FAW Russian Wheel And Tire: Optimizing 15 Cold-Resistant Components for Off-Road Stability

The FAW Russian Wheel And Tire assembly is the final and most visible link in the power delivery chain of the CA3250P66K24L1TE5Z dump truck. Designed to withstand the immense static load of the payload and the high dynamic forces of Siberian terrain, this assembly features specialized cold-weather rubber compounds and a heavy-duty demountable rim structure. The integrity of the FAW Russian Wheel And Tire is paramount, directly influencing traction, fuel efficiency, and vehicle safety at temperatures reaching -50°C. This guide analyzes the tire specification, the robust rim components, and the crucial balancing technology that ensures a smooth ride.

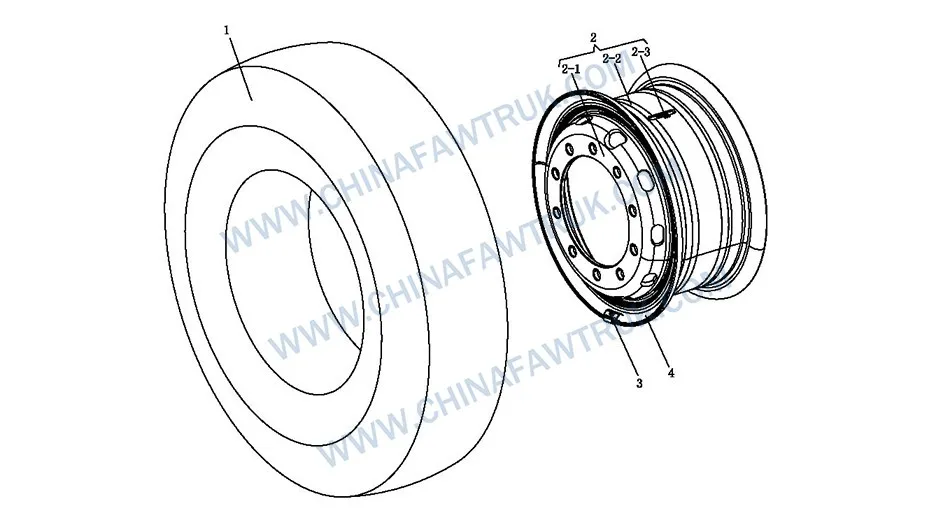

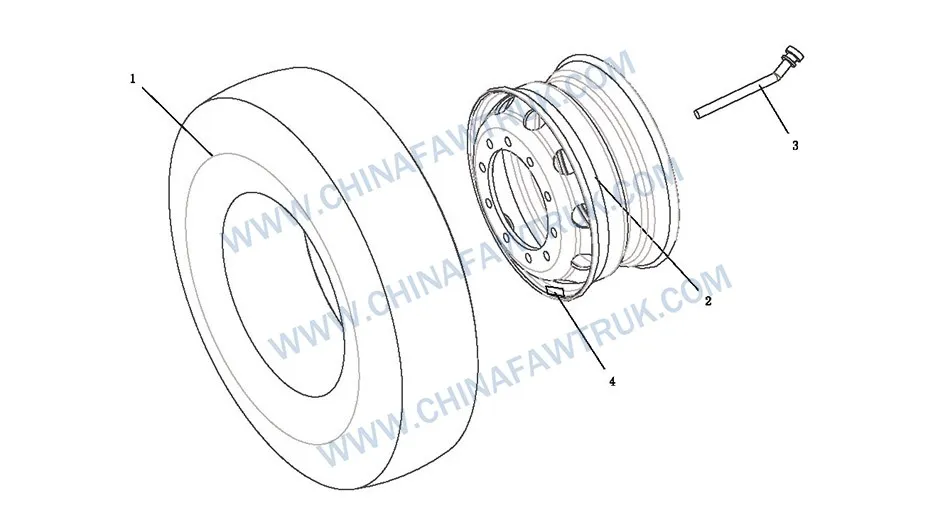

FAW Russian Wheel And Tire

Tire Specification and Cold-Weather Compounds

The operational capability of the FAW Russian Wheel And Tire starts with the specific tire selected: the **12.00R20 20-ply Tire** (Part No. 3106010-55R). This rating signifies an exceptionally robust construction capable of handling the heavy payload capacity of the dump truck. The 20-ply rating ensures the sidewalls resist punctures and cuts common in mining environments, while the radial construction (R) provides superior heat dissipation and longer lifespan compared to bias-ply tires. This heavy-duty tire is specifically tuned for the FAW Russian Wheel And Tire assembly.

