Welcome to this critical technical breakdown of the Передняя подвеска FAW в сборе для кабины (Lower Mounts). This system is the structural foundation for the cab-over-engine suspension on the FAW Jiefang CA4251P66K24T1A3E5 6×4 дизельный полуприцеп тягач. Это не одна часть, но “логика” assembly of heavy-duty brackets and specialized, high-tensile fasteners. Его ядро “логика” is to provide the lower anchor point for the cab’s main shock absorbers and springs (both coil and air), isolating the driver from the severe vibration and shock of the chassis.

The Передняя подвеска FAW в сборе для кабины is the critical interface between the chassis frame and the cab’s vibration-damping system. The components detailed here are designed for universality, supporting both coil spring and air spring front suspension setups. A secure, geometrically perfect front suspension is essential for driver comfort, контроль, and the prevention of long-term fatigue on both the driver and the cab structure itself.

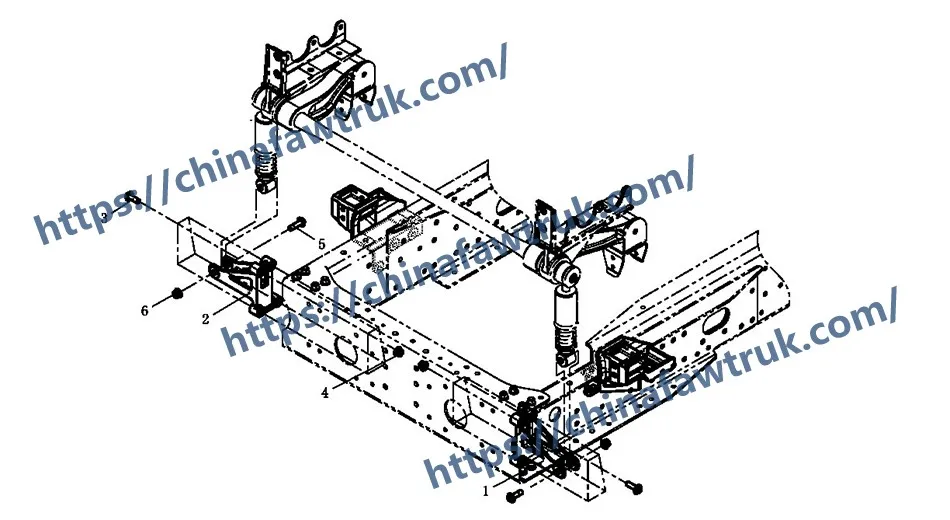

This in-depth guide is an essential resource for chassis technicians, alignment specialists, и менеджеры по запчастям. Мы разберем всю Передняя подвеска FAW в сборе для кабины в свой 6 типы основных компонентов. Мы проанализируем “Левый” и “Верно” structural brackets as the main MSUs, и, just as importantly, deconstruct the two different sets of high-tensile, виброустойчивые крепления, each with its own specific “логика.”

This section is the “дольше” and most substantial part of the Передняя подвеска FAW в сборе для кабины. The primary components are the two main “large purchase” МГУ:

These two components are the bedrock of the front cab suspension. Их “логика” is to serve as the structural anchor point, transferring the entire static and dynamic load of the cab’s front end from the shock absorber and spring into the truck’s main chassis frame.

Construction and Logic:

These brackets are not simple cast iron parts. They are high-strength, fabricated steel assemblies. Этот “логика” of using fabricated (сварной) heavy-gauge plate steel is for superior fatigue resistance. A cab suspension is subjected to millions of micro-vibrations and high-impact shocks (from potholes) during its lifespan. A cast part could become brittle and crack; this fabricated design provides the necessary ductility and strength to survive.

As the ‘Left’ и «Правильно’ designations imply, these are mirror-image components. Their geometry is critical. The location of the main mounting holes (for attaching to the frame) and the shock absorber mounting holes are precision-drilled. If one of these brackets is bent or damaged in a collision, the cab will sit “crooked” on the chassis, leading to alignment issues, driver discomfort, and uneven stress on the other suspension components.

Удобство обслуживания (МГУ):

These brackets are primary MSUs. Неудачи случаются редко, но если это произойдет (typically from collision damage or a fatigue crack in a weld), the entire bracket is replaced. It is secured to the chassis frame by the 8-bolt fastener set (МГУ 3 & 4) and serves as the mounting point for the shock absorber via the 2-bolt fastener set (МГУ 5 & 6). A key part of the Передняя подвеска FAW в сборе для кабины, its integrity is paramount.

This group represents the first, and most numerous, set of fasteners in the Передняя подвеска FAW в сборе для кабины. It consists of eight (8) ‘Hexagon flange bolts’ (01841470Т) and eight (8) ‘Hexagon head self-locking nuts’ (Q032614).

The “логика” of this 8-bolt/8-nut system is clear: this is the high-strength hardware used to mount the two brackets (МГУ 1 & 2) *to the main chassis frame*. This implies a secure, four-bolt pattern for each of the two brackets.

