Добро пожаловать на этот углубленный технический анализ Задняя подвеска FAW в сборе для кабины. This set of components is one of the most critical structural groups on the FAW Jiefang CA4251P66K24T1A3E5 6×4 дизельный полуприцеп тягач. This is not just a simple mounting point; it is a highly-engineered “логика” сборка. Его ядро “логика” is to simultaneously perform two high-stress jobs: it serves as the rear anchor for the entire cab suspension system *and* the rear fixed mount for the chassis’s front leaf springs.

The Задняя подвеска FAW в сборе для кабины is the primary load-bearing interface connecting the driver’s cab to the truck’s chassis frame. The components detailed here (Часть №. 5001280B91W) are responsible for handling massive longitudinal forces from the chassis suspension *and* vertical forces from the cab suspension (both air spring and coil spring types). This dual-function “логика” is a masterpiece of engineering, saving weight and frame space.

This expert guide is an essential resource for chassis technicians, менеджеры автопарка, и специалисты по запчастям. Мы разберем всю Задняя подвеска FAW в сборе для кабины в свой 4 типы основных компонентов. Мы проанализируем “двойная логика” of the main structural bracket, and then break down the two different, high-tensile fastener groups that are critical for its safety and integrity.

Этот компонент является “дольше” and most substantial part of the Задняя подвеска FAW в сборе для кабины. The ‘Cab rear suspension & front steel plate spring rear fixed combined bracket assy’ (5001280B91W) is the primary structural MSU. В списке запчастей указано два (2), one for the left and one for the right chassis rail.

The “логика” этого “Combined Bracket” is its brilliant, space-saving, dual-function design. It performs two jobs that would normally require two separate, heavy brackets.

Функция 1 Логика: Chassis Spring Mount

The first function is to serve as the *rear fixed mount* for the *chassis’s front leaf spring*. The front of the leaf spring attaches to a shackle that pivots. The rear of that same spring must attach to a fixed, non-moving point on the frame. This bracket is that point.

This means the bracket must be incredibly strong, as it handles all the longitudinal (fore-and-aft) forces of the front axle. All acceleration and braking forces from the front wheels are transferred through the leaf spring and into the chassis *through this single bracket*. This is why it is fabricated from heavy-gauge, high-tensile steel, designed to resist immense shearing and torsional stress.

Функция 2 Логика: Cab Suspension Mount

The second function of the Задняя подвеска FAW в сборе для кабины is to serve as the primary mounting point for the *cab’s rear suspension*. This is the point where the rear cab air spring or coil-over-shock assembly mounts.

This part of the bracket’s “логика” is to handle the vertical (up-and-down) loads of the cab, isolating the driver’s environment from the chassis. By combining these two functions into one part, FAW engineers saved weight, reduced complexity, and saved valuable space on the chassis rail, all while increasing the overall rigidity of the frame at that junction.

Удобство обслуживания (МГУ):

Этот “Combined Bracket” is a primary MSU. It is a non-repairable, safety-critical component. Failures are rare, but can be caused by severe collision damage or (if fasteners are loose) fatigue cracking from vibration. A damaged bracket must be replaced immediately, as a failure here would compromise both the chassis and cab suspension, leading to a loss of vehicle control.

The remaining three component types make up the critical fastening system for the Задняя подвеска FAW в сборе для кабины. This is not a simple collection of hardware; it is a precisely engineered “логика” system designed for clamping force and vibration resistance.

The system consists of 18 болты и 18 nuts in total. This indicates a 9-bolt mounting pattern for *each* of the two main brackets.

Крепежи:

Этот 1:1 ratio of 18 bolts to 18 nuts confirms that these are through-bolt connections, passing completely through the chassis frame rail.

The “логика” of this system is in the details.

Why Two Different Bolts (МГУ 2 & 3)?

The Задняя подвеска FAW в сборе для кабины uses two different part numbers for its bolts (Q1851685T and Q1851695T). The “логика” here is simple: different grip lengths. The 10 bolts of the first type are likely for attaching the main body of the bracket to the flat web of the chassis frame. The 8 bolts of the second type are likely for the part of the bracket that mounts the spring eye, which may be thicker or require a different length bolt.

All of these are “фланец” болты. The flange is an integrated washer. Этот “логика” distributes the clamping force over a wider area, preventing the bolt head from damaging the bracket. It also makes assembly faster.

The “Фланцевой орех” Логика (МГУ 4)

The ‘Hexagon flange nut’ (Q039716) is the most critical piece. Эти 18 nuts are also “фланцевый,” acting as a built-in washer on the nut side. Что еще более важно, these are high-tensile, преобладающий крутящий момент “запирание” орехи. They are either metal-lock (with distorted threads) or nylon-insert (Найлок) орехи.

Этот “запирание” logic is a non-negotiable safety requirement for the Задняя подвеска FAW в сборе для кабины. A standard nut would vibrate loose from road shock and engine harmonics in a very short time. This would cause the bracket to shift, leading to catastrophic failure of the suspension.