The “55R” suffix associated with the **Tire/Wheel Assembly** (Part No. 3101010-55R) is crucial for the Russian application, indicating a rubber compound optimized for low temperatures. Standard tire compounds harden significantly in the cold, losing traction and becoming brittle, leading to chipping and cracking. The rubber used in the FAW Russian Wheel And Tire retains flexibility and grip even in the deepest freeze, ensuring the truck maintains steering control and braking effectiveness on ice and packed snow.

The size, 12.00R20, provides the necessary vertical height for ground clearance when traversing rough off-road terrain. The large footprint of the tire, when correctly inflated, distributes the massive vehicle weight over a wide area, reducing unit pressure on the ground. This is vital for navigating soft ground conditions during the spring thaw, where a smaller tire would easily sink. The tread pattern of the FAW Russian Wheel And Tire typically features deep, aggressive lugs to maximize traction in mud and snow.

Correct tire pressure is paramount for the FAW Russian Wheel And Tire performance. Under-inflation in cold weather increases rolling resistance and heat buildup, which can be catastrophic for a heavily loaded tire. Conversely, over-inflation reduces the contact patch, compromising traction on slippery surfaces. Fleet managers must adhere strictly to the recommended cold inflation pressures to maintain the safety and efficiency of the FAW Russian Wheel And Tire assembly.

Rim Architecture and Security

The wheel assembly is a multi-piece unit designed for heavy-duty tube tires. It consists of the **8.5-20 Wheel Rim & Rim Assembly** (Part No. 3101015-93W), which is further broken down into the **Rim Body – 8.5-20** (Part No. 3101021-93W) and the **Wheel Rim – 8.5-20** (Part No. 3101036-93W). This demountable rim design allows for easier installation and repair of the massive 12.00R20 tire, especially in remote field conditions where specialized tire mounting equipment may be unavailable. The robustness of the FAW Russian Wheel And Tire rim components is crucial.

Securing the rim pieces is the **Elastic Retaining Ring – 8.5-20 Wheel Rim** (Part No. 3101027-174). This ring locks the tire’s bead in place against the rim body once pressure is applied. The structural integrity of this ring is non-negotiable; a failed ring can lead to explosive tire decompression. Furthermore, the **8.5-20 Rim Lock** (Part No. 3101016-174) ensures that the various rim components are held tightly together. These retention systems are subjected to high shear stress from the tire bead under load.

The FAW Russian Wheel And Tire assembly relies on these components remaining perfectly concentric. Any deformation in the rim body or the wheel rim will create vibration and uneven tire wear. The heavy steel gauge used in the rim components provides the necessary rigidity to prevent damage during axle articulation and side-loading against curbs or rocks. The fasteners and locking components are all plated to resist rust, which is vital for the long-term structural integrity of the FAW Russian Wheel And Tire.

Dynamic Balancing and Vibration Control

Maintaining dynamic balance is essential for the longevity of the FAW Russian Wheel And Tire. Unbalanced assemblies transmit severe vibrations into the driveline, accelerating wear on steering components, suspension bushings, and differential bearings. To counteract slight mass variations in the tire and rim casting, the assembly requires **8.5 Rim Balance Mass** components (Part No. 3101050-174 through 3101075-174, plus 3101080-174). These are small lead or non-lead masses attached to the rim lip or inner surface.

The inclusion of various weights and sizes of balance masses highlights the precision required for heavy-duty truck wheels. Due to the size of the FAW Russian Wheel And Tire and the speed at which the truck travels, even a few ounces of imbalance can create destructive forces. The various part numbers of the **8.5 Rim Balance Mass** components allow mechanics to fine-tune the balance to ensure smooth operation across the vehicle’s speed range, reducing driver fatigue and preventing premature wear.

