Tanque de expansión ruso FAW: Masterización 31 Componentes críticos para un control de presión impecable

El Tanque de expansión ruso FAW El conjunto lógico es el corazón regulador de presión del camión volquete CA3250P66K24L1TE5Z.. Situado en el punto más alto del circuito de enfriamiento., Este complejo sistema gestiona la expansión térmica del refrigerante., elimina las bolsas de aire destructivas, y mantiene la elevación del punto de ebullición necesaria para operaciones de servicio pesado. En el Ártico ruso, donde las diferencias de temperatura pueden romper los depósitos estándar, este conjunto garantiza la estabilidad hidráulica.

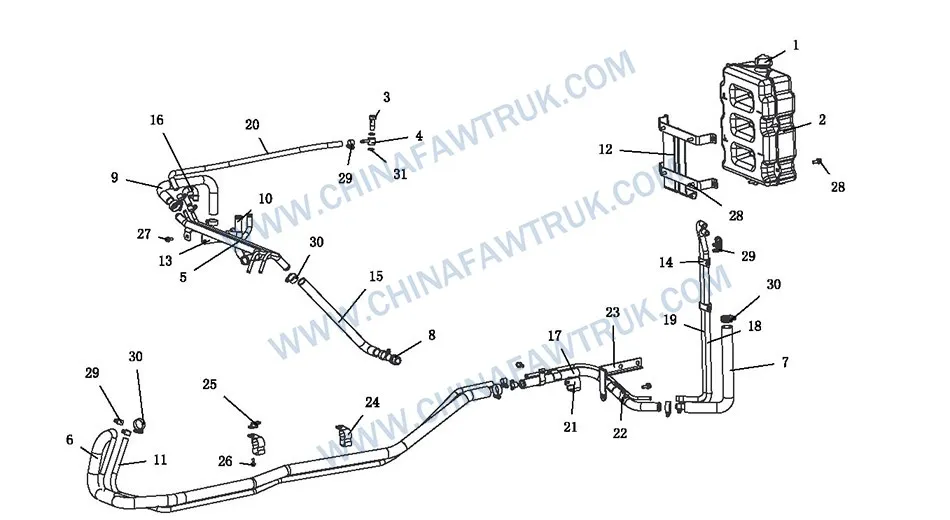

Conjunto lógico del tanque de expansión ruso FAW

Dinámica del yacimiento: El conjunto del tanque de expansión

La pieza central del sistema es la Conjunto del tanque de expansión (Número de pieza. 1311020-76A). En el contexto de la Tanque de expansión ruso FAW lógica, este componente es mucho más que una simple botella de plástico. Es un recipiente a presión de doble cámara fabricado con acero de alta calidad., polipropileno reforzado con vidrio (PÁGINAS) o compuesto de poliamida. Esta selección de materiales es fundamental para el mercado ruso.. Los plásticos estándar se vuelven quebradizos a -40°C y pueden romperse bajo la carga vibratoria de un motor diésel.. La especificación FAW garantiza que el tanque conserve la ductilidad en el congelador mientras resiste la deformación a temperaturas de funcionamiento superiores a 100 °C..

La translucidez del Tanque de expansión ruso FAW es otra característica diseñada. Permite a los operadores verificar visualmente los niveles y la claridad del refrigerante sin abrir el sistema., una característica de seguridad crucial cuando el sistema está presurizado y muy caliente. Los deflectores internos dentro del tanque calman la turbulencia del refrigerante que regresa. Este “calmando” El efecto permite que las burbujas de aire arrastradas se separen del líquido y suban al espacio de aire en la parte superior del tanque.. Si esta separación no se produce, El refrigerante aireado regresa a la bomba de agua., conduciendo a la cavitación, erosión del impulsor, y sobrecalentamiento localizado en las culatas.

Limitar este sistema es el Conjunto de tapa de presión (Número de pieza. 1304010-50A). Esta es la válvula de seguridad principal del Tanque de expansión ruso FAW. Está calibrado para mantener una presión específica del sistema. (típicamente alrededor 1.0 a 1.2 bar). Al aumentar la presión, la tapa eleva el punto de ebullición de la mezcla refrigerante, Evitar el desbordamiento durante las subidas de cargas elevadas fuera de los pozos mineros.. En caso de sobrepresión, la tapa ventila el exceso de gas; a medida que el motor se enfría y se contrae, Permite que el aire atmosférico vuelva a entrar para evitar que las mangueras colapsen bajo el vacío.. La precisión de este mecanismo accionado por resorte es vital para mantener el equilibrio térmico de todo el tren motriz..

Lógica de desaireación: Eliminación de bolsas de vapor

Una característica única del Tanque de expansión ruso FAW montaje es su amplia red de líneas de desgasificación. Esto incluye el Conjunto de tubería de desgasificación del motor (Número de pieza. 1311025-138), Manguera de goma desgasificadora variantes (Números de pieza. 1311036-14B, 1311068-61B), y el Manguera de goma desgasificadora trasera del radiador (Número de pieza. 1311069-76A). Estos componentes forman un sistema circulatorio diseñado para eliminar las bolsas de aire de los puntos altos del motor y el radiador.. En el Tanque de expansión ruso FAW lógica, La desaireación continua no es negociable..

