FAW Russian Windscreen Wiper Assembly: 3 Critical Components Delivering Uncompromised Visibility in Blizzards

El FAW Russian Windscreen Wiper assembly is the primary vision safety system for the CA3250P66K24L1TE5Z dump truck. In the extreme latitudes of the Russian Federation, where visibility can be reduced to zero by driving snow and freezing fog, the reliability of this system is paramount. Unlike standard wipers, el FAW Russian Windscreen Wiper is engineered with a high-torque motor and reinforced linkage capable of pushing heavy loads of wet snow without stalling. This assembly ensures that the driver maintains a clear field of view, which is the single most important factor for accident prevention in mining operations.

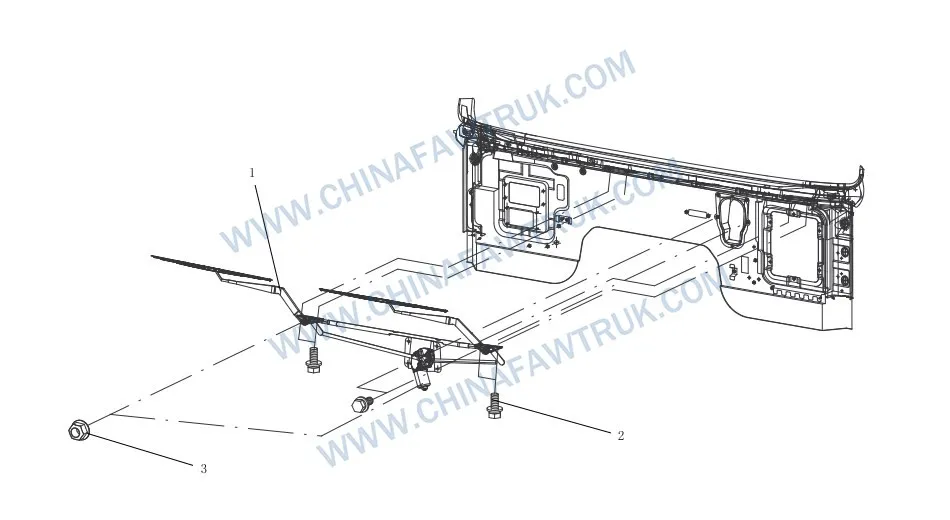

FAW Russian Windscreen Wiper

| No. |

Número de pieza |

Nombre de la pieza |

Cantidad |

| 1 | 5205010-A01 | Conjunto de limpiaparabrisas | 1 |

| 5205010AA01 | Conjunto de limpiaparabrisas | 1 |

| 2 | CQ1460825F6 | Perno combinado | 6 |

| 3 | CQ32608 | Hexagon Head Flange Lock Nut | 2 |

Motor Torque and Linkage Geometry

El núcleo de la FAW Russian Windscreen Wiper system is the Conjunto de limpiaparabrisas (Número de pieza. 5205010-A01 or 5205010AA01). This unit is not merely a motor; it is a fully integrated kinematic system comprising the DC electric motor, the reduction gearbox, and the reciprocating linkage bars. In the heavy-duty application of the CA3250 dump truck, the motor is sized to generate significant torque. This is critical for the FAW Russian Windscreen Wiper because the resistance on the glass can vary wildly. Wet snow, sticky mud, or a layer of semi-frozen slush can increase the load on the wiper arms by a factor of ten compared to simple rain. A standard automotive wiper motor would overheat and burn out under these conditions, leaving the driver blind.

The linkage geometry within the FAW Russian Windscreen Wiper assembly is engineered to maximize the sweep area while maintaining a high contact pressure between the blade and the glass. The pivots are sealed against moisture and grit ingress, which is essential for the dusty environment of a mine site. El “A01” specification often denotes a cold-weather grease packing in the gear housing, ensuring that the internal mechanism of the FAW Russian Windscreen Wiper does not stiffen or seize when the temperature drops to -40°C. This attention to internal lubrication ensures smooth, chatter-free operation during the initial cold start.

Además, el Conjunto de limpiaparabrisas includes an internal thermal breaker. This safety device protects the motor windings if the blades are physically frozen to the windshield—a common occurrence in Russia. Instead of burning out the motor coils, el FAW Russian Windscreen Wiper logic cuts power until the obstruction is cleared or the motor cools down. This self-protection feature significantly extends the service life of the component, reducing the need for costly replacements in the field.

Heavy-Duty Fastening Strategy

The mounting of the FAW Russian Windscreen Wiper mechanism to the firewall is achieved through a redundant fastening system involving 6 units of the Perno combinado (Número de pieza. CQ1460825F6). These are not standard screws; they are M8 high-tensile bolts equipped with integrated captive washers. The use of six attachment points distributes the reactive torque of the wiper motor across a broad section of the sheet metal firewall. During high-speed wiping or when pushing heavy snow, the motor generates a powerful twisting force. Without secure multi-point fastening, el FAW Russian Windscreen Wiper assembly could flex, leading to metal fatigue and cracking of the mounting bulkhead.

