Welcome to the complete technical guide for the Крышка головки блока цилиндров и крышка маслозаливной горловины FAW система, a crucial set of components for the FAW Jiefang CA4251P66K24T1A3E5 6×4 дизельный полуприцеп тягач. This assembly is the first line of defense for the engine’s valvetrain.

Эта система, а Крышка головки блока цилиндров и крышка маслозаливной горловины FAW, serves multiple critical functions: it seals the top of the engine, protecting the delicate camshafts and valve gear from dirt and moisture. It also contains the engine oil that lubricates these components, предотвращение утечек. Более того, it houses the engine’s crankcase ventilation system and provides the service point for adding engine oil.

This guide is designed for professional technicians and parts managers, providing a detailed breakdown of the entire Крышка головки блока цилиндров и крышка маслозаливной горловины FAW сборка. We will deconstruct the system into its smallest serviceable units, from the main cover and its gasket to the specialized bolts and the oil cap assembly, ensuring every service is performed accurately.

The largest component in this assembly is the ‘Cylinder Head Cover’ (1003031-81Д). On modern diesel engines, this part is a highly engineered component, often made from a high-strength, glass-filled composite (пластик) or a lightweight cast aluminum. A composite design is often preferred as it reduces engine-top weight and is significantly quieter, damping the “тиканье” sound of the valvetrain.

This component’s primary function is to act as a static seal, but its secondary function is just as critical. This cover contains the engine’s Positive Crankcase Ventilation (ПКВ) система. Пока двигатель работает, some combustion gases (“прорыв”) inevitably push past the piston rings and into the crankcase. This builds pressure and must be ventilated.

Однако, these gases are mixed with a fine mist of hot engine oil. The Крышка головки блока цилиндров и крышка маслозаливной горловины FAW assembly is designed with a complex series of internal channels, baffles, and oil-air separators. As the crankcase gases flow into the cover, they are forced through this “labyrinth.” The heavier liquid oil droplets collide with the baffle walls, конденсироваться, and drain back into the cylinder head, returning to the oil sump.

The remaining oil *vapor* (along with the blow-by gases) is then drawn out of a port on the cover and routed into the engine’s air intake, just before the turbocharger. This allows the unburnt hydrocarbons to be re-burned, which is a critical emissions control function. If this internal baffle system becomes clogged or fails, the engine will draw liquid oil into the intake, leading to high oil consumption, blue smoke from the exhaust, and the fouling of the turbocharger and intercooler.

The ‘Cylinder Head Cover’ itself is a static part; the ‘Cylinder Head Cover Gasket’ (1003041-81Д) is the active component that makes the seal. This is the single most common failure point in the Крышка головки блока цилиндров и крышка маслозаливной горловины FAW система.

This is not a simple paper gasket. Это “профиль” прокладка, precision-molded from an advanced, oil-resistant elastomer (like silicone or FKM/Viton). It is designed to sit perfectly within a groove that runs along the entire perimeter of the plastic or aluminum cover. It also includes integrated O-rings that loop around the bolt holes and the spark plug tubes (Если применимо), creating a complete, one-piece sealing solution.

This gasket lives in a brutal environment, subjected to constant engine vibration, heat cycles (from ambient temperature to over 100°C and back), and continuous exposure to hot engine oil. Over many thousands of hours, this elastomer will harden, стать хрупким, and compress. Когда это произойдет, it loses its sealing ability, and oil begins to weep.

A leaking head cover gasket is a common maintenance item. The diagnosis is simple: visual signs of “sweating” or active oil drips from the seam between the head and the cover. Often, this oil will drip onto the hot exhaust manifold, creating a distinct burning oil smell. Replacing this gasket is a standard service procedure, but it must be done correctly by following the precise bolt-tightening sequence to avoid damaging the new gasket.

The gasket’s seal is only as good as the clamping force applied to it. This is the job of the 17 ‘Cylinder Head Cover Bolt Assembly’ единицы (1003060-81Д). Большое количество 17 bolts is necessary to distribute the clamping pressure evenly across the long, complex perimeter of the gasket, ensuring there are no “loose spots” where oil could escape.

These are designated as a “bolt assembly” because they are not just simple bolts. Each one almost certainly includes a captive metal washer and, самое главное, a rubber isolator or “grommet.” This grommet is a critical part of the Крышка головки блока цилиндров и крышка маслозаливной горловины FAW дизайн.

This rubber grommet serves two functions. Первый, it seals the bolt hole, preventing oil from leaking up the bolt threads and pooling on top of the cover. Второй, it acts as a “soft torque” останавливаться. When installing a composite cover, over-tightening is a major risk; it can crack the cover or “расколоть” the gasket. These bolts are not designed to be tightened with high force. The technician tightens them until the metal washer compresses the rubber grommet. Это обеспечивает “built-in” torque limit and isolates the cover from engine vibration, preventing the bolts from backing out.

The final two components form the primary user interaction point of the Крышка головки блока цилиндров и крышка маслозаливной горловины FAW система. The ‘Oil Filler Cap’ (1003037-29Д) съемный, twist-lock cap that allows a technician or operator to add engine oil.

