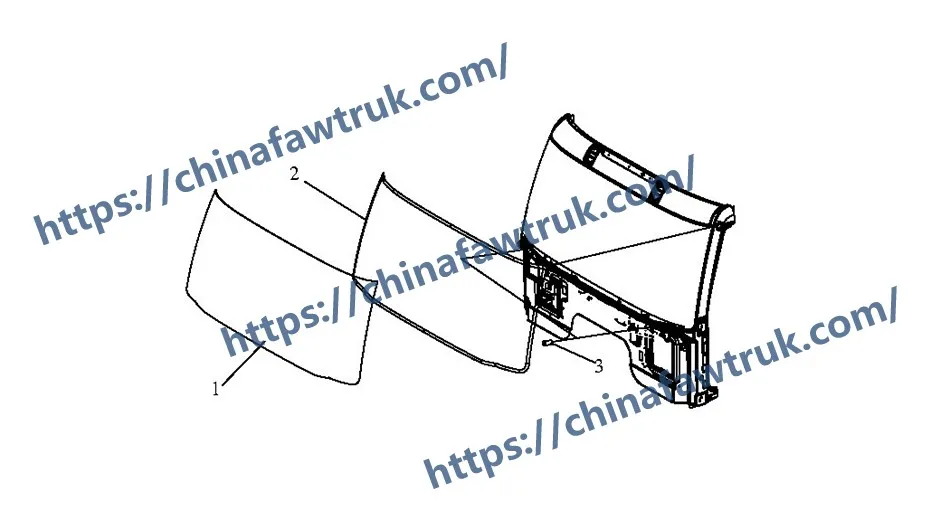

Este é um guia técnico completo para o Pára-brisas FAW J6P montagem para o FAW Jiefang CA3250P66K2L1T1E 6×4 caminhão despejando. Esta desconstrução analisa o 3 tipos de componentes primários, detailing the critical glass panel, the necessary sealing strip, and the specialized limit sleeves that ensure the integrity of the forward view.

O Pára-brisas FAW J6P is more than just a piece of glass; it is a critical safety and structural component of the cab. In a commercial vehicle, the front window must be laminated safety glass, designed to remain intact upon impact, thereby protecting the occupants and preventing foreign objects from entering the cab. The large viewing area provided by this glass panel is essential for the driver to maintain situational awareness in complex construction and road environments.

The assembly’s apparent simplicity—just three primary part types—belies the engineering precision required for installation. The integrity of the entire forward visual system relies entirely on the quality of the glass itself, the longevity of the rubber seal, and the precise fitment of the limit sleeves. Failure of the sealing system can lead to water intrusion, barulho do vento, and eventual corrosion of the cab structure around the glass aperture. This deconstruction will analyze the composition and installation logic of the three key components of the **FAW J6P Windscreen** assembly.

This component is the primary functional element of the windscreen system. Its material composition is strictly regulated for maximum safety and optical clarity, which directly impacts driver performance.

1. Componente: ‘Front Windscreen Glass’ (5206011-A01) – Quantidade 1

Esse (Comp. 1) is the actual large glass panel. O Safety Glass Logic dictates this must be laminated glass, consisting of two layers of glass bonded together with a layer of polyvinyl butyral (PVB) film. This construction ensures that if the glass is fractured, the pieces remain adhered to the PVB layer, preventing sharp shards from flying and maintaining structural integrity. The optical quality of the glass is critical to prevent distortion that could cause driver fatigue or impaired judgment, especially during night driving.

O grande, curved shape of the entire front window assembly is precisely engineered to provide maximum frontal and peripheral visibility, a key factor in the safety rating of the cab. This large glass area also contributes significantly to the cab’s overall torsional stiffness. Any deviation from the OEM specifications for the glass panel can compromise the integrity of the entire cab shell, levando ao fracasso.

Proper replacement of the windscreen requires specialized lifting equipment and strict adherence to specific bonding or sealing procedures. The front glass plays a structural role, meaning that an amateur replacement procedure can severely weaken the cab structure.

This group of components provides the critical environmental seal around the perimeter of the front window. Their function is non-negotiable for cab protection and acoustic comfort.

1. Componente: ‘Front Windscreen Seal Strip’ (5206022-A01) – Quantidade 1

Esse (Comp. 2) is the primary weather-stripping or rubber gasket. O Water Barrier Logic dictates that this flexible rubber or polymer strip is designed to fill the gap between the glass panel (Comp. 1) and the metal cab aperture. This prevents water, pó, and wind noise from entering the cab. Damage or hardening of the seal strip is the most common cause of leaks and cabin noise. The installation of this strip is often a high-precision task, requiring adhesive bonding agents to ensure the seal maintains its integrity under dynamic stress.

