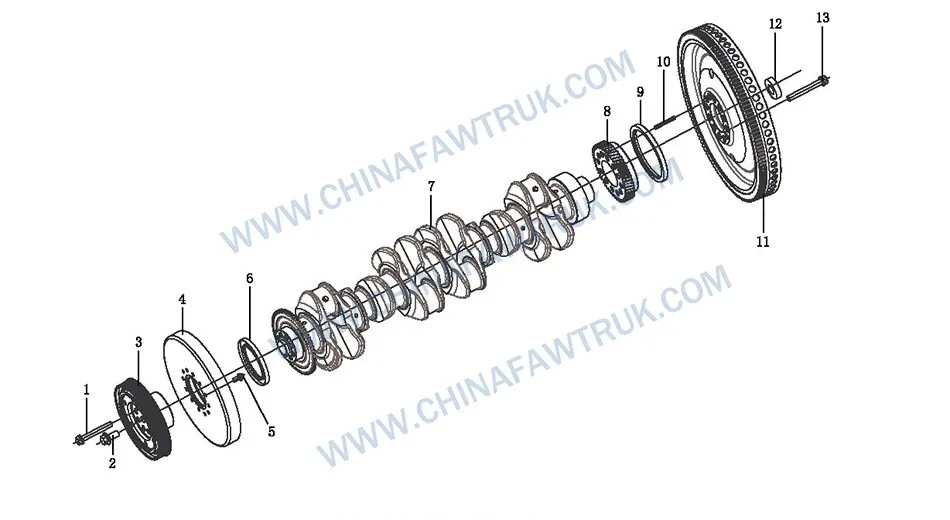

Virabrequim Russo FAW: 13 Componentes Críticos para Torque Ártico Imparável

O Virabrequim Russo FAW is the backbone of the CA3250P66K24L1TE5Z powertrain, converting piston force into the rotational energy that drives heavy loads across the frozen Russian tundra. This assembly includes sophisticated damping and sealing technologies designed to withstand extreme thermal contraction. This guide dissects the flywheel, damper, and gears essential for maintaining engine balance in sub-zero conditions.

Virabrequim Russo FAW

Harmonic Control: The Front End Architecture

A longevidade do Virabrequim Russo FAW depends heavily on its ability to manage torsional vibration. The primary component in this defense is the Conjunto de amortecedor de óleo de silicone (Parte não. 1005195-81D). Unlike solid rubber dampers which can become brittle and crack in temperatures below -40°C, this fluid-filled unit utilizes a high-viscosity silicone fluid. This fluid maintains its damping properties even in extreme cold, absorbing the twisting forces generated by the firing pulses of the six-cylinder engine and preventing crankshaft fatigue failure.

Securing this heavy damper to the nose of the Virabrequim Russo FAW requires high-tensile fasteners. The assembly uses eight specific Damper Bolts (Parte não. 1005048-53D). These bolts are subjected to constant shear loads and rotational acceleration. Using standard grade bolts here is a recipe for disaster; if they shear, the damper can detach, causing catastrophic damage to the radiator and front timing cover. The correct torque application on these bolts is critical to ensure the damper acts as a unified mass with the crank.

Driven by the crankshaft nose is the Poly-V Belt Pulley (Parte não. 1005046A81D). This pulley powers the fan, alternador, and water pump. No Virabrequim Russo FAW conjunto, this pulley is precision-balanced to ensure it does not induce secondary vibrations. The surface finish of the pulley grooves is treated to resist corrosion from road salt and moisture, ensuring that the belt does not slip during the high-load demand of a cold winter startup when the alternator is working at maximum capacity.

Precision Gearing: Timing and Oil Pump Synchronization

Behind the front cover, o Virabrequim Russo FAW drives the engine’s vital systems through a series of robust gears. O Equipamento de tempo do eixo de manivela (Parte não. 1005037-81D) is shrink-fitted onto the crankshaft snout. This gear is responsible for synchronizing the camshaft and injection pump. Na especificação russa, the metallurgy of this gear is hardened to resist tooth wear caused by the high-torque backlash that occurs during cold idling. Any wear here alters injection timing, leading to hard starts and white smoke.

