Welcome to this critical technical guide on the FAW Nitrogen-Oxygen Sensor And High-Temperature Sensor Logic Assembly (Assembly 551). This is the complete set of electronic “eyes and ears” for the emissions after-treatment system on the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor.

The FAW Nitrogen-Oxygen Sensor And High-Temperature Sensor Logic Assembly is the “logic” hub for the truck’s Selective Catalytic Reduction (SCR) system. Its components, the ‘Nitrogen-oxygen sensor assembly’ (3602510-51B) and the ‘High-temperature sensor assembly’ (3602505-51B-C00), provide the real-time data that the engine’s computer (ECU) needs to precisely manage the injection of Diesel Exhaust Fluid (DEF/Urea) and control emissions.

This in-depth guide is an essential resource for professional diesel technicians and parts specialists. We will deconstruct the entire FAW Nitrogen-Oxygen Sensor And High-Temperature Sensor Logic Assembly into its 7 serviceable components, explaining the critical “logic” of each sensor, their function in the SCR system, and the mounting brackets that protect them.

The FAW Nitrogen-Oxygen Sensor And High-Temperature Sensor Logic Assembly is the “brain” of the modern emissions system. This system is known as **Selective Catalytic Reduction (SCR)**. Its sole purpose is to convert harmful Nitrogen Oxides (NOx)—a major component of smog and acid rain—into harmless nitrogen (N2) and water (H2O).

This chemical reaction is achieved by injecting Diesel Exhaust Fluid (DEF), a solution of urea and water, into the hot exhaust stream just before it enters a special catalyst (the SCR catalyst, part of Assembly 127).

This is where the “logic” of the FAW Nitrogen-Oxygen Sensor And High-Temperature Sensor Logic Assembly comes in. The truck’s Engine Control Unit (ECU) must know the *exact* amount of DEF to inject.

The FAW Nitrogen-Oxygen Sensor And High-Temperature Sensor Logic Assembly provides the “closed-loop” feedback the ECU needs to inject the perfect, stoichiometric amount of DEF. It is the sensory input that makes this precise chemical reaction possible.

The ‘Nitrogen-oxygen sensor assembly’ (3602510-51B) is the most complex and critical part of the FAW Nitrogen-Oxygen Sensor And High-Temperature Sensor Logic Assembly. This is not a simple sensor; it is a sophisticated, multi-cell ceramic device with its own integrated control module.

**Function:** This sensor is typically installed *after* the SCR catalyst. Its “logic” is to be the “report card” for the entire after-treatment system. It precisely measures the remaining parts-per-million (PPM) of Nitrogen Oxides (NOx) in the exhaust gas *after* it has been treated.

This sensor provides the final “feedback” in the closed-loop system. The ECU constantly monitors this sensor’s readings. If it detects that NOx levels are starting to creep up, it “knows” that its current DEF injection rate is insufficient, and it will precisely increase the injection “trim” until the sensor reports that NOx levels are back to near-zero.

**Failure:** The NOx sensor is a high-wear component in the FAW Nitrogen-Oxygen Sensor And High-Temperature Sensor Logic Assembly. It lives in an extremely hot, high-vibration environment and is sensitive to contamination from poor-quality fuel or DEF. A failed NOx sensor is a critical fault. The ECU loses its “eyes,” can no longer verify the emissions, and will immediately trigger a “Check Engine” light, a “Limp Mode” (severe engine power reduction), and will log a fault for the emissions-control system. The FAW Nitrogen-Oxygen Sensor And High-Temperature Sensor Logic Assembly is completely disabled without this sensor.

The ‘High-temperature sensor assembly’ (3602505-51B-C00) is the second “logic” component of the FAW Nitrogen-Oxygen Sensor And High-Temperature Sensor Logic Assembly. This is a high-grade thermistor or thermocouple designed to withstand extreme exhaust temperatures (over 800°C).

**Function (SCR Logic):** The chemical reaction of DEF (urea) converting NOx is highly temperature-dependent. It only works efficiently within a specific temperature “window” (e.g., 200°C to 450°C). The “logic” of this sensor is to tell the ECU when it is safe to start injecting DEF. If the ECU injects DEF into a “cold” (below 200°C) exhaust system, the urea will not convert to ammonia; it will simply crystallize, forming hard, white deposits (“caking”) that will block the SCR catalyst, a catastrophic and expensive failure. This sensor in the FAW Nitrogen-Oxygen Sensor And High-Temperature Sensor Logic Assembly prevents that.

**Function (DPF Logic):** This sensor also provides the critical “logic” for **DPF Regeneration**. The Diesel Particulate Filter (DPF) traps soot, and it must be periodically cleaned out by “regenerating” (burning the soot at over 600°C). The ECU relies on this sensor to monitor the DPF’s temperature, ensuring a “regen” is both successful and safe (i.e., it doesn’t get hot enough to melt the catalyst). This is a dual-purpose, essential component of the FAW Nitrogen-Oxygen Sensor And High-Temperature Sensor Logic Assembly.

