Welcome to this critical technical guide on the FAW Lower Right Centre Shaft Assembly Of The Sub-Box. This is a complete, load-bearing gear and shaft set for the auxiliary “sub-box” (or range box) of the transmission, designed for the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor.

The FAW Lower Right Centre Shaft Assembly Of The Sub-Box (Part No. 1701515FA0L) is the “counter-shaft” for the transmission’s High/Low range selector. In the heavy-duty twin-countershaft design of this gearbox, this shaft is one of two (a matched “upper” and “lower” set) that splits the engine’s torque, providing immense durability.

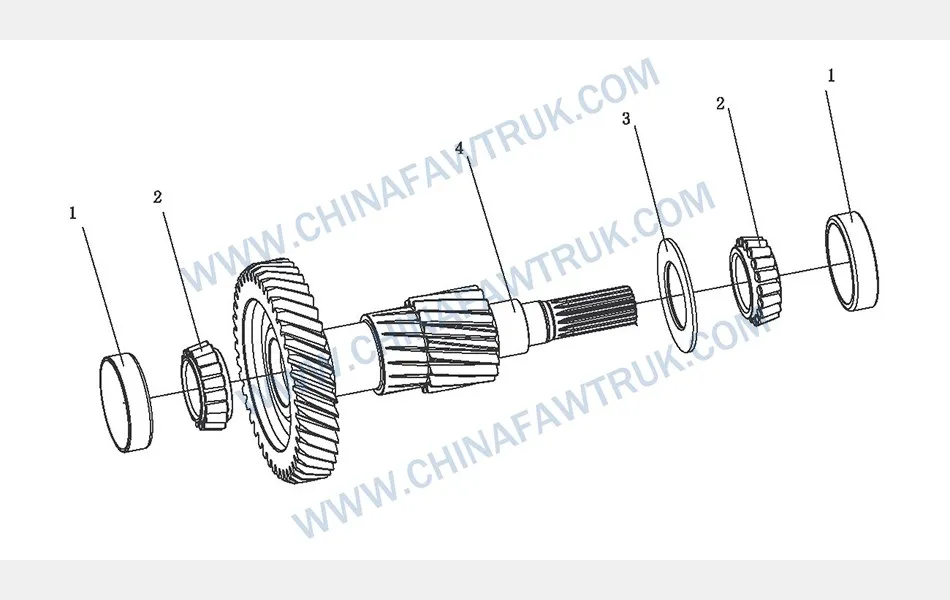

This in-depth guide is an essential resource for professional transmission technicians and parts specialists. We will deconstruct the entire FAW Lower Right Centre Shaft Assembly Of The Sub-Box into its 4 serviceable components, including the main ‘Welded countershaft assembly’, its precision ‘Tapered roller bearings’, and the critical ‘Locating washer’ for setting preload. The integrity of the FAW Lower Right Centre Shaft Assembly Of The Sub-Box is paramount.

The heart of the FAW Lower Right Centre Shaft Assembly Of The Sub-Box is the ‘Welded countershaft assembly-sub box’ (1701515FA0L). This is the main shaft and gear cluster for the auxiliary transmission. This transmission uses a **twin-countershaft** (or “twin-shaft”) sub-box design. This means the load from the main box is split 50/50 between two shafts: this FAW Lower Right Centre Shaft Assembly Of The Sub-Box (the “lower right”) and its “left upper” twin.

This “torque-splitting” design is the hallmark of a heavy-duty transmission. It allows the gearbox to handle the immense torque of a diesel engine using more compact components, as the load on each gear tooth is effectively halved. The “Welded assembly” designation is critical: it means the drive gears for the high/low range are permanently friction-welded to the shaft, creating a single, non-serviceable component of incredible strength. This FAW Lower Right Centre Shaft Assembly Of The Sub-Box is forged from high-manganese steel and case-hardened. A failure of a gear tooth requires the replacement of the entire FAW Lower Right Centre Shaft Assembly Of The Sub-Box.

Each FAW Lower Right Centre Shaft Assembly Of The Sub-Box is supported at its front and rear by a heavy-duty tapered roller bearing. The parts list correctly breaks this bearing (Type 33109) into its two serviceable components:

The quantities of 2 each are for *this specific shaft* (one for the front, one for the rear). The *total* for the entire sub-box would be double this, as seen in the “Left Upper” shaft assembly.