Удобство обслуживания (МГУ):

Все 36 fasteners are MSUs. Due to their “отношение крутящего момента к текучести” и “self-locking” nature, these fasteners are strictly **single-use**. В любое время Задняя подвеска FAW в сборе для кабины is unbolted for service, a full new set of 18 болты и 18 nuts *must* be used to guarantee the factory clamping force and vibration resistance.

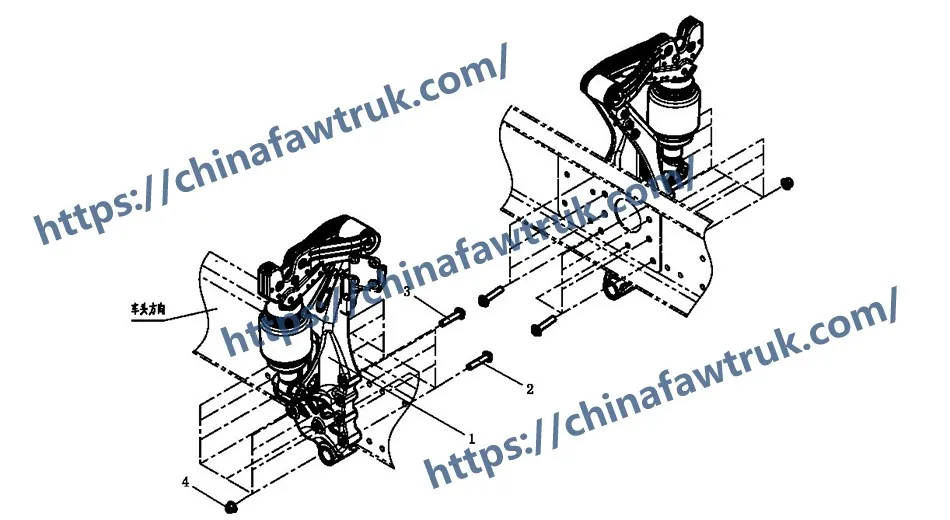

В следующей таблице представлена полная, подробная разбивка всех 4 типы компонентов, указанные в Задняя подвеска FAW в сборе для кабины схема трактора FAW CA4251P66K24T1A3E5.

| Отметка | Часть №. | Наименование | Количество |

|---|---|---|---|

| 1 | 5001280B91W | Cab rear suspension & front steel plate spring rear fixed combined bracket assy | 2 |

| 2 | Q1851685T | Шестигранный фланцевый болт | 10 |

| 3 | Q1851695T | Шестигранный фланцевый болт | 8 |

| 4 | Q039716 | Шестигранная фланцевая гайка | 18 |

Технические характеристики Задняя подвеска FAW в сборе для кабины are defined by its critical, dual-function role as both a chassis spring mount and a cab suspension mount. All fasteners are high-tensile, single-use, anti-vibration components.

| Приложение для автомобиля | FAW Цзефан CA4251P66K24T1A3E5 6×4 Трактор |

| Группа компонентов | Задняя подвеска FAW в сборе для кабины |

| Тип системы | Dual-Function Combined Structural Bracket |

| Логика 1 | Chassis Front Leaf Spring (Rear Fixed Mount) |

| Логика 2 | Cab Rear Suspension (Air/Coil) Устанавливать |

| МГУ 1 (Скобка) | '…Combined bracket assy’ (5001280B91W) – Кол-во 2 |

| МГУ 2 (Bolt A) | ‘Болт с шестигранной головкой’ (Q1851685T) – Кол-во 10 |

| МГУ 3 (Bolt B) | ‘Болт с шестигранной головкой’ (Q1851695T) – Кол-во 8 |

| МГУ 4 (Орех) | ‘Шестигранная фланцевая гайка’ (Q039716) – Кол-во 18 |

| Total Fasteners | 18 Болты, 18 Орехи |

| Логика крепления | Flanged (Распределение нагрузки), Self-Locking (Антивибрационный) |

| Удобство обслуживания | All fasteners are single-use MSUs. Bracket is a non-repairable MSU. |

Запчасти ФАВ, включая блок цилиндров в сборе, тщательно упакованы, чтобы обеспечить безопасную доставку. Каждый компонент закреплен защитными материалами для предотвращения повреждений при транспортировке.. Логистическая сеть гарантирует своевременную доставку по всему миру., поддержка эффективных операций по техническому обслуживанию. Ниже приведено изображение, иллюстрирующее стандартную упаковку запчастей для грузовиков FAW., демонстрация внимания к деталям в обращении и хранении.

Такой подход к упаковке сводит к минимуму риск коррозии или ударного повреждения., обеспечение доставки таких деталей, как блок цилиндров FAW в сборе, в идеальном состоянии.. Клиенты могут положиться на логистику FAW для обеспечения стабильного качества и надежности..