Welcome to this critical technical breakdown of the Conjunto de suspensión delantera FAW para la cabina (Lower Mounts). This system is the structural foundation for the cab-over-engine suspension on the FAW Jiefang CA4251P66K24T1A3E5 6×4 tractor semirremolque diésel. Esta no es una sola parte, pero un “lógica” assembly of heavy-duty brackets and specialized, high-tensile fasteners. Su núcleo “lógica” is to provide the lower anchor point for the cab’s main shock absorbers and springs (both coil and air), isolating the driver from the severe vibration and shock of the chassis.

El Conjunto de suspensión delantera FAW para la cabina is the critical interface between the chassis frame and the cab’s vibration-damping system. The components detailed here are designed for universality, supporting both coil spring and air spring front suspension setups. A secure, geometrically perfect front suspension is essential for driver comfort, control, and the prevention of long-term fatigue on both the driver and the cab structure itself.

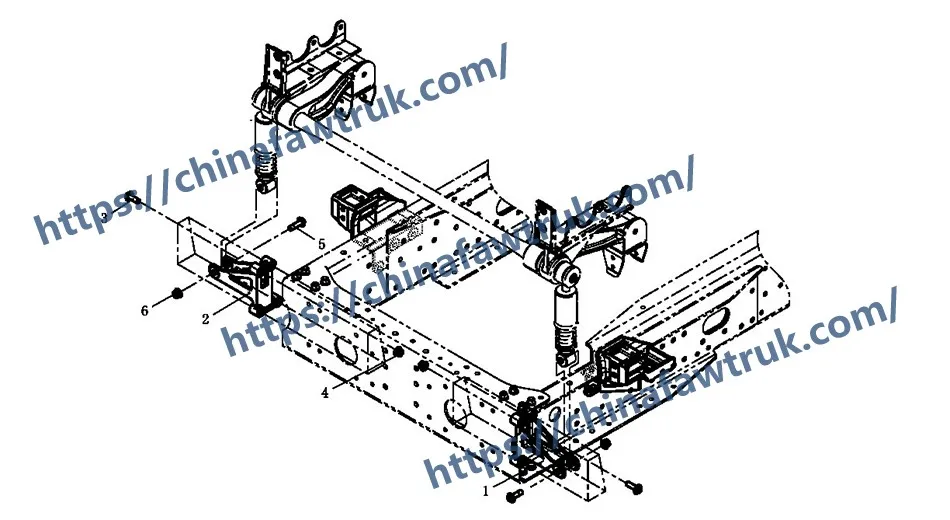

This in-depth guide is an essential resource for chassis technicians, alignment specialists, y gerentes de repuestos. Deconstruiremos todo Conjunto de suspensión delantera FAW para la cabina en su 6 tipos de componentes primarios. Analizaremos el “Izquierda” y “Bien” structural brackets as the main MSUs, y, just as importantly, deconstruct the two different sets of high-tensile, vibration-proof fasteners, each with its own specific “lógica.”

Esta sección es la “más extenso” y la parte más sustancial de la Conjunto de suspensión delantera FAW para la cabina. The primary components are the two main “large purchase” MSU:

These two components are the bedrock of the front cab suspension. Su “lógica” is to serve as the structural anchor point, transferring the entire static and dynamic load of the cab’s front end from the shock absorber and spring into the truck’s main chassis frame.

Construction and Logic:

These brackets are not simple cast iron parts. They are high-strength, fabricated steel assemblies. Este “lógica” of using fabricated (soldado) heavy-gauge plate steel is for superior fatigue resistance. A cab suspension is subjected to millions of micro-vibrations and high-impact shocks (from potholes) during its lifespan. A cast part could become brittle and crack; this fabricated design provides the necessary ductility and strength to survive.

As the ‘Left’ y 'correcto’ designations imply, these are mirror-image components. Their geometry is critical. The location of the main mounting holes (for attaching to the frame) and the shock absorber mounting holes are precision-drilled. If one of these brackets is bent or damaged in a collision, the cab will sit “crooked” on the chassis, leading to alignment issues, driver discomfort, and uneven stress on the other suspension components.

Utilidad (Universidad Estatal de Michigan):

These brackets are primary MSUs. Failure is rare, but if it occurs (typically from collision damage or a fatigue crack in a weld), the entire bracket is replaced. It is secured to the chassis frame by the 8-bolt fastener set (MSU 3 & 4) and serves as the mounting point for the shock absorber via the 2-bolt fastener set (MSU 5 & 6). Una parte clave del Conjunto de suspensión delantera FAW para la cabina, its integrity is paramount.

This group represents the first, and most numerous, set of fasteners in the Conjunto de suspensión delantera FAW para la cabina. It consists of eight (8) «Pernos de brida hexagonal’ (01841470t) y ocho (8) ‘Hexagon head self-locking nuts’ (Q032614).

El “lógica” of this 8-bolt/8-nut system is clear: this is the high-strength hardware used to mount the two brackets (MSU 1 & 2) *to the main chassis frame*. This implies a secure, four-bolt pattern for each of the two brackets.