Болт (01841470Т): This is a ‘Hexagon flange bolt’. The “фланец” logic is critical. The flange is a built-in, non-rotating, integrated washer. This design distributes the clamping force of the bolt head over a wider surface area, preventing the bolt from “sinking” into the bracket’s mounting holes. It also makes assembly faster, as the technician does not need to fumble with a separate washer.

Орех (Q032614): This is a ‘Hexagon head self-locking nut’. This is the most important “логика” in the entire assembly. Это “Найлок” (nylon-insert) или “преобладающий крутящий момент” орех. The nylon insert creates intense friction on the bolt threads, which *prevents the nut from backing off due to vibration*. On a component as critical as the Передняя подвеска FAW в сборе для кабины, a standard nut would vibrate loose in days. This self-locking logic is a non-negotiable safety feature.

Удобство обслуживания (МГУ): This entire set of 16 fasteners are MSUs. Критически, self-locking nuts are *single-use items*. Once a Q032614 nut is removed, the nylon insert is compromised and it *must not* be re-used. A new self-locking nut must be used to guarantee the anti-vibration logic.

This second, smaller set of fasteners is functionally different from the first. It consists of two (2) ‘Hexagon flange bolts’ (T18414100T) и два (2) ‘Hexagon flange nuts’ (Q39614).

The “логика” of this 2-bolt/2-nut system (one per side) indicates it is the hardware used to attach the *bottom of the shock absorber* (or air spring) *to the bracket*.

Болт (T18414100T): The part name, ‘Болт с шестигранной головкой, tapered guide end’, tells the whole story. The “tapered guide end” является критическим “логика” here. This bolt is specifically designed to aid in assembly. The tapered point acts as an alignment dowel, allowing the technician to easily guide the bolt through the bracket hole and the heavy, hard-to-move “глаз” of the shock absorber. Этот “alignment logic” saves significant time and frustration during service.

Орех (Q39614): This is a ‘Hexagon flange nut’. Like the other bolts, the flange acts as an integrated washer. This nut is torqued to a high specification against the bolt to create the clamping force necessary to hold the shock absorber in place, позволяя Передняя подвеска FAW в сборе для кабины to properly absorb and dampen road forces.

В следующей таблице представлена полная, подробная разбивка всех 6 типы компонентов, указанные в Передняя подвеска FAW в сборе для кабины (Ниже) схема трактора FAW CA4251P66K24T1A3E5.

| Отметка | Часть №. | Наименование | Количество |

|---|---|---|---|

| 1 | 5001161A91W | Front suspension shock absorber left lower bracket | 1 |

| 2 | 5001162A91W | Front suspension shock absorber right lower bracket | 1 |

| 3 | 01841470Т | Шестигранный фланцевый болт (coarse thread) (стандартный тип) | 8 |

| 4 | Q032614 | Hexagon head self-locking nut | 8 |

| 5 | T18414100T | Шестигранный фланцевый болт, tapered guide end | 2 |

| 6 | Q39614 | Шестигранная фланцевая гайка | 2 |

Технические характеристики Передняя подвеска FAW в сборе для кабины are defined by its function as the primary structural mounting point for the cab’s damping system. It is engineered for high strength and vibration resistance.

| Приложение для автомобиля | FAW Цзефан CA4251P66K24T1A3E5 6×4 Трактор |

| Группа компонентов | Передняя подвеска FAW в сборе для кабины (Ниже) |

| Тип подвески | Universal (Coil Spring / Air Spring compatible) |

| МГУ 1 (Левый кронштейн) | 5001161A91W |

| МГУ 2 (Правый кронштейн) | 5001162A91W |

| МГУ 3 & 4 (Bracket-to-Frame) | 8x Flange Bolt (01841470Т) + 8x Self-Locking Nut (Q032614) |

| МГУ 5 & 6 (Damper-to-Bracket) | 2x Tapered Flange Bolt (T18414100T) + 2x Flange Nut (Q39614) |

| Bracket Material | Fabricated High-Strength Steel |

| Логика крепления | Фланец (Anti-Washer), Self-Locking (Антивибрационный), Taper (Выравнивание) |

Запчасти ФАВ, включая блок цилиндров в сборе, тщательно упакованы, чтобы обеспечить безопасную доставку. Каждый компонент закреплен защитными материалами для предотвращения повреждений при транспортировке.. Логистическая сеть гарантирует своевременную доставку по всему миру., поддержка эффективных операций по техническому обслуживанию. Ниже приведено изображение, иллюстрирующее стандартную упаковку запчастей для грузовиков FAW., демонстрация внимания к деталям в обращении и хранении.

Такой подход к упаковке сводит к минимуму риск коррозии или ударного повреждения., обеспечение доставки таких деталей, как блок цилиндров FAW в сборе, в идеальном состоянии.. Клиенты могут положиться на логистику FAW для обеспечения стабильного качества и надежности..