2. Componente: ‘Limit Sleeve – Front Windscreen’ (5206036-A01) – Quantidade 2

Esse (Comp. 3) is a specialized spacer or grommet. Two of these are used, strategically placed around the glass aperture. O Lógica de Posicionamento é crítico: these sleeves ensure the glass panel is correctly positioned within the cab frame before the final seal is applied. This sets the perfect gap around the glass, allowing the seal strip (Comp. 2) to compress uniformly. Incorrect placement of these limit sleeves can lead to uneven pressure on the front glass, causing stress cracks or poor sealing.

The overall acoustic performance of the front window relies on the seamless cooperation between the glass, the seal strip, and the limit sleeves. These components work together to provide a quiet, seco, and structurally sound cab environment for the driver.

The installation and maintenance protocols for the windscreen are as critical as the components themselves, given the safety implications of a failed front window.

1. Cab Structural Reinforcement

The cab structure around the front window aperture is heavily reinforced. O A-Pillar Logic dictates that the metal supports on either side of the glass must be capable of bearing significant load in the event of a rollover. A correctly installed front window actually contributes significantly to the torsional stiffness of the cab. This structural integration is achieved through the use of high-modulus polyurethane adhesive (not listed in the BOM but required for installation) which rigidly bonds the glass to the cab frame, transforming the glass into a structural member.

2. Failure and Replacement Consequences

A common failure mode for the front glass is cracking due to stone chips or localized pressure points from an uneven frame. If a crack occurs, the safety feature of the laminated glass prevents total shattering. No entanto, the integrity is compromised, and the entire panel must be replaced immediately. Using improper seals or failing to utilize the limit sleeves (Comp. 3) during replacement can lead to localized stress points, which could cause a newly installed window to crack prematurely under normal road vibration.

3. Environmental Factors in Heavy-Duty Use

In a dump truck operating on dusty, uneven terrain, os selos (Comp. 2) of the front window are subjected to extremes. The constant chassis flex and vibration necessitate high-quality, durable sealing material. Regular inspection of the seal strip for cracks, shrinkage, or gaps is essential preventive maintenance. Water ingress caused by a failed seal can damage cab electronics located beneath the dashboard, leading to expensive secondary failures in the vehicle’s electrical system.

The continued service life of the vehicle depends heavily on the robustness of every major component. The entire front window system plays its role as a structural, segurança, and environmental component for the driver. Every single element of the front window assembly must meet the precise OEM specifications to deliver reliable performance over the vehicle’s entire operational life cycle.

A tabela a seguir fornece o completo, detalhamento de todos 3 tipos de componentes no Pára-brisas FAW J6P montagem para o FAW Jiefang CA3250P66K2L1T1E 6×4 caminhão despejando. Esta lista é essencial para solicitar peças de reposição e realizar um serviço completo do Pára-brisas FAW J6P.

| Marca | Parte não. | Nome da peça | Quantidade |

|---|---|---|---|

| 1 | 5206011-A01 | Vidro do pára-brisa dianteiro | 1 |

| 2 | 5206022-A01 | Front Windscreen Seal Strip | 1 |

| 3 | 5206036-A01 | Manga Limite – Front Windscreen | 2 |

As especificações para o Pára-brisas FAW J6P are defined by its laminated safety glass, ensuring both driver visibility and structural integrity of the cab structure.

| Aplicação em veículos | FAW Jiefang CA3250P66K2L1T1E 6×4 Caminhão basculante |

| Grupo de sistemas | Pára-brisas FAW J6P |

| Tipo de vidro | Laminated Safety Glass (Structural Component) |

| Glass Panel P/N | 5206011-A01 |

| Componente de vedação | ‘Front Windscreen Seal Strip’ (5206022-A01) |

| Alignment Component | ‘Limit Sleeve – Front Windscreen’ (5206036-A01) |

| Função Primária | Driver visibility and cab torsional stiffness |

| Total de tipos de componentes | 3 |

| Sistema Associado | Exterior da cabine / Safety Barrier. O Pára-brisas FAW J6P is critical for forward view. |

Peças FAW, incluindo o conjunto do bloco de cilindros, são embalados com cuidado para garantir uma entrega segura. Cada componente é protegido por materiais de proteção para evitar danos durante o transporte. A rede logística garante envios pontuais em todo o mundo, apoiando operações de manutenção eficientes. Abaixo está uma imagem ilustrando a embalagem padrão para peças de caminhão FAW, mostrando a atenção aos detalhes no manuseio e armazenamento.

Esta abordagem de embalagem minimiza o risco de corrosão ou danos por impacto, garantindo que peças como o conjunto do bloco de cilindros FAW cheguem em perfeitas condições. Os clientes podem confiar na logística da FAW para obter qualidade e confiabilidade consistentes.