The delicate electronic sensors in the FAW Nitrogen-Oxygen Sensor And High-Temperature Sensor Logic Assembly cannot simply be left to hang. They must be rigidly secured and their wiring protected from melting or chafing.

**’Nitrogen-oxygen sensor upper bracket’ (3602546-81W):** This bracket’s “logic” is protection. The NOx sensor (3602510-51B) is a two-part device: the “probe” that screws into the exhaust pipe, and a “control module” (a small black box) connected by a wire. This bracket is designed to mount the *control module* safely on the chassis frame, away from the extreme heat of the exhaust.

**’Main wiring harness bracket’ (3724426-68V):** This bracket is used to secure the main wiring harness for the FAW Nitrogen-Oxygen Sensor And High-Temperature Sensor Logic Assembly, preventing the wires from rubbing against the chassis (which would cause a short) or dangling near the hot exhaust pipe (which would melt them).

These brackets are secured with ‘Hex flange bolts’ (Q1840616) and ‘Hex flange nuts’ (CQ39606). The “flange” design is a vibration-resistant logic that prevents the fasteners from loosening. Finally, the two ‘Plastic zip ties’ (T67417246) are a simple but critical part of the FAW Nitrogen-Oxygen Sensor And High-Temperature Sensor Logic Assembly, used to provide the final, secure fastening for the sensor wires.

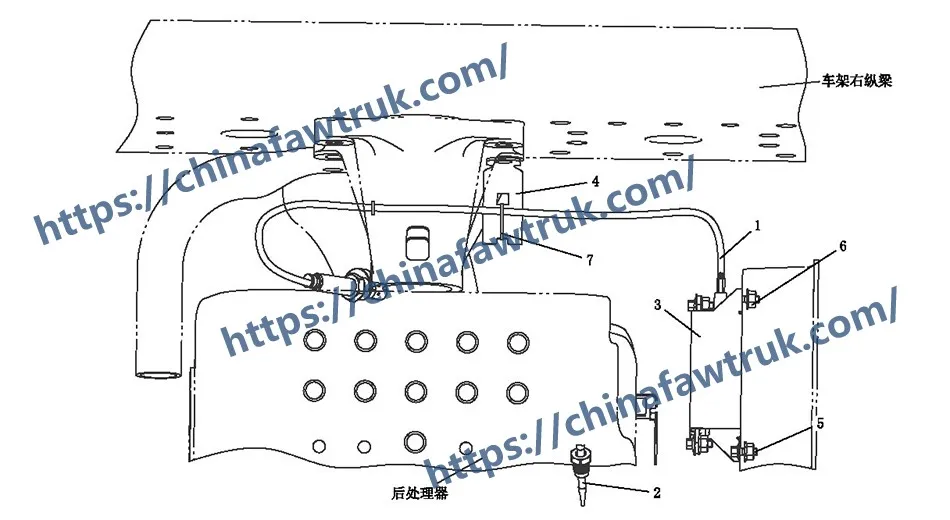

The following table provides the complete, detailed breakdown of all 7 components identified in the ‘Nitrogen-Oxygen Sensor And High-Temperature Sensor Logic Assembly’ (551) diagram for the FAW CA4251P66K24T1A3E5 tractor.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 3602510-51B | Nitrogen-oxygen sensor assembly | 1 |

| 2 | 3602505-51B-C00 | High-temperature sensor assembly | 1 |

| 3 | 3602546-81W | Nitrogen-oxygen sensor upper bracket | 1 |

| 4 | 3724426-68V | Main wiring harness bracket | 1 |

| 5 | Q1840616 | Hex flange bolt, coarse rod (Standard Type) | 4 |

| 6 | CQ39606 | Hex flange nut | 4 |

| 7 | T67417246 | Plastic zip tie | 2 |

The specifications for the FAW Nitrogen-Oxygen Sensor And High-Temperature Sensor Logic Assembly are defined by its function as the “brain” of the emissions after-treatment system.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | FAW Nitrogen-Oxygen Sensor And High-Temperature Sensor Logic Assembly |

| Main NOx Sensor P/N | 3602510-51B |

| Main Temp Sensor P/N | 3602505-51B-C00 |

| System Type | Emissions After-Treatment Control (SCR / DPF) |

| Primary Logic | Closed-Loop Feedback for ECU |

| Sensor Brackets | 3602546-81W (NOx), 3724426-68V (Harness) |

| Primary Function | To measure NOx content and Exhaust Temperature, allowing the ECU to precisely control DEF injection and DPF regeneration. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.