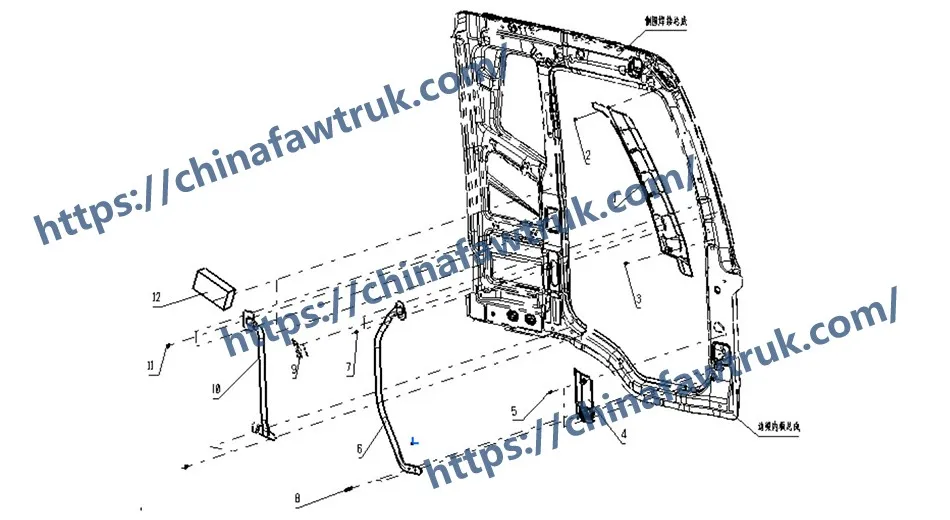

This is a comprehensive technical guide to the FAW J6P Side Cladding and armrest assembly for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This deconstruction analyzes the 17 serviceable component types, detailing the pillar guards, decorative panels, armrests, and mounting hardware that form this critical cab exterior system.

The FAW J6P Side Cladding system is a multi-functional assembly that defines the cab’s profile and provides essential driver access. Its primary function is twofold: first, to act as an aerodynamic shield and protective panel, guarding the cab’s A-pillars and side structure from road debris, mud, and impacts. Second, it serves as the structural foundation for the “upper and lower” armrests (grab handles), which are critical for safe entry and exit from the high-clearance cab.

In a heavy-duty dump truck, the FAW J6P Side Cladding must be exceptionally robust. This deconstruction will analyze the key serviceable components, including the upper pillar guards, the lower decorative panels, the welded armrest assemblies, and the specialized, vibration-resistant fasteners. A properly secured FAW J6P Side Cladding assembly is essential for safety, preventing rattles, and maintaining the cab’s aerodynamic efficiency and professional appearance.

This group of components forms the visible, protective “skin” of the FAW J6P Side Cladding system. These panels are designed to be both aerodynamic and sacrificial, protecting the underlying steel cab structure.

1. Component: ‘Left/Right front pillar upper guard assy’ (5402715-B27, 5402720-B27) – Qty 1 each

This (Comp 1, 2) is the main upper panel of the FAW J6P Side Cladding. The Aerodynamic Logic is that this large, curved panel smooths the airflow from the front of the cab around the A-pillar and side window, reducing wind noise and drag. It also acts as a primary shield, deflecting rain and debris away from the driver’s side window to maintain visibility.

2. Component: ‘Left/Right front pillar lower decorative panel’ (5302771-A01, 5302772-A01) – Qty 1 each

This (Comp 5, 6) is the lower panel that continues the line of the FAW J6P Side Cladding down towards the cab steps. The Aesthetic & Protective Logic is that this “decorative panel” serves to create a finished, integrated look while also acting as a sacrificial scuff panel, protecting the painted cab body from boot marks and stone chips.

These panels are typically made from a durable, UV-resistant ABS polymer. They are secured with specialized ‘Cross recessed pan head screw assy’ (Comp 3, 7), which are designed to sit flush and provide a secure, vibration-free fit. A missing or cracked FAW J6P Side Cladding panel not only looks unprofessional but also exposes the cab’s seams to corrosion and increases wind noise.

This group of components is integrated into the FAW J6P Side Cladding and is essential for operator safety, providing stable grab handles for cab entry and exit.

1. Component: ‘Left/Right front upper/lower armrest welding assy’ (5402115-B27, 5402120-B27) – Qty 1 each

This (Comp 8, 9) is the primary front grab handle. The Safety Logic is paramount. As a “welding assy,” this is a heavy-duty, one-piece steel component (likely a tube) that is welded to a strong mounting plate. It is designed to support the full weight of a driver, who may be pulling themselves into the cab in muddy or icy conditions. This is a critical safety feature of the FAW J6P Side Cladding system.

