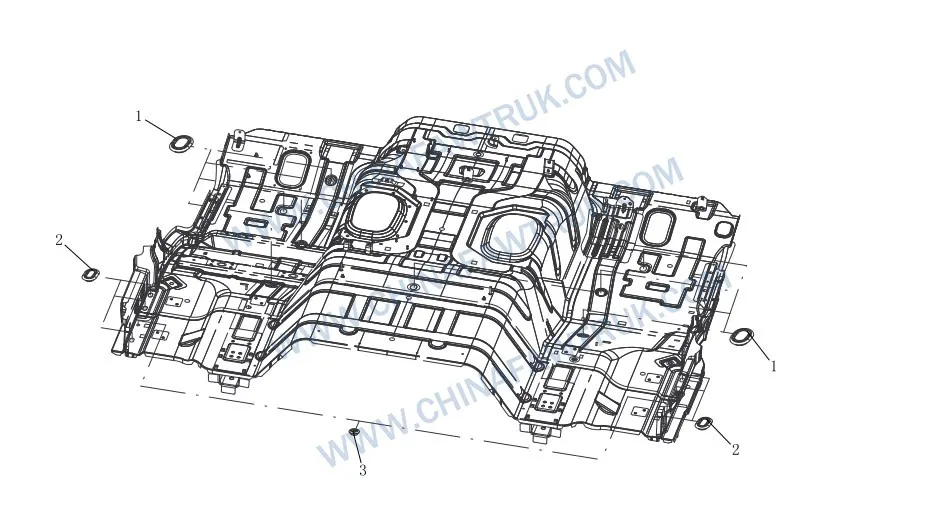

Conjunto de bloqueo de piso ruso FAW: 16 Sellos herméticos que protegen la cabina de la infiltración ártica

El Bloqueo de piso ruso FAW assembly is a critical sealing system for the CA3250P66K24L1TE5Z dump truck. que comprende 16 specialized components, this kit hermetically seals the manufacturing apertures in the steel floor pan. En el clima extremo de la Federación Rusa, these plugs prevent toxic exhaust fumes, freezing drafts, and corrosive road brine from infiltrating the driver’s workspace, ensuring a safe and comfortable cabin environment.

Bloqueo de piso ruso FAW

| No. |

Número de pieza |

Nombre de la pieza |

Cantidad |

| 1 | 5109613-A01 | Oval Plug D – Piso | 8 |

| 2 | 5109612-A01 | Oval Plug B – Piso | 6 |

| 3 | 5613163-A01 | Enchufar – Panel trasero | 2 |

FAW Russian Floor Blockage2

| No. |

Número de pieza |

Nombre de la pieza |

Cantidad |

| 1 | 5109616-A01 | Round Plug A – Piso | 12 |

| 2 | 5302821-A01 | Waterproof Membrane – Panel frontal | 9 |

| 3 | 5109619-A01 | Oval Plug C – Piso | 1 |

| 4 | 5302807-A01 | Oval Plug B – Panel frontal | 2 |

| 5 | 5109623-B45 | Floor Plug A | 1 |

Lógica de sellado: The Defense Against Infiltration

The primary role of the Bloqueo de piso ruso FAW is to complete the cabin’s watertight envelope. The kit includes Oval Plug D (Número de pieza. 5109613-A01) y Oval Plug B (Número de pieza. 5109612-A01), engineered for specific floor apertures. Unlike standard grommets, these plugs feature a complex dual-lip profile. This design bites into the sheet metal edge, creating a positive seal that resists displacement even during severe chassis articulation.

En el contexto ruso, a failed Bloqueo de piso ruso FAW component is a gateway for corrosion. Missing plugs allow salt-laden slush to inject directly under the floor mats. This brine acts as an electrolyte, corroding the floor pan from the inside out. The system ensures that only the zinc-coated underside is exposed, while the interior remains dry and protected.

Además, el Enchufar – Panel trasero (Número de pieza. 5613163-A01) seals the vertical rear wall. This area faces turbulent airflow that can suck water into the cabin. El Bloqueo de piso ruso FAW logic dictates that these rear plugs withstand higher wind loads. By securing these points, the system maintains the cabin’s positive pressure, essential for efficient HVAC operation in winter.

