Bem-vindo a este guia técnico crítico sobre o Sensor de nitrogênio-oxigênio FAW e conjunto lógico de sensor de alta temperatura (Conjunto 551). Este é o conjunto completo de eletrônicos “olhos e ouvidos” para o sistema de pós-tratamento de emissões no FAW Jiefang CA4251P66K24T1A3E5 6×4 trator semirreboque diesel.

O Sensor de nitrogênio-oxigênio FAW e conjunto lógico de sensor de alta temperatura é o “lógica” hub para a Redução Catalítica Seletiva do caminhão (Scr) sistema. Seus componentes, o 'Conjunto do sensor de nitrogênio-oxigênio’ (3602510-51B) e o 'Conjunto do sensor de alta temperatura’ (3602505-51B-C00), fornecem os dados em tempo real que o computador do motor (ECU) precisa gerenciar com precisão a injeção de fluido de escapamento diesel (DEF/Ureia) e controlar as emissões.

Este guia detalhado é um recurso essencial para técnicos profissionais de diesel e especialistas em peças. Vamos desconstruir todo Sensor de nitrogênio-oxigênio FAW e conjunto lógico de sensor de alta temperatura em seu 7 componentes reparáveis, explicando a crítica “lógica” de cada sensor, sua função no sistema SCR, e os suportes de montagem que os protegem.

O Sensor de nitrogênio-oxigênio FAW e conjunto lógico de sensor de alta temperatura é o “cérebro” do moderno sistema de emissões. Este sistema é conhecido como **Redução Catalítica Seletiva (Scr)**. Seu único objetivo é converter óxidos de nitrogênio prejudiciais (NOx)—um componente importante da poluição atmosférica e da chuva ácida—em nitrogênio inofensivo (N2) e água (H2O).

Esta reação química é obtida pela injeção de fluido de escapamento diesel (DEF), uma solução de uréia e água, no fluxo de exaustão quente pouco antes de entrar em um catalisador especial (o catalisador SCR, parte da Assembleia 127).

É aqui que “lógica” do Sensor de nitrogênio-oxigênio FAW e conjunto lógico de sensor de alta temperatura entra. A Unidade de Controle do Motor do caminhão (ECU) deve saber a quantidade *exata* de DEF a ser injetada.

O Sensor de nitrogênio-oxigênio FAW e conjunto lógico de sensor de alta temperatura fornece o “circuito fechado” feedback que a ECU precisa para injetar o perfeito, quantidade estequiométrica de DEF. É a entrada sensorial que torna possível esta reação química precisa..

O 'Conjunto do sensor de nitrogênio-oxigênio’ (3602510-51B) é a parte mais complexa e crítica do Sensor de nitrogênio-oxigênio FAW e conjunto lógico de sensor de alta temperatura. Este não é um sensor simples; é um sofisticado, dispositivo cerâmico multicelular com seu próprio módulo de controle integrado.

**Função:** Este sensor é normalmente instalado *após* o catalisador SCR. Isso é “lógica” é ser o “boletim escolar” para todo o sistema de pós-tratamento. Ele mede com precisão as partes por milhão restantes (PPM) de óxidos de nitrogênio (NOx) no gás de exaustão *depois* de ter sido tratado.

Este sensor fornece o resultado final “opinião” no sistema de malha fechada. A ECU monitora constantemente as leituras deste sensor. Se detectar que os níveis de NOx estão começando a aumentar, isto “sabe” que sua atual taxa de injeção de DEF é insuficiente, e aumentará precisamente a injeção “aparar” até que o sensor informe que os níveis de NOx voltaram a quase zero.

**Falha:** O sensor NOx é um componente de alto desgaste no Sensor de nitrogênio-oxigênio FAW e conjunto lógico de sensor de alta temperatura. Ele vive em um ambiente extremamente quente, ambiente de alta vibração e é sensível à contaminação por combustível ou DEF de baixa qualidade. Um sensor de NOx com falha é uma falha crítica. A ECU perde a sua “olhos,” não pode mais verificar as emissões, e irá desencadear imediatamente um “Verifique o motor” luz, a “Modo manco” (redução severa da potência do motor), e registrará uma falha no sistema de controle de emissões. O Sensor de nitrogênio-oxigênio FAW e conjunto lógico de sensor de alta temperatura está completamente desativado sem este sensor.

