Welcome to this expert technical analysis of the FAW Sub-Box Shift Cylinder Assembly. This is the complete pneumatic “muscle” and “logic” system that actuates the high/low range splitter for the auxiliary “sub-box” of the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor.

The FAW Sub-Box Shift Cylinder Assembly is the component that physically moves the synchronizer fork to shift the transmission from its “low” range (for pulling heavy loads) to its “high” range (for highway cruising). It is powered by the truck’s main compressed air system and controlled by an electronic solenoid.

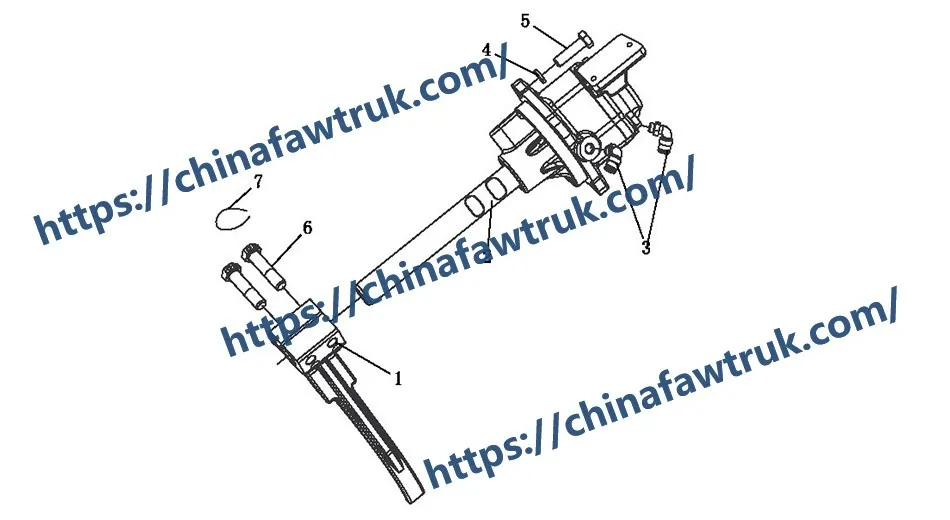

This in-depth guide is a critical resource for professional transmission technicians and fleet managers. We will deconstruct the entire FAW Sub-Box Shift Cylinder Assembly into its 7 serviceable components, including the main cylinder and shaft, the shift fork, the air fittings, and the critical locking hardware.

The heart of the FAW Sub-Box Shift Cylinder Assembly is the ‘Cylinder with fork shaft assembly-sub box’ (1701640BA9P). This is the main pneumatic actuator. This component is a high-reliability air cylinder, typically mounted to the side of the transmission’s rear housing.

Its “logic” is simple but powerful. The cylinder contains an internal piston and a robust seal. When the driver flips the “range selector” switch in the cab, an electronic solenoid (a separate part) directs high-pressure air (100+ PSI) from the truck’s main air system into one of the ’90-degree elbow joint assembly’ (1701755-A8L) ports.

This blast of air slams the piston forward, moving the ‘Cylinder fork shaft assembly’ (1701640AA9P) that is attached to it. When the driver selects the other range, the solenoid vents the air from the first port and pressurizes the second port, slamming the piston and shaft in the opposite direction. This pneumatic “muscle” provides the several hundred pounds of force required to move the synchronizer. A failure of the internal piston seal in this FAW Sub-Box Shift Cylinder Assembly will result in an air leak and a truck that is stuck in either high or low range.

The ‘Fork – sub-box synchronizer’ (1701632AA9P) is the mechanical link between the air cylinder and the gearbox internals. This component of the FAW Sub-Box Shift Cylinder Assembly is a heavy-duty, forged steel “fork.”

It is attached to the end of the pneumatic ‘Cylinder fork shaft’. The two “tines” of the fork ride in a deep groove on the “sliding sleeve” of the sub-box output shaft’s synchronizer. When the air cylinder moves the shaft, this fork moves with it, physically sliding the synchronizer hub to engage either the high-range or low-range gear set.

