Bem-vindo a esta análise técnica aprofundada do Conjunto de suspensão traseira FAW para a cabine. This set of components is one of the most critical structural groups on the FAW Jiefang CA4251P66K24T1A3E5 6×4 trator semirreboque diesel. This is not just a simple mounting point; it is a highly-engineered “lógica” conjunto. Seu núcleo “lógica” is to simultaneously perform two high-stress jobs: it serves as the rear anchor for the entire cab suspension system *and* the rear fixed mount for the chassis’s front leaf springs.

O Conjunto de suspensão traseira FAW para a cabine is the primary load-bearing interface connecting the driver’s cab to the truck’s chassis frame. The components detailed here (Parte não. 5001280B91W) are responsible for handling massive longitudinal forces from the chassis suspension *and* vertical forces from the cab suspension (both air spring and coil spring types). This dual-function “lógica” is a masterpiece of engineering, saving weight and frame space.

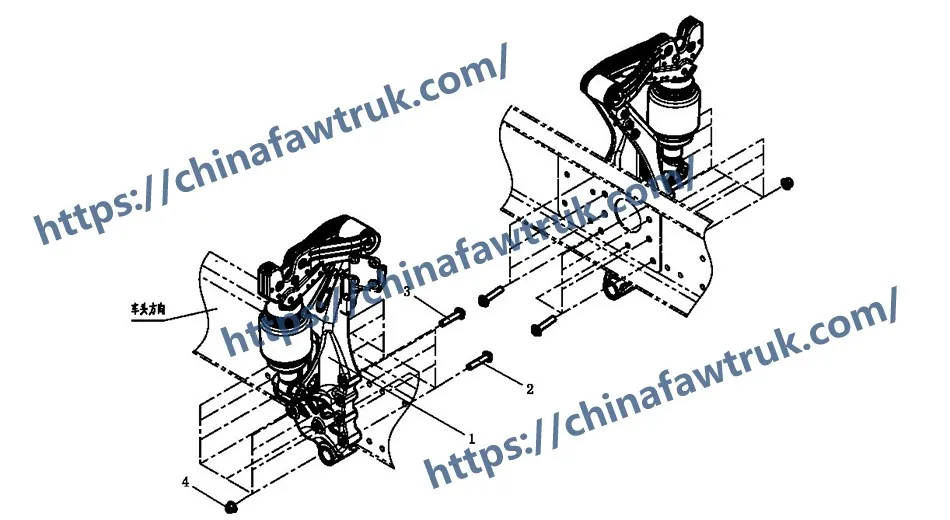

Este guia especializado é um recurso essencial para técnicos de chassis, gestores de frota, e especialistas em peças. Vamos desconstruir todo Conjunto de suspensão traseira FAW para a cabine em seu 4 tipos de componentes primários. Iremos analisar o “lógica dupla” of the main structural bracket, and then break down the two different, high-tensile fastener groups that are critical for its safety and integrity.

Este componente é o “mais longo” and most substantial part of the Conjunto de suspensão traseira FAW para a cabine. The ‘Cab rear suspension & front steel plate spring rear fixed combined bracket assy’ (5001280B91W) is the primary structural MSU. A lista de peças pede dois (2), one for the left and one for the right chassis rail.

O “lógica” disso “Combined Bracket” is its brilliant, space-saving, dual-function design. It performs two jobs that would normally require two separate, heavy brackets.

Função 1 Lógica: Chassis Spring Mount

The first function is to serve as the *rear fixed mount* for the *chassis’s front leaf spring*. The front of the leaf spring attaches to a shackle that pivots. The rear of that same spring must attach to a fixed, non-moving point on the frame. This bracket is that point.

This means the bracket must be incredibly strong, as it handles all the longitudinal (para frente e para trás) forces of the front axle. All acceleration and braking forces from the front wheels are transferred through the leaf spring and into the chassis *through this single bracket*. This is why it is fabricated from heavy-gauge, high-tensile steel, designed to resist immense shearing and torsional stress.

Função 2 Lógica: Cab Suspension Mount

The second function of the Conjunto de suspensão traseira FAW para a cabine is to serve as the primary mounting point for the *cab’s rear suspension*. This is the point where the rear cab air spring or coil-over-shock assembly mounts.

This part of the bracket’s “lógica” is to handle the vertical (up-and-down) loads of the cab, isolating the driver’s environment from the chassis. By combining these two functions into one part, FAW engineers saved weight, reduced complexity, and saved valuable space on the chassis rail, all while increasing the overall rigidity of the frame at that junction.

Facilidade de manutenção (Universidade Estadual de Moscou):

Esse “Combined Bracket” is a primary MSU. It is a non-repairable, componente crítico de segurança. Failures are rare, but can be caused by severe collision damage or (if fasteners are loose) fatigue cracking from vibration. A damaged bracket must be replaced immediately, as a failure here would compromise both the chassis and cab suspension, leading to a loss of vehicle control.