Ciencia de los materiales: Polymer Resilience in the Arctic

La durabilidad del Bloqueo de piso ruso FAW relies on high-grade Ethylene Propylene Diene Monomer (EPDM) synthetic rubber. Standard rubber becomes brittle at -30°C, but EPDM retains elasticity down to -50°C. This ensures the plugs remain secure in their mounting holes without shrinking or shattering under the intense vibration of a mining truck.

Además, el Bloqueo de piso ruso FAW materials resist chemical attack. The undercarriage is exposed to diesel spills and hydraulic leaks. An oil-resistant formulation prevents the plugs from swelling or dissolving. This chemical stability ensures that the seal remains tight throughout the vehicle’s operational lifespan, regardless of environmental contamination.

The rear plugs feature enhanced UV resistance to withstand weathering. While floor plugs are shielded, rear components face sunlight exposure. La ciencia material detrás del Bloqueo de piso ruso FAW ensures these parts do not chalk or crack. Esto evita “factory-fresh” seals from degrading, protecting the driver from the elements for years.

Acoustic Dampening and Fume Control

Beyond waterproofing, el Bloqueo de piso ruso FAW is vital for NVH management. Open floor holes act as acoustic leaks, transmitting transmission whine directly into the cab. The plugs act as mass dampers, blocking high-frequency noise. By sealing these 14 floor apertures, the system significantly lowers interior decibel levels, reducing driver fatigue during long shifts.

Lo más crítico, el Bloqueo de piso ruso FAW prevents fume intrusion. In stationary trucks with idling engines, exhaust gases accumulate under the chassis. A hermetic seal creates a gas-tight separation between the undercarriage and the driver’s breathing air. This protection prevents deadly carbon monoxide from seeping into the cabin, ensuring operator safety at loading zones.

La geometría del Oval Plug D includes a central diaphragm to absorb localized panel vibration. This prevents the plug itself from buzzing. El Bloqueo de piso ruso FAW ensures the acoustic environment meets professional standards, allowing drivers to hear radio communications clearly without interference from road noise.

Maintenance and Integrity Checks

Mantenimiento de la Bloqueo de piso ruso FAW involves visual checks during chassis greasing. A missing plug leaves a visible gap. Lifting floor mats can reveal damp spots indicating seal failure. If a plug is missing, it must be replaced immediately to prevent floor rot and maintain the integrity of the Bloqueo de piso ruso FAW sistema.

Installing these components requires checking the “snap-in” groove. The sheet metal edge must sit perfectly within this groove. If the plug is not seated correctly, vibration will dislodge it. For the rear panel plugs, inspecting for UV damage is essential. Proactive replacement ensures the Bloqueo de piso ruso FAW continúa desempeñando su función crítica.

Utilizar piezas originales FAW para el Bloqueo de piso ruso FAW es crucial. Universal grommets often lack the correct groove width for the J6P floor gauge. Genuine components are molded to exact tolerances, ensuring a watertight snap-fit. This restores the cabin’s protective envelope to factory specifications, safeguarding the vehicle’s interior.

Conclusión: The Unsung Heroes of Cabin Integrity

El Bloqueo de piso ruso FAW assembly is a testament to the importance of detail. Aunque simple en apariencia, el 16 items listed perform a vital function. They seal the cabin against the hostile environment, protecting the truck from corrosion and the driver from cold and fumes.

Para operadores de flotas, manteniendo el Bloqueo de piso ruso FAW is a high-reward strategy. Ensuring these plugs are intact preserves vehicle value and enhances driver satisfaction. In the extreme conditions of the Russian heavy transport sector, these small components make a massive difference in daily fleet viability.

Embalaje y Logística

piezas FAW, incluido el conjunto del bloque de cilindros, Se empaquetan con cuidado para garantizar una entrega segura.. Cada componente está asegurado con materiales protectores para evitar daños durante el transporte.. La red logística garantiza envíos puntuales en todo el mundo., apoyando operaciones de mantenimiento eficientes. A continuación se muestra una imagen que ilustra el embalaje estándar de las piezas de camiones FAW., mostrando la atención al detalle en el manejo y almacenamiento.

Este enfoque de embalaje minimiza el riesgo de corrosión o daños por impacto., asegurando que piezas como el conjunto de bloque de cilindros FAW lleguen en perfectas condiciones. Los clientes pueden confiar en la logística de FAW para obtener calidad y confiabilidad constantes.