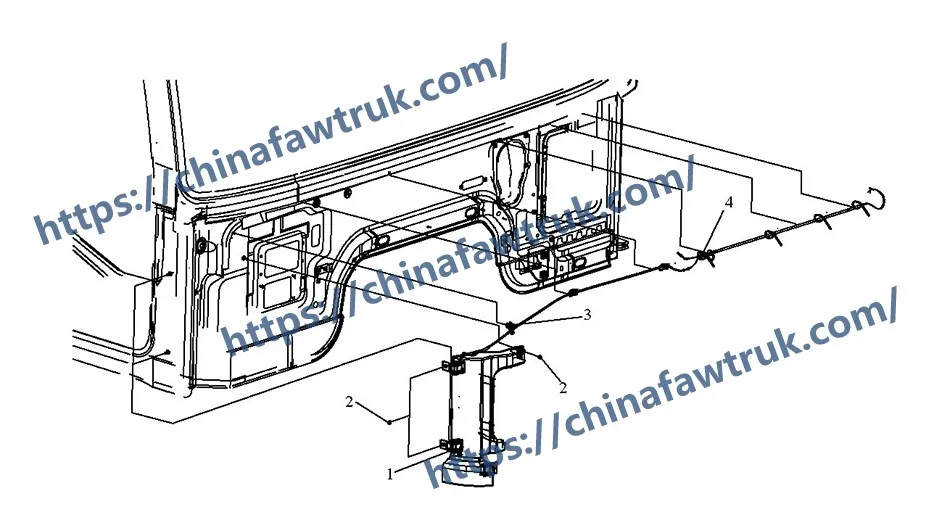

This is a comprehensive technical guide to the FAW J6P Scrubber assembly for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This deconstruction analyzes the 4 primary component types, detailing the integrated pump/reservoir unit, the mounting hardware, and the necessary hose routing security components.

The FAW J6P Scrubber system is a fundamental active safety feature. Its role is to quickly restore the driver’s clear visual field by spraying cleaning fluid onto the windscreen, often under conditions where the glass is heavily coated in mud or grit. The system is designed to provide high-volume fluid delivery and maintain functionality in extreme heat and cold. The central component is the ‘Scrubber assy’ (Comp 1), which integrates both the fluid reservoir and the electric pump motor into a single, compact unit.

This deconstruction will analyze the mechanical retention system (Comp 2) that anchors the heavy, fluid-filled reservoir to the chassis, as well as the specialized hose and wiring routing components (Comp 3, 4) essential for preventing wear. Maintaining the integrity of the FAW J6P Scrubber is paramount for safety, as a failure during adverse weather conditions can suddenly blind the driver. The reliability of the FAW J6P Scrubber is critical for legal compliance and safe operation of the dump truck.

The core function of the FAW J6P Scrubber relies on the seamless integration of fluid storage and pressurized delivery to the windshield nozzles (not listed, but implied).

1. Component: ‘Scrubber assy’ (5207010BA01) – Qty 1

This (Comp 1) is the entire functional mechanism. The Integrated Reservoir Logic is paramount: this assembly contains the fluid tank, the submersible electric pump, and the fluid level sensor. The pump motor must be robust enough to handle the 24V supply and generate sufficient fluid pressure to spray fluid across the wide area of the truck’s windshield. This is the foundation of the FAW J6P Scrubber system.

The System Design Logic requires the pump to be positioned below the fluid level (often inside the tank itself) to ensure continuous operation, even when the fluid level is low. A failure in the pump or the reservoir neck seal will lead to fluid leakage and a non-functional FAW J6P Scrubber. Given the corrosive nature of some washer fluids, the materials used for this reservoir must be highly durable polymer plastic.

This group of hardware provides the necessary rigidity and security to anchor the fluid-filled FAW J6P Scrubber reservoir to the cab or chassis structure.

1. Component: ‘Hex flange lock nut’ (CQ32606) – Qty 3

This (Comp 2) is the primary locking nut. The Anti-Vibration Logic is crucial: this flange nut contains a mechanical feature (a lock flange or insert) that prevents it from vibrating loose. Since the reservoir is a heavy component subject to engine and road vibration, this locking nut is critical for maintaining the structural integrity of the FAW J6P Scrubber mounting.

2. Component: ‘Tie strap clamp II’ (3724012-A01) – Qty 3

This (Comp 3) is a specialized clamp designed for securing the wiring harness and fluid lines near the reservoir. The Routing Security Logic ensures that the electrical wires and the fluid hoses leading from the FAW J6P Scrubber are held firmly in place, preventing them from chafing against sharp metal edges on the chassis.

3. Component: ‘Plastic strap’ (T67414646) – Qty 4

This (Comp 4) is a heavy-duty cable tie. Four of these are used for secondary securement, further anchoring the hoses and harness in high-motion areas away from the immediate mounting point of the FAW J6P Scrubber.

This group addresses the longevity and resilience of the FAW J6P Scrubber system against the harsh operating environment of a heavy-duty dump truck.

1. Component: Environmental Sealing

The motor and tank assembly of the FAW J6P Scrubber are sealed against moisture and dust, which are prevalent on job sites. The material of the reservoir is designed to withstand extreme temperature cycling without cracking, ensuring reliability when the fluid is frozen or exposed to intense engine bay heat. This is central to the operational readiness of the FAW J6P Scrubber.

2. Component: Maintenance and Inspection

Proper serviceability of the FAW J6P Scrubber requires periodic inspection. Technicians must check the security of the mounting lock nuts (Comp 2) and the integrity of the hoses and electrical harness, paying close attention to the tie strap clamp locations (Comp 3, 4). Any sign of fluid leakage or wire chafing compromises the system and must be corrected immediately. The continued function of the FAW J6P Scrubber is essential for maintaining the driver’s critical visual field.

The following table provides the complete, detailed breakdown of all 4 component types in the FAW J6P Scrubber assembly for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This list is essential for ordering spare parts and performing a complete service of the FAW J6P Scrubber.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 5207010BA01 | Scrubber assy | 1 |

| 2 | CQ32606 | Hex flange lock nut | 3 |

| 3 | 3724012-A01 | Tie strap clamp II | 3 |

| 4 | T67414646 | Plastic strap | 4 |

The specifications for the FAW J6P Scrubber are defined by its function as a high-torque, electrically actuated system critical for maintaining driver visibility and safety.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | FAW J6P Scrubber |

| Primary Logic | Electric motor-driven pressurized fluid delivery for windshield cleaning |

| Core Component P/N | 5207010BA01 (Integrated reservoir and pump) |

| Mounting Security | Hex flange lock nut (CQ32606) |

| Hose & Wiring Retention | Tie strap clamp II (3724012-A01) and Plastic strap (T67414646) |

| Total Component Types | 4 |

| Associated System | Cab Exterior / Safety Equipment. The FAW J6P Scrubber ensures continuous visibility. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.