Tapered roller bearings are essential for this application. The helical (angled) gear teeth on the FAW Lower Right Centre Shaft Assembly Of The Sub-Box create immense **axial load** (thrust, or a constant push/pull force) in addition to the **radial load** (the separating force). A standard ball bearing would be quickly destroyed by this axial thrust. Tapered bearings are specifically engineered to handle both forces at once, which is critical for the long-term survival of the FAW Lower Right Centre Shaft Assembly Of The Sub-Box.

The final component of the FAW Lower Right Centre Shaft Assembly Of The Sub-Box is the ‘Locating washer’ (1701518-A0L). The parts list shows a quantity of one, as this specific shaft (the “lower right”) is the one that is “shimmed” to set the preload for the entire twin-shaft assembly. This is not a simple washer; it is a **precision shim**.

This shim’s “logic” is to set the **bearing preload**. This is the single most critical step in a transmission rebuild. Tapered roller bearings cannot be simply installed; they must be “squeezed” together with a precise, pre-calculated amount of force.

* **If the preload is too loose** (shim is too thin), the FAW Lower Right Centre Shaft Assembly Of The Sub-Box will have “end-play,” allowing it to move back and forth. This misalignment causes the helical gear teeth to mesh improperly, leading to a loud, high-pitched “whine,” vibration, and eventual gear tooth failure.

* **If the preload is too tight** (shim is too thick), the bearings are “crushed” together and have no running clearance. This creates immense friction, which overheats, “blues,” and seizes the bearings, destroying the FAW Lower Right Centre Shaft Assembly Of The Sub-Box.

During assembly, a technician must install the shaft, measure the end-play with a dial indicator, and then select a ‘Locating washer’ of the *exact* required thickness from a “selective fit” set (all under the 1701518 part number family). This ensures the FAW Lower Right Centre Shaft Assembly Of The Sub-Box spins freely with zero end-play, guaranteeing a quiet and long-lasting repair.

A failure within the FAW Lower Right Centre Shaft Assembly Of The Sub-Box is a major internal transmission fault. The primary cause is almost always lubrication failure (low or contaminated oil) or an incorrect preload setting during a previous repair.

The main symptom of a failing FAW Lower Right Centre Shaft Assembly Of The Sub-Box bearing is a loud, constant **whining or growling noise** that is tied to vehicle speed, not engine RPM. The noise will be present in all gears (1-12) and will change in pitch only as the truck speeds up or slows down. This is because the auxiliary sub-box is “downstream” of the main box, and its shafts are always spinning in relation to the driveshaft speed.

A secondary, critical failure mode in a twin-countershaft design is **gear timing**. The two shafts (this FAW Lower Right Centre Shaft Assembly Of The Sub-Box and its twin) must be “timed” so their helical gear teeth engage the main shaft at the exact same instant. If one shaft is “off” by a single tooth, the entire torque load will be placed on one shaft instead of being split 50/50. This will rapidly destroy the overloaded FAW Lower Right Centre Shaft Assembly Of The Sub-Box, stripping its gear teeth.

The following table provides the complete, detailed breakdown of all 4 components identified in the ‘Sub-Box Lower Right Centre Shaft Assembly’ diagram for the FAW CA4251P66K24T1A3E5 tractor. This FAW Lower Right Centre Shaft Assembly Of The Sub-Box is one of two matching sets in the auxiliary box.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 33109-1 | Outer ring-tapered roller bearing | 2 |

| 2 | 33109-2 | Inner ring-tapered roller bearing | 2 |

| 3 | 1701518-A0L | Locating washer | 1 |

| 4 | 1701515FA0L | Welded countershaft assembly-sub box | 1 |

The specifications for the FAW Lower Right Centre Shaft Assembly Of The Sub-Box are defined by its function as one half of a high-torque, twin-countershaft system. The entire FAW Lower Right Centre Shaft Assembly Of The Sub-Box set must be installed with precision preload.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | FAW Lower Right Centre Shaft Assembly Of The Sub-Box |

| Common Name | Auxiliary Box Countershaft / Range Box Countershaft (Lower Right) |

| Transmission Design | Twin-Countershaft Sub-Box (This part is one of the two shafts) |

| Shaft Assembly P/N | 1701515FA0L (Quantity: 1) |

| Bearing Type | Tapered Roller Bearing (Set 33109) |

| Bearing Components | 2x Outer Ring (33109-1), 2x Inner Ring (33109-2) |

| Alignment System | 1x Locating Washer / Shim (1701518-A0L) |

| Primary Function | To carry the High/Low range drive gears and split 50% of the engine torque within the transmission’s sub-box. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.