera | 1 |

| 4 | 3403062-10W. | Cubierta de la columna de dirección trasera | 1 |

| 5 | 3403010-76W. | Conjunto de soporte y bisagra de la columna de dirección | 1 |

| 6 | 3403063-10W. | Abrazadera | 1 |

| 7 | 3403049-10W. | bota antipolvo | 1 |

| 8 | 3403051-50A | Cubierta inferior de la columna de dirección | 1 |

| 9 | 3403067-50A | Guardapolvo de la columna de dirección | 1 |

| 10 | 3403071-50A | Soporte | 2 |

Conclusión: El sistema de transmisión de control integrado

El Sistema de transmisión de dirección ruso FAW representa una integración sofisticada de diseño ergonómico, Ingeniería Mecánica, y protección del medio ambiente. De lo calentado Conjunto de volante y botón a lo robusto Conjunto de soporte y bisagra de la columna de dirección, Cada uno de los diez componentes detallados contribuye a una fiabilidad., preciso, y interfaz de control duradera. Este sistema proporciona la retroalimentación táctil y la precisión mecánica necesarias para que los operadores maniobren vehículos pesados en condiciones desafiantes del Ártico con confianza y precisión., Garantizar un funcionamiento productivo en los entornos más exigentes del mundo..

Comprender la avería completa del sistema de transmisión de dirección permite a los equipos de mantenimiento realizar inspecciones específicas y reemplazos preventivos.. Cumplimiento de los números de pieza especificados., como el conjunto 3403010-76W preparado para el invierno y el crítico Clips – Cubierta de la columna de dirección delantera (3403166-50A), asegura la Sistema de transmisión de dirección ruso FAW mantiene sus márgenes de rendimiento y seguridad diseñados durante toda la vida útil del vehículo. Para operadores en ambientes extremos, Este sistema no es simplemente una colección de componentes.; Es la interfaz vital que traduce la intención del conductor en una respuesta precisa del vehículo., Cambio tras cambio exigente en las operaciones de minería y transporte más desafiantes de Rusia..

Embalaje y Logística

piezas FAW, incluido el conjunto del bloque de cilindros, Se empaquetan con cuidado para garantizar una entrega segura.. Cada componente está asegurado con materiales protectores para evitar daños durante el transporte.. La red logística garantiza envíos puntuales en todo el mundo., apoyando operaciones de mantenimiento eficientes. A continuación se muestra una imagen que ilustra el embalaje estándar de las piezas de camiones FAW., mostrando la atención al detalle en el manejo y almacenamiento.

Este enfoque de embalaje minimiza el riesgo de corrosión o daños por impacto., asegurando que piezas como el conjunto de bloque de cilindros FAW lleguen en perfectas condiciones. Los clientes pueden confiar en la logística de FAW para obtener calidad y confiabilidad constantes.