El “F6” designation on the Perno combinado indicates a specialized corrosion-resistant coating, typically a zinc-aluminum flake finish. In the salt-spray environment of Russian winter roads, standard fasteners would rust rapidly, potentially seizing in the welded nuts. The corrosion resistance of the FAW Russian Windscreen Wiper hardware ensures that the assembly remains serviceable. Mechanics can remove the unit for repair or replacement even after years of exposure to brine, without the risk of snapping bolt heads.

Además, the captive washers on the bolts provide a locking function and protect the paint around the mounting holes. By preventing the bolt head from rotating directly against the bodywork, el FAW Russian Windscreen Wiper installation process avoids damaging the anti-corrosion primer of the cab. This detail is crucial for maintaining the structural integrity of the front panel, preventing rust from starting at the wiper mounting points.

Vibration Control and Security

To secure the wiper arm pivots or the main motor shaft, the system utilizes the Hexagon Head Flange Lock Nut (Número de pieza. CQ32608). These nuts feature an integrated flange that acts as a washer, spreading the clamping load over a larger area. El “cerrar” feature, likely a distorted thread or nylon insert, is essential for the FAW Russian Windscreen Wiper solicitud. Mining trucks are subjected to constant low-frequency vibration from the diesel engine and high-frequency shocks from the road surface. This vibrational energy can loosen standard nuts, causing the wiper linkage to become sloppy or disconnect entirely.

El FAW Russian Windscreen Wiper relies on the precise torque retention of these lock nuts to maintain the alignment of the wiper arms. If the linkage nuts loosen, the sweep angle of the blades can drift, causing the wipers to slap against the A-pillar or the bottom of the windscreen cowl. This not only creates annoying noise but damages the wiper blades and the paintwork. The self-locking nature of the Hexagon Head Flange Lock Nut ensures that the geometry set at the factory remains constant throughout the vehicle’s operation.

Además, the flange design provides a better seal against moisture intrusion at the pivot points. By covering the hole clearance completely, the nut prevents water from wicking down the threads into the mechanism below. This contributes to the overall weather-proofing of the FAW Russian Windscreen Wiper sistema, protecting the valuable interior components behind the dashboard from water damage.

Operational Maintenance

Manteniendo el FAW Russian Windscreen Wiper is critical for safety. Drivers should inspect the condition of the blades daily, especially in winter. Using the wipers to clear ice without defrosting first is the leading cause of damage to the Conjunto de limpiaparabrisas linkage and motor. El FAW Russian Windscreen Wiper es robusto, but mechanical empathy is required to prevent overloading the system. Fleet operators should also check the tightness of the 6 mounting bolts during scheduled services to ensure the motor remains rigidly attached.

If the wipers become slow or jerky, it often indicates a failing motor or seized linkage pivots. En el FAW Russian Windscreen Wiper unidad, the motor and linkage are typically replaced as a complete assembly (Número de pieza. 5205010-A01), simplifying the repair process. Attempting to rebuild the linkage in the field is time-consuming and often ineffective due to wear in the pivot bushings.

Using genuine FAW parts for the FAW Russian Windscreen Wiper es esencial. Universal motors often lack the correct torque curve and park-position logic required by the J6P’s body controller. Installing an under-powered aftermarket motor can result in blade stall during heavy snow, creating a dangerous situation. The genuine assembly is tested to perform at the specific voltage and load conditions of the FAW electrical system.

Conclusión: Clear Vision, Safe Operation

El FAW Russian Windscreen Wiper assembly is a vital safety system comprising the motor unit, enlace, and specialized fastening hardware. While it consists of only 3 main component types, its role in ensuring driver visibility is irreplaceable. The robust design handles the extreme loads of Arctic weather, providing reliable clearing power when it is needed most.

Para los gerentes de flota, el FAW Russian Windscreen Wiper requires respect and regular maintenance. Ensuring that the motor is secure, the nuts are tight, and the blades are fresh guarantees that the truck can operate safely in all weather conditions. By prioritizing the health of this system, operators protect their drivers and their assets from the risks of low-visibility accidents.

Embalaje y Logística

piezas FAW, incluido el conjunto del bloque de cilindros, Se empaquetan con cuidado para garantizar una entrega segura.. Cada componente está asegurado con materiales protectores para evitar daños durante el transporte.. La red logística garantiza envíos puntuales en todo el mundo., apoyando operaciones de mantenimiento eficientes. A continuación se muestra una imagen que ilustra el embalaje estándar de las piezas de camiones FAW., mostrando la atención al detalle en el manejo y almacenamiento.

Este enfoque de embalaje minimiza el riesgo de corrosión o daños por impacto., asegurando que piezas como el conjunto de bloque de cilindros FAW lleguen en perfectas condiciones. Los clientes pueden confiar en la logística de FAW para obtener calidad y confiabilidad constantes.