Las bolsas de aire son aislantes térmicos.. Si queda atrapada una bolsa de vapor o aire en los conductos de enfriamiento de la culata del cilindro, evita que el refrigerante toque el metal. Esto conduce a una rápida, localizado “puntos calientes” que pueden agrietar la fundición de la culata o deformar las válvulas, incluso si el indicador de temperatura indica normal. El Tanque de expansión ruso FAW El sistema purga continuamente un pequeño volumen de refrigerante desde estos puntos altos de regreso al tanque., llevando consigo el aire atrapado.

La conexión al motor se facilita mediante el Perno hueco desgasificador (Número de pieza. 1311024-249). Este perno banjo especializado presenta un orificio calibrado que restringe el flujo.. Esto asegura que mientras el aire pueda escapar, El volumen principal de presión del refrigerante no se pierde en la línea de purga.. La integración de tuberías metálicas como la Conjunto de tubería de acero de retorno (Número de pieza. 1311035-61B) en zonas de alto calor garantiza que las líneas de desgasificación no se fundan ni se degraden, manteniendo la integridad de la Tanque de expansión ruso FAW circuito de desaireación a lo largo de la vida útil del vehículo.

Dinámica de circulación: Mangueras y tuberías de retorno

La lógica del transporte de fluidos implica una combinación de caucho flexible y acero rígido.. Componentes como el Manguera de goma de retorno (Número de pieza. 1311033-14B) y el Conjunto de tubería de acero de retorno trasero (Número de pieza. 1311065-14B) gestionar el flujo de refrigerante de regreso a la entrada de la bomba de agua. En el Tanque de expansión ruso FAW diseño, Se utilizan tubos de acero para recorridos largos a lo largo del bloque del motor para garantizar rigidez y protección contra la abrasión.. Estas tuberías están tratadas químicamente para resistir la corrosión del duro entorno externo de las carreteras rusas saladas..

Las secciones flexibles, como el Manguera de goma de retorno frontal (Número de pieza. 1311034-61B), Están fabricados con caucho EPDM de grado ártico.. Este material permanece flexible a -40°C., Evitar que las conexiones de las mangueras tengan fugas debido a la contracción en frío.. Una manguera de goma estándar se endurecería en estas condiciones., perdiendo su presión de sellado contra las púas de la tubería de metal. El Tanque de expansión ruso FAW Las mangueras están reforzadas con un trenzado interno de fibra para resistir el estallido bajo los aumentos repentinos de presión causados por el funcionamiento de la bomba de agua a altas RPM..

Conectar estos segmentos requiere hardware de precisión como el Conector de tubo de retorno (Número de pieza. 1311034-50A) y el Conjunto de tubería de conexión (Número de pieza. 1311025-61B). Estos conectores garantizan transiciones suaves entre diámetros de manguera, minimizando la turbulencia. La turbulencia en la línea de retorno puede inducir aireación., frustrando el propósito de la Tanque de expansión ruso FAW. El sistema está diseñado para proporcionar flujo laminar., asegurar que la bomba de agua reciba una columna sólida de refrigerante líquido, maximizando su eficiencia y longevidad.

Integridad del montaje: Soportes y Abrazaderas Tipo B

Asegurar esta compleja red de 31 Los componentes requieren una estrategia de montaje sólida.. El Conjunto de soporte del tanque de expansión (Número de pieza. 1311040-61C) Ancla el depósito al punto más alto del cortafuegos o chasis.. Este soporte debe ser lo suficientemente rígido para soportar el peso del tanque lleno de refrigerante. (varios kilogramos) bajo cargas de choque 3G comunes en la minería. Simultáneamente, Debe amortiguar las vibraciones para evitar grietas por tensión en el cuerpo del tanque.. El Tanque de expansión ruso FAW La lógica de montaje generalmente emplea aisladores de goma en los puntos de interfaz..

La red de tuberías está asegurada por el Conjunto de abrazadera de tubería doble (Número de pieza. 1311060-61B) y Clip de tubo único (Número de pieza. 1311071A377). Estos organizadores evitan que las mangueras rocen entre sí o con el bloque del motor caliente.. En un ambiente de alta vibración, una manguera suelta puede desgastarse en cuestión de días. El Tanque de expansión ruso FAW El ensamblaje garantiza que cada milímetro de tubería esté ubicado positivamente y protegido contra daños físicos..

críticamente, las conexiones de las mangueras están selladas con Abrazadera de manguera con tornillo sin fin tipo B (Número de pieza. CQ67622B y CQ67640B). El “Tipo B” La designación indica un diseño con borde enrollado.. A diferencia de las abrazaderas de banda plana baratas que cortan la goma de la manguera cuando se aprietan, Las abrazaderas con borde enrollado protegen la superficie de EPDM.. Esto es vital para el Tanque de expansión ruso FAW mangueras, que puede ser necesario reapretar en el campo. El uso de la abrazadera correcta garantiza que la manguera siga siendo reutilizable y sin fugas., Preservar la integridad del sistema de refrigeración en los entornos más hostiles..