O 'Conjunto do sensor de alta temperatura’ (3602505-51B-C00) é o segundo “lógica” componente do Sensor de nitrogênio-oxigênio FAW e conjunto lógico de sensor de alta temperatura. Este é um termistor ou termopar de alta qualidade projetado para suportar temperaturas extremas de exaustão (acima de 800°C).

**Função (Lógica SCR):** A reação química do DEF (ureia) a conversão de NOx é altamente dependente da temperatura. Só funciona de forma eficiente dentro de uma temperatura específica “janela” (Por exemplo, 200°C a 450 °C). O “lógica” deste sensor é informar à ECU quando é seguro começar a injetar DEF. Se a ECU injeta DEF em um “frio” (abaixo de 200°C) sistema de exaustão, a uréia não se converterá em amônia; simplesmente cristalizará, formando duro, depósitos brancos (“endurecimento”) que bloqueará o catalisador SCR, uma falha catastrófica e cara. Este sensor no Sensor de nitrogênio-oxigênio FAW e conjunto lógico de sensor de alta temperatura impede isso.

**Função (Lógica DPF):** Este sensor também fornece a resposta crítica “lógica” para **regeneração DPF**. O filtro de partículas diesel (DPF) retém fuligem, e deve ser limpo periodicamente por “regenerando” (queimando a fuligem a mais de 600°C). A ECU depende deste sensor para monitorar a temperatura do DPF, garantindo um “regenerar” é bem sucedido e seguro (Ou seja,, não esquenta o suficiente para derreter o catalisador). Este é um propósito duplo, componente essencial do Sensor de nitrogênio-oxigênio FAW e conjunto lógico de sensor de alta temperatura.

Os delicados sensores eletrônicos do Sensor de nitrogênio-oxigênio FAW e conjunto lógico de sensor de alta temperatura não pode simplesmente ser deixado pendurado. Eles devem ser rigidamente fixados e sua fiação protegida contra derretimento ou atrito.

**'Suporte superior do sensor de nitrogênio-oxigênio’ (3602546-81C):** Este colchete é “lógica” é proteção. O sensor NOx (3602510-51B) é um dispositivo de duas partes: o “sonda” que é aparafusado no tubo de escape, e um “módulo de controle” (uma pequena caixa preta) conectado por um fio. Este suporte foi projetado para montar o *módulo de controle* com segurança na estrutura do chassi, longe do calor extremo do escapamento.

**'Suporte do chicote elétrico principal’ (3724426-68V):** Este suporte é usado para fixar o chicote elétrico principal do Sensor de nitrogênio-oxigênio FAW e conjunto lógico de sensor de alta temperatura, evitando que os fios esfreguem contra o chassi (o que causaria um curto) ou pendurado perto do tubo de escape quente (que os derreteria).

Esses suportes são fixados com 'parafusos de flange sextavados’ (Q1840616) e 'Porcas de flange sextavadas’ (CQ39606). O “mesa” O design é uma lógica resistente à vibração que evita que os fixadores se soltem. Finalmente, os dois ‘laços zip de plástico’ (T67417246) são uma parte simples, mas crítica do Sensor de nitrogênio-oxigênio FAW e conjunto lógico de sensor de alta temperatura, usado para fornecer o final, fixação segura para os fios do sensor.