The functional part, однако, is the ‘Seal Ring-Oil Filler Cap’ (1003036-29Д). This is a simple O-ring or flat rubber gasket that sits in a groove on the cap. Its function is far more important than just preventing oil from “брызги” вне. This seal is a critical part of the crankcase ventilation system.

The PCV system, described earlier, is designed to maintain a slight *vacuum* inside the engine’s crankcase. If this cap seal is missing, треснутый, or hardened, it creates a “vacuum leak.” This allows un-metered, *unfiltered* air to be sucked directly into the engine’s valvetrain. This dirty air contaminates the engine oil and bypasses the PCV’s oil-separating baffles.

A failed cap seal can disrupt the delicate balance of the PCV, potentially leading to incorrect pressure in the crankcase. In a worst-case scenario, if the PCV system gets clogged, a failed cap seal can become an *outlet* for crankcase pressure, pushing oily fumes out and making a mess of the engine bay. Этот маленький, inexpensive ‘Seal Ring’ is a critical component for maintaining the health of the entire engine and the proper function of the Крышка головки блока цилиндров и крышка маслозаливной горловины FAW.

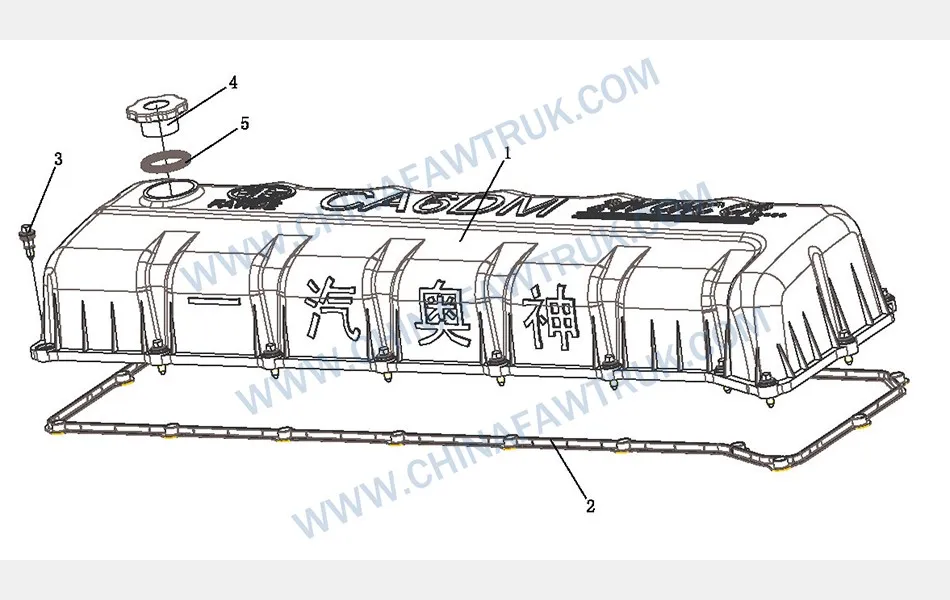

В следующей таблице представлена полная, detailed breakdown of all components identified in the ‘Cylinder Head Cover and Oil Filler Cap’ схема трактора FAW CA4251P66K24T1A3E5.

| Отметка | Часть №. | Наименование | Количество |

|---|---|---|---|

| 1 | 1003031-81Д | Крышка головки цилиндра | 1 |

| 2 | 1003041-81Д | Прокладка крышки головки блока цилиндров | 1 |

| 3 | 1003060-81Д | Болт крышки головки блока цилиндров в сборе | 17 |

| 4 | 1003037-29Д | Масляная крышка | 1 |

| 5 | 1003036-29Д | Seal Ring-Oil Filler Cap | 1 |

Технические характеристики Крышка головки блока цилиндров и крышка маслозаливной горловины FAW are centered on its role as the primary sealing and ventilation system for the engine’s valvetrain.

| Приложение для автомобиля | FAW Цзефан CA4251P66K24T1A3E5 6×4 Трактор |

| Группа компонентов | Cylinder Head Cover And Oil Filler Cap |

| Номер детали основной крышки. | 1003031-81Д |

| Main Gasket Part No. | 1003041-81Д (Profile Elastomer Gasket) |

| Система крепления | 17x Bolt Assemblies (1003060-81Д) with Isolators |

| Oil Service Cap Part No. | 1003037-29Д |

| Oil Cap Seal Part No. | 1003036-29Д (уплотнительное кольцо / Печать кольцо) |

| Основная функция | Seals valvetrain, contains oil, integrates PCV system, provides oil filler access. |

Запчасти ФАВ, включая блок цилиндров в сборе, тщательно упакованы, чтобы обеспечить безопасную доставку. Каждый компонент закреплен защитными материалами для предотвращения повреждений при транспортировке.. Логистическая сеть гарантирует своевременную доставку по всему миру., поддержка эффективных операций по техническому обслуживанию. Ниже приведено изображение, иллюстрирующее стандартную упаковку запчастей для грузовиков FAW., демонстрация внимания к деталям в обращении и хранении.

Такой подход к упаковке сводит к минимуму риск коррозии или ударного повреждения., обеспечение доставки таких деталей, как блок цилиндров FAW в сборе, в идеальном состоянии.. Клиенты могут положиться на логистику FAW для обеспечения стабильного качества и надежности..