Adjacent to the timing gear is the Crankshaft Oil Pump Gear Assembly (Parte não. 1005015-81D). This component is arguably the most critical auxiliary drive in the entire Virabrequim Russo FAW sistema. It drives the oil pump which lubricates the main bearings. The gear profile is designed for quiet operation and maximum contact area. If this gear fails or slips, oil pressure drops instantly, leading to a seized engine. The press-fit tolerance of this gear on the crankshaft journal is measured in microns to prevent slippage under load.

The precise alignment of these gears is maintained by the Drive Gear and Flywheel Dowel Pin (Parte não. 1005031-29D). Embora pequeno, this pin ensures that the timing gear is indexed correctly relative to Top Dead Center (TDC). No Virabrequim Russo FAW conjunto, this pin must resist shearing forces during rapid engine deceleration. It acts as the mechanical reference point for the entire engine’s timing logic, ensuring that valve events and fuel injection occur at the precise millisecond required for combustion.

Sealing Architecture: Preventing Oil Loss in Arctic Cold

Retaining engine oil in sub-zero temperatures is a significant engineering challenge for the Virabrequim Russo FAW. The front of the engine is sealed by the Crankshaft Front Oil Seal Assembly (Parte não. 1005050-53D). This seal features a specialized lip material, often PTFE or Viton, designed to remain flexible at -40°C. Standard rubber seals would harden and groove the crankshaft sealing surface, levando a vazamentos. This assembly includes a dust lip to prevent road grit and ice slurry from entering the engine and damaging the primary oil seal lip.

At the transmission end, o Crankshaft Rear Oil Seal Assembly (Parte não. 1005060-53D) handles a much larger diameter sealing surface. This seal is critical because replacing it requires separating the transmission from the engine—a major labor operation. O Virabrequim Russo FAW utilizes a cassette-style rear seal in this application. This design includes a wear sleeve that rotates with the crank, meaning the sealing lip rubs internally against the sleeve rather than the expensive crankshaft journal itself, protecting the shaft from wear grooves over time.

The integrity of these seals is vital for the Virabrequim Russo FAW ambiente. A rear main seal leak can contaminate the clutch disc, causing slippage and failure on steep icy grades. Portanto, the manufacturing tolerance of the seal housing and the surface finish of the crankshaft journals are inspected to rigorous standards. Fleet operators in Russia prioritize using these genuine, cold-weather rated seals to avoid the downtime associated with “molhado” bell housings and oil starvation.

Inertia and Transmission: O conjunto do volante

The output end of the Virabrequim Russo FAW is dominated by the massive Conjunto do volante (Parte não. 1005120-73D). This cast iron component serves three functions: it carries the ring gear for the starter motor, provides a friction surface for the clutch, and acts as an energy reservoir to smooth out the engine’s power pulses. The thermal mass of this flywheel is calculated to absorb the heat generated by clutch slippage during heavy launches in deep snow without warping or heat checking.

Securing this heavy rotating mass are 12 de alta resistência Flywheel Bolts (Parte não. 1005071-81D). These are torque-to-yield fasteners that must be tightened in a specific star pattern. No Virabrequim Russo FAW conjunto, these bolts undergo immense shear stress every time the clutch is engaged. Reusing old bolts is strictly prohibited as they stretch during initial installation; reused bolts can snap, causing the flywheel to detach—a catastrophic failure that can destroy the transmission housing and engine block.

Embedded in the center of the flywheel is the Input Shaft Front Bearing (Parte não. 60305), often called the pilot bearing. This bearing supports the tip of the transmission input shaft. Embora pequeno, it is crucial for the Virabrequim Russo FAW sistema. A seized pilot bearing will keep the transmission shaft spinning even when the clutch is depressed, making gear changes impossible. The genuine FAW bearing uses a low-temperature grease that does not solidify in the Russian winter, ensuring smooth shifting from a cold start.