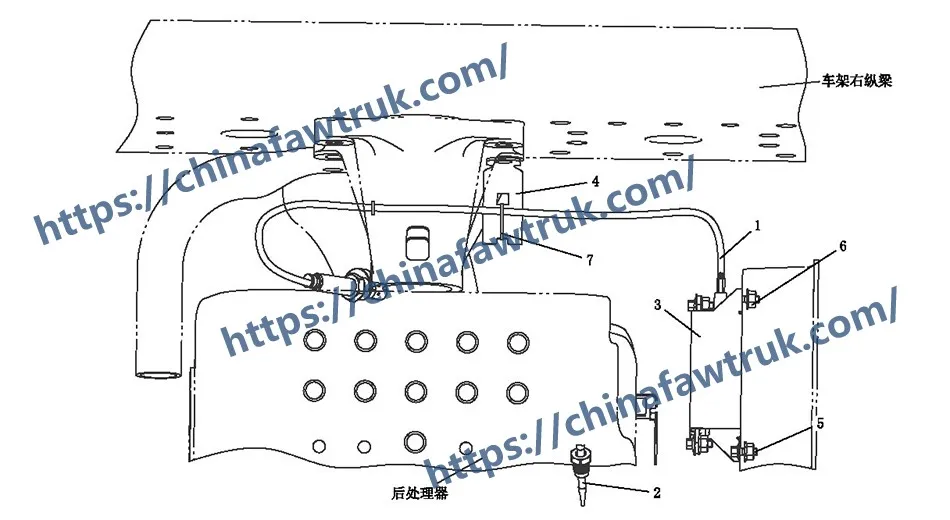

A tabela a seguir fornece o completo, detalhamento de todos 7 componentes identificados no 'Sensor de nitrogênio-oxigênio e conjunto lógico de sensor de alta temperatura’ (551) diagrama para o trator FAW CA4251P66K24T1A3E5.

| Marca | Parte não. | Nome da peça | Quantidade |

|---|---|---|---|

| 1 | 3602510-51B | Conjunto do sensor de nitrogênio-oxigênio | 1 |

| 2 | 3602505-51B-C00 | Conjunto de sensor de alta temperatura | 1 |

| 3 | 3602546-81C | Suporte superior do sensor de nitrogênio-oxigênio | 1 |

| 4 | 3724426-68V | Suporte do chicote elétrico principal | 1 |

| 5 | Q1840616 | Parafuso de flange sextavado, haste grossa (Tipo padrão) | 4 |

| 6 | CQ39606 | Porca flangeada sextavada | 4 |

| 7 | T67417246 | Gravata plástica com zíper | 2 |

As especificações para o Sensor de nitrogênio-oxigênio FAW e conjunto lógico de sensor de alta temperatura são definidos por sua função como “cérebro” do sistema de pós-tratamento de emissões.

| Aplicação em veículos | FAW Jiefang CA4251P66K24T1A3E5 6×4 Trator |

| Grupo de Componentes | Sensor de nitrogênio-oxigênio FAW e conjunto lógico de sensor de alta temperatura |

| Sensor NOx Principal P/N | 3602510-51B |

| Sensor de temperatura principal P/N | 3602505-51B-C00 |

| Tipo de sistema | Controle de Pós-Tratamento de Emissões (Scr / DPF) |

| Lógica Primária | Feedback de circuito fechado para ECU |

| Suportes de sensores | 3602546-81C (NOx), 3724426-68V (Aproveitar) |

| Função Primária | Para medir o conteúdo de NOx e a temperatura de exaustão, permitindo que a ECU controle com precisão a injeção de DEF e a regeneração do DPF. |

Peças FAW, incluindo o conjunto do bloco de cilindros, são embalados com cuidado para garantir uma entrega segura. Cada componente é protegido por materiais de proteção para evitar danos durante o transporte. A rede logística garante envios pontuais em todo o mundo, apoiando operações de manutenção eficientes. Abaixo está uma imagem ilustrando a embalagem padrão para peças de caminhão FAW, mostrando a atenção aos detalhes no manuseio e armazenamento.

Esta abordagem de embalagem minimiza o risco de corrosão ou danos por impacto, garantindo que peças como o conjunto do bloco de cilindros FAW cheguem em perfeitas condições. Os clientes podem confiar na logística da FAW para obter qualidade e confiabilidade consistentes.