2. Component: ‘Left/Right rear upper/lower armrest welding assy’ (5402135-A86, 5402140-A86) – Qty 1 each

This (Comp 14, 15) is the rear grab handle, typically mounted on the cab’s rear pillar. This provides a second, higher grip point, allowing the driver to maintain three points of contact while climbing in. The robust design of this FAW J6P Side Cladding component is identical in principle to the front armrest.

3. Component: ‘Left/Right front armrest decorative cover’ (5402723-B27, 5402724-B27) – Qty 1 each

This (Comp 12, 13) is the cover that conceals the mounting hardware of the front armrest. The Finishing Logic is that this cover snaps over the mounting plate to provide a clean, finished look and, more importantly, to protect the ‘Combination bolts’ (Comp 10, 11) from corrosion. It also prevents the driver’s hands or clothing from snagging on the bolt heads.

This final group includes the specialized hardware used to secure the FAW J6P Side Cladding components. The choice of fasteners is critical to prevent vibration-induced failures.

1. Component: ‘Combination bolt’ (CQ1420820, CQ1460840F6, CQ1460820) – Qty 4, 4, 10

This (Comp 10, 11, 16) is the high-strength hardware used to mount the armrest assemblies (Comp 8, 9, 14, 15) to the cab’s steel pillars. The Combination Bolt Logic, featuring a pre-attached captive washer, is essential. It distributes the clamping load and ensures the washer is never omitted. These bolts must withstand immense shear and pull-out forces, making them the most critical part of the armrest installation.

2. Component: ‘Side cladding pad block C’ (5402173-A86) – Qty 2

This (Comp 17) is a specialized pad or spacer. The Damping Logic is that this block, likely made of high-density rubber, is placed between a cladding panel and the cab frame. It serves two purposes: first, it provides a precise “stand-off” distance to ensure the panel aligns correctly, and second, it absorbs vibration, preventing the hard panel from rattling against the metal cab. This is a key component for a quiet, long-lasting FAW J6P Side Cladding installation.

3. Component: ‘Cross recessed pan head screw assy’ (Q2360620F6, Q2360616F6) – Qty 2, 2

This (Comp 3, 4, 7) is the hardware used for lighter-duty attachments, such as securing the decorative panels (Comp 5, 6) to the cab. The “F6” suffix often indicates a specific finish or thread-locking patch, again highlighting the focus on vibration resistance for every part of the FAW J6P Side Cladding.

The following table provides the complete, detailed breakdown of all 17 component types in the FAW J6P Side Cladding and armrest assembly for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This list is essential for any service of the FAW J6P Side Cladding.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 5402715-B27 | Left front pillar upper guard assy | 1 |

| 2 | 5402720-B27 | Right front pillar upper guard assy | 1 |

| 3 | Q2360620F6 | Cross recessed pan head screw assy | 2 |

| 4 | Q2360616F6 | Cross recessed pan head screw assy | 2 |

| 5 | 5302771-A01 | Left front pillar lower decorative panel | 1 |

| 6 | 5302772-A01 | Right front pillar lower decorative panel | 1 |

| 7 | Q2360620F6 | Cross recessed pan head screw assy | 4 |

| 8 | 5402115-B27 | Left front upper/lower armrest welding assy | 1 |

| 9 | 5402120-B27 | Right front upper/lower armrest welding assy | 1 |

| 10 | CQ1420820 | Combination bolt | 4 |

| 11 | CQ1460840F6 | Combination bolt | 4 |

| 12 | 5402723-B27 | Left front upper/lower armrest decorative cover | 1 |

| 13 | 5402724-B27 | Right front upper/lower armrest decorative cover | 1 |

| 14 | 5402135-A86 | Left rear upper/lower armrest welding assy | 1 |

| 15 | 5402140-A86 | Right rear upper/lower armrest welding assy | 1 |

| 16 | CQ1460820 | Combination bolt | 10 |

| 17 | 5402173-A86 | Side cladding pad block C | 2 |

The specifications for the FAW J6P Side Cladding are defined by its dual function as an aerodynamic/protective panel and a structural mount for safety armrests.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | FAW J6P Side Cladding & Armrest Assembly |

| Primary Logic | Cab-side protection and driver/passenger access |

| Cladding Components | ‘Pillar upper guard’ (5402715/720-B27), ‘Lower decorative panel’ (5302771/772-A01) |

| Armrest Components | ‘Front armrest welding assy’ (5402115/120-B27), ‘Rear armrest’ (5402135/140-A86) |

| Damping Component | ‘Side cladding pad block C’ (5402173-A86) |

| Hardware | Combination bolts (CQ1420820, CQ1460840F6, CQ1460820) | Setting the ‘toe-in’ or ‘toe-out’ of the front wheels.

| Total Component Types | 17 |

| Associated System | Cab Exterior / Safety Access. The FAW J6P Side Cladding is a key structural/safety item. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.