Welcome to this critical technical guide on the FAW Rear Wheel Hub Logic Assembly Steel Wheel (Part No. 3104G24DA6T). This is the complete, load-bearing “wheel-end” system for the rear *drive axles* of the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor. This assembly is the final link in transmitting torque to the road.

The FAW Rear Wheel Hub Logic Assembly Steel Wheel is a “unitized” hub designed for a heavy-duty drive axle. Its “logic” is to provide a low-friction, high-strength rotating mount for the “dual-wheel” **Steel Wheel** setup, while also being internally splined to accept the half-shaft (axle shaft) from the differential.

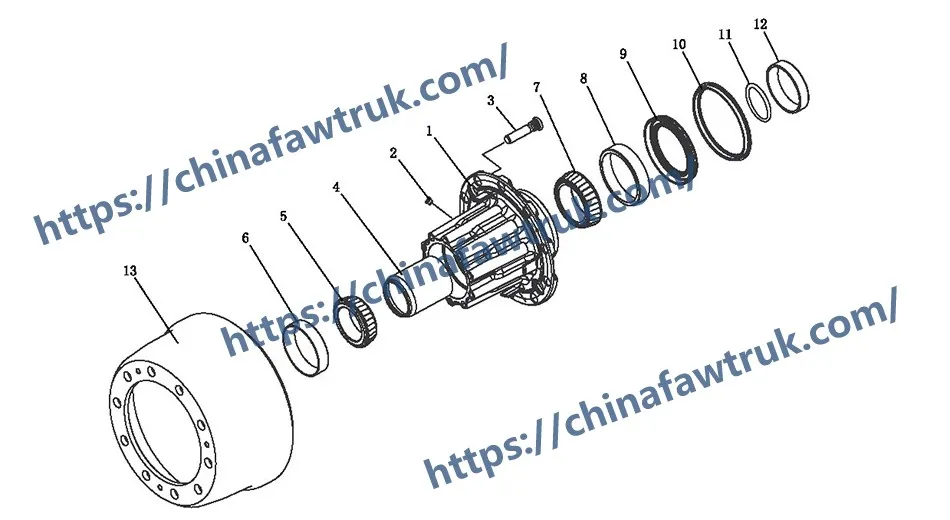

This in-depth guide is an essential resource for professional driveline technicians and fleet managers. We will deconstruct the entire FAW Rear Wheel Hub Logic Assembly Steel Wheel into its 13 serviceable components, including the main ‘Hub’ (10045312), the ConMet ‘Bearings’ (Inner and Outer), the ‘Rear brake drum’ (3502571-A6T), and the critical ‘ABS ring’ (10041090).

The heart of the FAW Rear Wheel Hub Logic Assembly Steel Wheel is the ‘Hub’ (10045312). This is the main structural component, a massive, precision-machined casting of ductile iron. This “drive hub” is fundamentally different from the “steer hub” on the front axle.

While both hubs house the bearings, this rear hub has one additional, critical feature: it is internally splined. These splines are designed to engage with the splines of the ‘Half-Shaft’ (axle shaft, see Assembly 328 or 400). This is how the FAW Rear Wheel Hub Logic Assembly Steel Wheel receives rotational torque from the differential, which it then transmits to the wheels via the 10 ‘Wheel studs’ (10001399).

The “Steel Wheel” designation of the FAW Rear Wheel Hub Logic Assembly Steel Wheel indicates this hub is designed for the high-clamping-force and durability requirements of steel dual-wheels (“duallies”), which are the standard for maximum load capacity on a drive axle. This assembly also provides the mounting face for the ‘Rear brake drum’ (3502571-A6T).

The “logic” of this specific FAW Rear Wheel Hub Logic Assembly Steel Wheel lies in its advanced, “unitized” bearing system. The parts are all sourced from ConMet (康迈公司), a leader in hub-end technology. The key components are:

In a traditional FAW Rear Wheel Hub Logic Assembly Steel Wheel, these two bearings are “loose.” A technician must tighten the main axle nut to a precise, *low-torque* “preload” specification, usually while spinning the hub. This process is difficult, time-consuming, and a common source of errors (over-tightening leads to bearing seizure; under-tightening leads to “wobble” and failure).

This ConMet system’s “logic” is different. The ‘Bearing spacer’ is a precision-ground, “matched” spacer that is engineered to be the *exact* width needed to set the perfect preload. The technician installs the inner bearing, the spacer, and the outer bearing. Then, they simply tighten the main axle nut to a very *high*, fixed torque. The spacer absorbs this torque, automatically setting the bearing preload to the perfect factory specification. This eliminates guesswork, dramatically increases bearing life, and simplifies service for the FAW Rear Wheel Hub Logic Assembly Steel Wheel.