Lista detalhada de componentes

A tabela a seguir lista os componentes específicos do Virabrequim Russo FAW and flywheel assembly. Correct identification of these parts is essential for ensuring engine balance and sealing integrity during overhaul procedures for the CA3250P66K24L1TE5Z.

| Não. |

Número da peça |

Nome da peça |

Quantidade |

| 1 |

1005048-53D |

Damper Bolt |

8 |

| 2 |

Q1862040 (HB) |

Parafuso de flange hexadecimal – Enlarged Series |

1 |

| 3 |

1005046A81D |

Poly-V Belt Pulley |

1 |

| 4 |

1005195-81D |

Conjunto de amortecedor de óleo de silicone |

1 |

| 5 |

Q1841020 |

Parafuso de flange hexadecimal (Haste Grossa/Padrão) |

12 |

| 6 |

1005050-53D |

Crankshaft Front Oil Seal Assembly |

1 |

| 7 |

1005015-81D |

Crankshaft Oil Pump Gear Assembly |

1 |

| 8 |

1005037-81D |

Equipamento de tempo do eixo de manivela |

1 |

| 9 |

1005060-53D |

Crankshaft Rear Oil Seal Assembly |

1 |

| 10 |

1005031-29D |

Drive Gear and Flywheel Dowel Pin |

1 |

| 11 |

1005120-73D |

Conjunto do volante |

1 |

| 12 |

60305 |

Input Shaft Front Bearing |

1 |

| 13 |

1005071-81D |

Flywheel Bolt |

12 |

Diagnostic Protocols for the Rotating Assembly

Inspecionando o Virabrequim Russo FAW assembly requires attention to detail. O Conjunto de amortecedor de óleo de silicone should be checked visually for leaks. Any sign of viscous fluid leaking from the damper housing indicates failure; a compromised damper will allow dangerous harmonic vibrations that can snap the crankshaft. Adicionalmente, check the rubber seal area for cracks, though the internal fluid is the primary damping medium.

Oil leaks at the front or rear of the engine often point to failure of the Crankshaft Front Oil Seal Assembly or Rear Seal. Em climas frios, check if the breather system is blocked by ice, as high crankcase pressure can force oil past even a healthy seal. If the seals are replaced, ensure the crankshaft journal surface is polished and free of burrs to prevent immediate damage to the new seal lip.

Finalmente, inspecionar o Conjunto do volante friction surface during clutch replacements. Heat checking or cracks indicate overloading. Certifique-se de que Flywheel Bolts are torqued to specification using a calibrated wrench. Loose bolts can cause vibration that mimics engine bearing failure. Always check the Input Shaft Front Bearing for smooth rotation; a gritty feel necessitates replacement to protect the transmission input shaft.

Conclusão: The Foundation of Engine Life

O Virabrequim Russo FAW is the fundamental component upon which the entire engine’s reliability is built. It manages the brutal forces of combustion and converts them into usable power. Every component attached to it, do Conjunto de amortecedor de óleo de silicone para o Conjunto do volante, plays a vital role in balancing these forces and ensuring smooth operation.

For fleet owners operating in the unforgiving environment of the Russian Federation, using genuine FAW parts is the only way to guarantee longevity. Aftermarket seals may freeze and leak, and generic dampers may fail to arrest harmonic vibrations. Ao manter o Virabrequim Russo FAW with OEM components, you ensure that your CA3250P66K24L1TE5Z dump truck remains a reliable asset capable of conquering the toughest winter roads.

Embalagem e Logística

Peças FAW, incluindo o conjunto do bloco de cilindros, são embalados com cuidado para garantir uma entrega segura. Cada componente é protegido por materiais de proteção para evitar danos durante o transporte. A rede logística garante envios pontuais em todo o mundo, apoiando operações de manutenção eficientes. Abaixo está uma imagem ilustrando a embalagem padrão para peças de caminhão FAW, mostrando a atenção aos detalhes no manuseio e armazenamento.

Esta abordagem de embalagem minimiza o risco de corrosão ou danos por impacto, garantindo que peças como o conjunto do bloco de cilindros FAW cheguem em perfeitas condições. Os clientes podem confiar na logística da FAW para obter qualidade e confiabilidade consistentes.