Tornillo (01841470t): This is a ‘Hexagon flange bolt’. El “brida” logic is critical. The flange is a built-in, non-rotating, lavadora integrada. This design distributes the clamping force of the bolt head over a wider surface area, evitando que el perno “sinking” into the bracket’s mounting holes. También agiliza el montaje, as the technician does not need to fumble with a separate washer.

Tuerca (Q032614): This is a ‘Hexagon head self-locking nut’. This is the most important “lógica” in the entire assembly. Este es un “niloc” (inserto de nailon) o “par predominante” tuerca. The nylon insert creates intense friction on the bolt threads, which *prevents the nut from backing off due to vibration*. On a component as critical as the Conjunto de suspensión delantera FAW para la cabina, a standard nut would vibrate loose in days. This self-locking logic is a non-negotiable safety feature.

Utilidad (Universidad Estatal de Michigan): This entire set of 16 los sujetadores son MSU. críticamente, self-locking nuts are *single-use items*. Once a Q032614 nut is removed, the nylon insert is compromised and it *must not* be re-used. A new self-locking nut must be used to guarantee the anti-vibration logic.

This second, smaller set of fasteners is functionally different from the first. It consists of two (2) «Pernos de brida hexagonal’ (T18414100T) y dos (2) ‘Hexagon flange nuts’ (Q39614).

El “lógica” of this 2-bolt/2-nut system (one per side) indicates it is the hardware used to attach the *bottom of the shock absorber* (or air spring) *to the bracket*.

Tornillo (T18414100T): The part name, «Perno de brida hexagonal, tapered guide end’, tells the whole story. El “tapered guide end” es el critico “lógica” aquí. This bolt is specifically designed to aid in assembly. The tapered point acts as an alignment dowel, allowing the technician to easily guide the bolt through the bracket hole and the heavy, hard-to-move “ojo” of the shock absorber. Este “alignment logic” saves significant time and frustration during service.

Tuerca (Q39614): This is a ‘Hexagon flange nut’. Like the other bolts, the flange acts as an integrated washer. This nut is torqued to a high specification against the bolt to create the clamping force necessary to hold the shock absorber in place, permitiendo el Conjunto de suspensión delantera FAW para la cabina to properly absorb and dampen road forces.

La siguiente tabla proporciona la información completa, desglose detallado de todos 6 tipos de componentes identificados en el Conjunto de suspensión delantera FAW para la cabina (Más bajo) diagrama para el tractor FAW CA4251P66K24T1A3E5.

| Marca | Número de pieza. | Nombre de la pieza | Cantidad |

|---|---|---|---|

| 1 | 5001161A91W | Front suspension shock absorber left lower bracket | 1 |

| 2 | 5001162A91W | Front suspension shock absorber right lower bracket | 1 |

| 3 | 01841470t | Perno de brida hexagonal (coarse thread) (tipo estándar) | 8 |

| 4 | Q032614 | Hexagon head self-locking nut | 8 |

| 5 | T18414100T | Perno de brida hexagonal, tapered guide end | 2 |

| 6 | Q39614 | Nuez de brida hexágono | 2 |

Las especificaciones para el Conjunto de suspensión delantera FAW para la cabina are defined by its function as the primary structural mounting point for the cab’s damping system. It is engineered for high strength and vibration resistance.

| Solicitud de vehículo | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Grupo de componentes | Conjunto de suspensión delantera FAW para la cabina (Más bajo) |

| Suspension Type | Universal (Muelle en espiral / Air Spring compatible) |

| Universidad Estatal de Michigan 1 (Soporte izquierdo) | 5001161A91W |

| Universidad Estatal de Michigan 2 (Soporte derecho) | 5001162A91W |

| MSU 3 & 4 (Bracket-to-Frame) | 8x Flange Bolt (01841470t) + 8x Self-Locking Nut (Q032614) |

| MSU 5 & 6 (Damper-to-Bracket) | 2x Tapered Flange Bolt (T18414100T) + 2x Flange Nut (Q39614) |

| Bracket Material | Fabricated High-Strength Steel |

| Lógica de sujetadores | Brida (Anti-Washer), Autobloqueo (Antivibración), Taper (Alineación) |

piezas FAW, incluido el conjunto del bloque de cilindros, Se empaquetan con cuidado para garantizar una entrega segura.. Cada componente está asegurado con materiales protectores para evitar daños durante el transporte.. La red logística garantiza envíos puntuales en todo el mundo., apoyando operaciones de mantenimiento eficientes. A continuación se muestra una imagen que ilustra el embalaje estándar de las piezas de camiones FAW., mostrando la atención al detalle en el manejo y almacenamiento.

Este enfoque de embalaje minimiza el riesgo de corrosión o daños por impacto., asegurando que piezas como el conjunto de bloque de cilindros FAW lleguen en perfectas condiciones. Los clientes pueden confiar en la logística de FAW para obtener calidad y confiabilidad constantes.