The bearings in the FAW Rear Wheel Hub Logic Assembly Steel Wheel are lubricated by heavy-duty axle/gear oil. The ‘Oil seal (Cummins)’ (10080112) is the single most critical component for keeping this oil *in* and keeping water, dust, and road grime *out*.

This is a high-tech, multi-lip radial shaft seal. It is pressed into the back of the ‘Hub’ (10045312), and its flexible, spring-loaded lips ride on the ‘Seal seat’ (3104044-A6T), a polished “wear ring” on the main axle housing.

A failure of this one seal in the FAW Rear Wheel Hub Logic Assembly Steel Wheel is a catastrophic event. If it leaks oil *out*, the ‘Inner’ and ‘Outer’ bearings will run dry, overheat, and seize, which can cause the entire wheel to lock up or detach from the vehicle. If it leaks *in*, water will contaminate the oil, causing the bearings to rust and “spall” (flake apart). This is why the ‘O-ring’ (3104066-A6T-C00) is also used to ensure the ‘Seal seat’ is locked in place.

The ‘Oil filler plug’ (10036508) is the “hub cap” or “oil plug” that seals the *outer* end of the FAW Rear Wheel Hub Logic Assembly Steel Wheel. This component (often with a clear “sight glass”) allows a technician to visually inspect the oil level and condition without having to disassemble the hub, which is a key service “logic.”

The “logic” of the FAW Rear Wheel Hub Logic Assembly Steel Wheel‘s braking system is contained in the ‘ABS ring (Cummins)’ (10041090). This is the “tone ring” for the Anti-lock Braking System.

This is a “toothed” metal ring that is pressed onto the ‘Hub’ (10045312). As the wheel rotates, the teeth of this ring fly past the ‘Wheel speed sensor’ (a separate part). This “chopping” of the magnetic field creates a digital pulse, which is sent to the truck’s ABS computer.

The ABS computer uses this pulse to know the exact rotational speed of the wheel. If the driver “panic brakes” and the computer sees this ring suddenly *stop* (indicating a locked wheel), it will instantly “pump” the ‘Rear brake drum’ (3502571-A6T), allowing the wheel to regain traction. This “anti-lock” logic is a critical safety feature, and it is entirely dependent on the integrity of this ‘ABS ring’ within the FAW Rear Wheel Hub Logic Assembly Steel Wheel.

The following table provides the complete, detailed breakdown of all 13 components identified in the ‘Rear Wheel Hub Logic Assembly Steel Wheel’ (524) diagram for the FAW CA4251P66K24T1A3E5 tractor.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 3104G24DA6T | Rear wheel hub logic assembly (ConMet steel wheel) | 1 | |

| 1 | 10045312 | Hub (ConMet company part number) | 1 |

| 2 | 10036508 | Oil filler plug (ConMet company part number) | 1 |

| 3 | 10001400 | Wheel stud (ConMet company part number) | 10 |

| 4 | 10045316 | Bearing spacer (ConMet company part number) | 1 |

| 5 | 10045759 | Inner bearing (ConMet non-standard bearing 33019) | 1 |

| 6 | 10045483 | Outer bearing (ConMet non-standard bearing 33019) | 1 |

| 7 | 10045314 | Inner bearing (ConMet non-standard bearing 33021) | 1 |

| 8 | 10045313 | Outer bearing (ConMet non-standard bearing 33021) | 1 |

| 9 | 10080112 | Oil seal (ConMet company part number) | 1 |

| 10 | 10041090 | ABS ring (ConMet company part number) | 1 |

| 11 | 3104066-A6T-C00 | O-ring (as-per-sample) | 1 |

| 12 | 3104044-A6T | Seal seat | 1 |

| 13 | 3502571-A6T | Rear brake drum | 1 |

The specifications for the FAW Rear Wheel Hub Logic Assembly Steel Wheel are defined by its function as a unitized, low-friction, high-load wheel-end for a drive axle. This FAW Rear Wheel Hub Logic Assembly Steel Wheel is a key component for safety and performance.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | FAW Rear Wheel Hub Logic Assembly Steel Wheel |

| Main Hub P/N | 10045312 (ConMet) |

| Wheel Type | Steel Wheel (for dual-wheel setup) |

| Bearing System | Unitized, Pre-Set (Tapered Roller) by ConMet |

| Inner Bearing P/N | 10045759 / 10045314 (ConMet) |

| Outer Bearing P/N | 10045483 / 10045313 (ConMet) |

| Spacer P/N | 10045316 (ConMet) |

| Main Seal P/N | 10080112 (ConMet Oil Seal) |

| ABS Logic | 1x ABS Ring (10041090) for Wheel Speed Sensor |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.