The remaining three component types make up the critical fastening system for the Conjunto de suspensão traseira FAW para a cabine. This is not a simple collection of hardware; it is a precisely engineered “lógica” system designed for clamping force and vibration resistance.

The system consists of 18 bolts and 18 nuts in total. This indicates a 9-bolt mounting pattern for *each* of the two main brackets.

Os fixadores:

Esse 1:1 ratio of 18 parafusos para 18 nuts confirms that these are through-bolt connections, passing completely through the chassis frame rail.

O “lógica” of this system is in the details.

Why Two Different Bolts (Universidade Estadual de Moscou 2 & 3)?

O Conjunto de suspensão traseira FAW para a cabine uses two different part numbers for its bolts (Q1851685T and Q1851695T). O “lógica” here is simple: different grip lengths. O 10 bolts of the first type are likely for attaching the main body of the bracket to the flat web of the chassis frame. O 8 bolts of the second type are likely for the part of the bracket that mounts the spring eye, which may be thicker or require a different length bolt.

All of these are “mesa” parafusos. The flange is an integrated washer. Esse “lógica” distributes the clamping force over a wider area, preventing the bolt head from damaging the bracket. It also makes assembly faster.

O “Porca do flange” Lógica (Universidade Estadual de Moscou 4)

The ‘Hexagon flange nut’ (Q039716) is the most critical piece. Esses 18 nuts are also “flangeado,” acting as a built-in washer on the nut side. Mais importante, these are high-tensile, torque predominante “bloqueio” nozes. They are either metal-lock (with distorted threads) or nylon-insert (Nyloc) nozes.

Esse “bloqueio” logic is a non-negotiable safety requirement for the Conjunto de suspensão traseira FAW para a cabine. A standard nut would vibrate loose from road shock and engine harmonics in a very short time. This would cause the bracket to shift, leading to catastrophic failure of the suspension.

Facilidade de manutenção (Universidade Estadual de Moscou):

Todos 36 fasteners are MSUs. Due to their “torque para rendimento” e “self-locking” nature, these fasteners are strictly **single-use**. A qualquer momento o Conjunto de suspensão traseira FAW para a cabine is unbolted for service, a full new set of 18 bolts and 18 nuts *must* be used to guarantee the factory clamping force and vibration resistance.

A tabela a seguir fornece o completo, detalhamento de todos 4 tipos de componentes identificados no Conjunto de suspensão traseira FAW para a cabine diagrama para o trator FAW CA4251P66K24T1A3E5.

| Marca | Parte não. | Nome da peça | Quantidade |

|---|---|---|---|

| 1 | 5001280B91W | Cab rear suspension & front steel plate spring rear fixed combined bracket assy | 2 |

| 2 | Q1851685T | Parafuso de flange hexagonal | 10 |

| 3 | Q1851695T | Parafuso de flange hexagonal | 8 |

| 4 | Q039716 | Noz de flange hexágono | 18 |

As especificações para o Conjunto de suspensão traseira FAW para a cabine are defined by its critical, dual-function role as both a chassis spring mount and a cab suspension mount. All fasteners are high-tensile, uso único, anti-vibration components.

| Aplicação em veículos | FAW Jiefang CA4251P66K24T1A3E5 6×4 Trator |

| Grupo de Componentes | Conjunto de suspensão traseira FAW para a cabine |

| Tipo de sistema | Dual-Function Combined Structural Bracket |

| Lógica 1 | Chassis Front Leaf Spring (Rear Fixed Mount) |

| Lógica 2 | Cab Rear Suspension (Air/Coil) Mount |

| Universidade Estadual de Moscou 1 (Suporte) | '…Combined bracket assy’ (5001280B91W) – Quantidade 2 |

| Universidade Estadual de Moscou 2 (Bolt A) | 'Parafuso de flange hexagonal’ (Q1851685T) – Quantidade 10 |

| Universidade Estadual de Moscou 3 (Bolt B) | 'Parafuso de flange hexagonal’ (Q1851695T) – Quantidade 8 |

| Universidade Estadual de Moscou 4 (Noz) | ‘Hexagon flange nut’ (Q039716) – Quantidade 18 |

| Total Fasteners | 18 Parafusos, 18 Nozes |

| Lógica do Fixador | Flanged (Distribuição de carga), Self-Locking (Antivibração) |

| Facilidade de manutenção | All fasteners are single-use MSUs. Bracket is a non-repairable MSU. |

Peças FAW, incluindo o conjunto do bloco de cilindros, são embalados com cuidado para garantir uma entrega segura. Cada componente é protegido por materiais de proteção para evitar danos durante o transporte. A rede logística garante envios pontuais em todo o mundo, apoiando operações de manutenção eficientes. Abaixo está uma imagem ilustrando a embalagem padrão para peças de caminhão FAW, mostrando a atenção aos detalhes no manuseio e armazenamento.

Esta abordagem de embalagem minimiza o risco de corrosão ou danos por impacto, garantindo que peças como o conjunto do bloco de cilindros FAW cheguem em perfeitas condições. Os clientes podem confiar na logística da FAW para obter qualidade e confiabilidade consistentes.