Desglose de componentes: 97. Tanque de expansión, Conjunto de lógica de tubería

| No. |

Número de pieza |

Nombre de la pieza |

Cantidad |

| 1 | 1304010-50A | Conjunto de tapa de presión | 1 |

| 2 | 1311020-76A | Conjunto del tanque de expansión | 1 |

| 3 | 1311024-249 | Perno hueco desgasificador | 1 |

| 4 | 1311025-138 | Conjunto de tubería de desgasificación del motor | 1 |

| 5 | 1311025-61B | Conjunto de tubería de conexión | 1 |

| 6 | 1311033-14B | Manguera de goma de retorno | 1 |

| 7 | 1311033-61B | Manguera de goma de retorno trasero | 1 |

| 8 | 1311034-50A | Conector de tubo de retorno | 1 |

| 9 | 1311034-61B | Manguera de goma de retorno frontal | 1 |

| 10 | 1311035-61B | Conjunto de tubería de acero de retorno (Patrón) | 1 |

| 11 | 1311036-14B | Manguera de goma desgasificadora | 2 |

| 12 | 1311040-61C | Conjunto de soporte del tanque de expansión | 1 |

| 13 | 1311045-61B | Conjunto de soporte | 1 |

| 14 | 1311060-61B | Conjunto de abrazadera de tubería doble | 2 |

| 15 | 1311062-14B | Manguera de goma de retorno | 1 |

| 16 | 1311063-61B | Manguera de goma para desgasificación del radiador | 1 |

| 17 | 1311065-14B | Conjunto de tubería de acero de retorno trasero | 1 |

| 18 | 1311068-61B | Manguera de goma desgasificadora | 1 |

| 19 | 1311069-61B | Manguera de goma desgasificadora trasera | 1 |

| 20 | 1311069-76A | Manguera de goma desgasificadora trasera del radiador | 1 |

| 21 | 1311070-14B | Conjunto de soporte | 1 |

| 22 | 1311071A377 | Clip de tubo único | 1 |

| 23 | 1311075-14B | Conjunto de soporte | 1 |

| 24 | 1311077-61B | Clip de manguera | 2 |

| 25 | 1311080-91W. | Conjunto de soporte de manguera de goma de desgasificación | 1 |

| 26 | CQ1460620 | Perno combinado | 1 |

| 27 | Q1840816 | Perno de brida hexagonal Vástago grueso | 2 |

| 28 | CQ1460825 | Perno combinado | 11 |

| 29 | CQ67622B | Abrazadera de manguera con tornillo sin fin tipo B | 12 |

| 30 | CQ67640B | Abrazadera de manguera con tornillo sin fin tipo B | 8 |

| 31 | CQ2314T5 | Anillo de sellado | 2 |

Conclusión: El guardián de la presión

El Tanque de expansión ruso FAW El conjunto sirve como guardián presurizado de la salud térmica del motor.. Aunque a menudo se pasa por alto, es 31 Los componentes trabajan en conjunto para estabilizar la presión., eliminar el aire, y encaminar el refrigerante de manera eficiente. Desde el depósito de plástico reforzado hasta las válvulas desgasificadoras especializadas, Cada pieza está diseñada para soportar las demandas extremas del Ártico ruso..

Para los gerentes de flota, el Tanque de expansión ruso FAW es un punto de control crítico. Un tanque agrietado, una tapa de presión defectuosa, o una línea de desgasificación obstruida puede provocar un rápido sobrecalentamiento y falla del motor. Al garantizar que este conjunto se mantenga con materiales genuinos, componentes resistentes al frío, Los operadores protegen su inversión y garantizan que sus camiones permanezcan operativos en las condiciones más duras del planeta..

Embalaje y Logística

piezas FAW, incluido el conjunto del bloque de cilindros, Se empaquetan con cuidado para garantizar una entrega segura.. Cada componente está asegurado con materiales protectores para evitar daños durante el transporte.. La red logística garantiza envíos puntuales en todo el mundo., apoyando operaciones de mantenimiento eficientes. A continuación se muestra una imagen que ilustra el embalaje estándar de las piezas de camiones FAW., mostrando la atención al detalle en el manejo y almacenamiento.

Este enfoque de embalaje minimiza el riesgo de corrosión o daños por impacto., asegurando que piezas como el conjunto de bloque de cilindros FAW lleguen en perfectas condiciones. Los clientes pueden confiar en la logística de FAW para obtener calidad y confiabilidad constantes.