In cold weather, achieving and maintaining dynamic balance for the FAW Russian Wheel And Tire can be challenging. Packed snow and ice adhering to the inner rim surface can throw the balance off instantly. Fleet maintenance protocols often include scraping the rims clean of ice and snow before checking the tire balance. The precision balancing achieved with the **8.5 Rim Balance Mass** components is an investment in the entire vehicle’s structural health.

Maintenance and Cold-Weather Service

Serviceability is key for the FAW Russian Wheel And Tire. The multi-piece rim design is intended to allow for field repair, but it requires strict adherence to safety protocols during disassembly and assembly. Incorrect seating of the **Elastic Retaining Ring** or over-inflation during seating can lead to explosive rim failure. Mechanics must use a safety cage and precise pressure regulation when working with the FAW Russian Wheel And Tire assembly.

Inspection for fatigue cracking in the **Rim Body – 8.5-20** (Part No. 3101021-93W) and **Wheel Rim – 8.5-20** (Part No. 3101036-93W) is mandatory. Heavy impacts from road hazards can stress the rim metal, leading to cracks that compromise bead seating. Any crack discovered in a component of the FAW Russian Wheel And Tire assembly renders the entire wheel unsafe and requires immediate replacement.

When replacing a damaged **FAW Russian Wheel And Tire** assembly, it is vital to ensure that the replacement tire features the correct cold-weather compound and ply rating (20-ply). Using an inferior tire sacrifices safety and durability for a temporary cost saving. The **8.5-20 Rim Lock** (Part No. 3101016-174) should be inspected for deformation or wear every time the tire is removed.

The reliability of the FAW Russian Wheel And Tire system hinges on the condition of all its components, from the rubber to the **Rim Body – 8.5-20**. Utilizing genuine FAW parts ensures that the metallurgical and design specifications—specifically the cold-weather grades—are met, preserving the vehicle’s safe and predictable handling in the challenging Russian operational environment.

Component Breakdown: Wheel and Tire Assembly

| No. |

Part Number |

Part Name |

Qty |

| – | 3101010-55R | Wheel and Tire Assembly | 1 |

| 1 | 3106010-55R | 12.00R20 20-ply Tire | 1 |

| 2 | 3101015-93W | 8.5-20 Wheel Rim & Rim Assembly | 1 |

| 3 | 3101050-174 | 8.5 Rim Balance Mass (Various Weights) | As req |

| 4 | 3101027-174 | Elastic Retaining Ring – 8.5-20 Wheel Rim | 1 |

| 2-1 | 3101036-93W | Wheel Rim – 8.5-20 | 1 |

| 2-2 | 3101021-93W | Rim Body – 8.5-20 | 1 |

| 2-3 | 3101016-174 | 8.5-20 Rim Lock | 1 |

| – | 3101055-174 | 8.5 Rim Balance Mass (Various Weights) | As req |

| – | 3101060-174 | 8.5 Rim Balance Mass (Various Weights) | As req |

| – | 3101065-174 | 8.5 Rim Balance Mass (Various Weights) | As req |

| – | 3101070-174 | 8.5 Rim Balance Mass (Various Weights) | As req |

| – | 3101075-174 | 8.5 Rim Balance Mass (Various Weights) | As req |

Conclusion: The Contact Patch for Arctic Dominance

The FAW Russian Wheel And Tire assembly is the definitive component that translates the truck’s engine power into viable traction on the harsh Siberian terrain. By combining a low-temperature rubber compound with a rugged, multi-piece rim design, FAW ensures maximum durability and safe operation. The integrity of the **Wheel Rim – 8.5-20** (Part No. 3101036-93W) and the security provided by the **Elastic Retaining Ring** (Part No. 3101027-174) are non-negotiable safety factors for the dump truck.

For fleet managers, maintenance of the FAW Russian Wheel And Tire requires strict adherence to pressure and balancing protocols. Ensuring that the **Rim Body – 8.5-20** (Part No. 3101021-93W) is free of damage and the **8.5-20 Rim Lock** (Part No. 3101016-174) is correctly seated is vital. Utilizing genuine FAW parts for the FAW Russian Wheel And Tire assembly guarantees continued operational safety and efficiency in the world’s most challenging cold-weather environment.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.