This fork is a high-wear, high-stress component. The “pads” on the end of the fork tines are in constant, light contact with the spinning synchronizer sleeve. Over hundreds of thousands of shifts, these pads can wear down. Excessive wear will cause a “sloppy” shift, incomplete gear engagement, or “popping out” of range. A cracked fork is a critical failure of the FAW Sub-Box Shift Cylinder Assembly.

The FAW Sub-Box Shift Cylinder Assembly is powered by air, requiring a leak-free plumbing system. The two ’90-degree elbow joint assembly-cylinder’ (1701755-A8L) fittings are the “inlet” and “outlet” ports for the air cylinder.

These are high-pressure, threaded fittings that allow the air lines to be connected at a 90-degree angle, which is essential for routing hoses in the tight confines of the transmission tunnel. A leak in these fittings (or their seals) will not only cause the FAW Sub-Box Shift Cylinder Assembly to become weak or unresponsive, but it will also create a parasitic leak on the truck’s main air brake system, forcing the air compressor to run more often and increasing the risk of a low-air situation.

The mounting hardware for the FAW Sub-Box Shift Cylinder Assembly is designed for maximum security in a high-vibration environment. The ‘Hex flange bolts’ (Q1841040S) and ‘Spring gaskets’ (Q40310) are used to secure the main cylinder body to the transmission housing. The flange head and spring washer work together to prevent the bolts from vibrating loose.

However, the most critical fasteners in this FAW Sub-Box Shift Cylinder Assembly are the ‘Hex head bolt with hole’ (1701633-A7G) units. These two bolts are used for a “cannot-fail” connection, such as securing the ‘Fork’ (1701632AA9P) to the ‘Cylinder fork shaft’ (1701640AA9P).

These bolts have a hole drilled through their heads. This is for the ‘Steel locking wire’ (1701578-A2K). This is a critical safety “logic.” After the technician torques these bolts to the correct specification, this steel wire is threaded through the holes in both bolt heads and then twisted taut. This “lock wire” makes it physically impossible for the bolts to rotate or back out from vibration. A missing lock wire is a sign of an incomplete repair and risks the entire FAW Sub-Box Shift Cylinder Assembly failing.

The following table provides the complete, detailed breakdown of all 7 components identified in the ‘Sub-Box Shift Cylinder Assembly’ diagram for the FAW CA4251P66K24T1A3E5 tractor. The FAW Sub-Box Shift Cylinder Assembly is the “muscle” for the transmission’s range selector.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 1701632AA9P | Fork – sub-box synchronizer | 1 |

| 2 | 1701640AA9P | Cylinder fork shaft assembly-sub box | 1 |

| 1701640BA9P | Cylinder with fork shaft assembly-sub box | 1 | |

| 3 | 1701755-A8L | 90-degree elbow joint assembly-cylinder | 2 |

| 4 | Q40310 | Spring gasket | 4 |

| 5 | Q1841040S | Hex flange bolt, coarse rod (Standard Type) | 4 |

| 6 | 1701633-A7G | Hex head bolt with hole | 2 |

| 7 | 1701578-A2K | Steel locking wire | 1 |

The specifications for the FAW Sub-Box Shift Cylinder Assembly are defined by its function as a high-force, pneumatic actuator for the transmission’s range selector. The FAW Sub-Box Shift Cylinder Assembly is a safety-critical part.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | FAW Sub-Box Shift Cylinder Assembly |

| Actuation Type | Pneumatic (Compressed Air) |

| Control System | ECU-Controlled Solenoid Valve |

| Main Cylinder Assembly | 1x (Part No. 1701640BA9P) |

| Mechanical Linkage | 1x Shift Fork (1701632AA9P) |

| Air Ports | 2x 90-Degree Elbow Joints (1701755-A8L) |

| Safety Feature | 1x Steel Locking Wire (1701578-A2K) |

| Critical Fasteners | 2x Bolts with Hole (1701633-A7G) |

| Primary Function | Provides the physical force to shift the transmission’s auxiliary “sub-box” between High and Low range. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.