Tanque de Expansão Russo FAW: Masterização 31 Componentes críticos para controle de pressão impecável

O Tanque de Expansão Russo FAW logic assembly is the pressure-regulating heart of the CA3250P66K24L1TE5Z dump truck. Situated at the highest point of the cooling loop, this complex system manages coolant thermal expansion, eliminates destructive air pockets, and maintains the boiling point elevation necessary for heavy-duty operation. No Ártico Russo, where temperature differentials can crack standard reservoirs, this assembly ensures hydraulic stability.

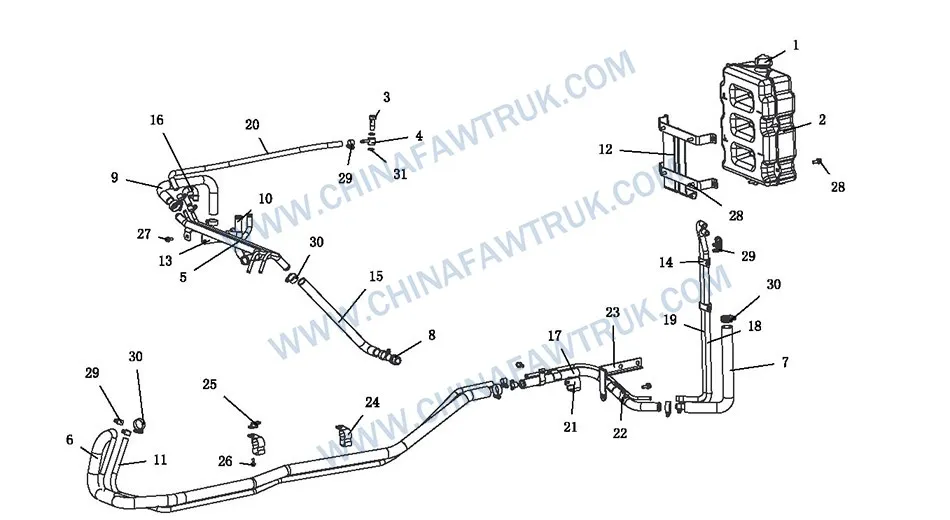

FAW Russian Expansion Tank Logic Assembly

Reservoir Dynamics: The Expansion Tank Assembly

The centerpiece of the system is the Conjunto do tanque de expansão (Parte não. 1311020-76A). No contexto do Tanque de Expansão Russo FAW lógica, this component is far more than a simple plastic bottle. It is a dual-chambered pressure vessel manufactured from a high-grade, glass-reinforced polypropylene (PP) or polyamide composite. This material selection is critical for the Russian market. Standard plastics become brittle at -40°C and can shatter under the vibrational load of a diesel engine. The FAW specification ensures that the tank retains ductility in the deep freeze while resisting deformation at operating temperatures exceeding 100°C.

The translucency of the Tanque de Expansão Russo FAW is another engineered feature. It allows operators to visually verify coolant levels and clarity without opening the system, a crucial safety feature when the system is pressurized and scalding hot. Internal baffles within the tank calm the turbulence of the returning coolant. Esse “stilling” effect allows entrained air bubbles to separate from the liquid and rise to the air space at the top of the tank. If this separation does not occur, aerated coolant is drawn back into the water pump, leading to cavitation, impeller erosion, and localized overheating in the cylinder heads.

Capping this system is the Pressure Cap Assembly (Parte não. 1304010-50A). This is the primary safety valve of the Tanque de Expansão Russo FAW. It is calibrated to maintain a specific system pressure (typically around 1.0 para 1.2 bar). By raising the pressure, the cap raises the boiling point of the coolant mixture, preventing boil-over during high-load climbs out of mining pits. In the event of over-pressure, the cap vents excess gas; as the engine cools and contracts, it allows atmospheric air back in to prevent the hoses from collapsing under vacuum. The precision of this spring-loaded mechanism is vital for maintaining the thermal equilibrium of the entire powertrain.

De-Aeration Logic: Eliminating Steam Pockets

Uma característica única do Tanque de Expansão Russo FAW assembly is its extensive network of degassing lines. This includes the Engine Degassing Pipe Assembly (Parte não. 1311025-138), Degassing Rubber Hose variantes (Números de peças. 1311036-14B, 1311068-61B), e o Radiator Rear Degassing Rubber Hose (Parte não. 1311069-76A). These components form a circulatory system designed to scavenge air pockets from high points in the engine and radiator. No Tanque de Expansão Russo FAW lógica, continuous de-aeration is non-negotiable.

Air pockets are thermal insulators. If a pocket of steam or air becomes trapped in the cylinder head cooling passages, it prevents the coolant from touching the metal. This leads to rapid, localized “pontos quentes” that can crack the cylinder head casting or warp the valves, even if the temperature gauge reads normal. O Tanque de Expansão Russo FAW system continuously bleeds a small volume of coolant from these high points back to the tank, carrying the trapped air with it.

The connection to the engine is facilitated by the Degassing Hollow Bolt (Parte não. 1311024-249). This specialized banjo bolt features a calibrated orifice that restricts flow. This ensures that while air can escape, the main volume of coolant pressure is not lost to the bleed line. The integration of metal pipes like the Return Steel Pipe Assembly (Parte não. 1311035-61B) in high-heat zones ensures that the degassing lines do not melt or degrade, mantendo a integridade do Tanque de Expansão Russo FAW de-aeration loop over the vehicle’s lifespan.

Dinâmica de Circulação: Return Hoses and Pipes

The fluid transport logic involves a combination of flexible rubber and rigid steel. Componentes como o Return Rubber Hose (Parte não. 1311033-14B) e o Rear Return Steel Pipe Assembly (Parte não. 1311065-14B) manage the flow of coolant back to the water pump inlet. No Tanque de Expansão Russo FAW projeto, steel pipes are used for long runs across the engine block to ensure rigidity and protection against abrasion. These pipes are chemically treated to resist corrosion from the harsh external environment of salted Russian roads.

The flexible sections, como o Front Return Rubber Hose (Parte não. 1311034-61B), are manufactured from Arctic-grade EPDM rubber. This material remains pliable at -40°C, preventing the hose connections from leaking due to cold-shrinkage. A standard rubber hose would harden in these conditions, losing its sealing pressure against the metal pipe barbs. O Tanque de Expansão Russo FAW hoses are reinforced with internal fiber braiding to resist bursting under the pressure surges caused by high-RPM water pump operation.

Connecting these segments requires precision hardware like the Return Pipe Connector (Parte não. 1311034-50A) e o Conjunto do tubo de conexão (Parte não. 1311025-61B). These connectors ensure smooth transitions between hose diameters, minimizing turbulence. Turbulence in the return line can induce aeration, defeating the purpose of the Tanque de Expansão Russo FAW. The system is designed to provide laminar flow, ensuring that the water pump receives a solid column of liquid coolant, maximizing its efficiency and longevity.

Integridade de montagem: Brackets and Type B Clamps

Securing this complex web of 31 components requires a robust mounting strategy. O Expansion Tank Bracket Assembly (Parte não. 1311040-61C) anchors the reservoir to the highest point on the firewall or chassis. This bracket must be rigid enough to support the weight of the coolant-filled tank (several kilograms) under 3G shock loads common in mining. Simultaneamente, it must dampen vibration to prevent stress cracks in the tank body. O Tanque de Expansão Russo FAW mounting logic typically employs rubber isolators at the interface points.

The tubing network is secured by the Conjunto de braçadeira de tubo duplo (Parte não. 1311060-61B) e Clipe de tubo único (Parte não. 1311071A377). These organizers prevent the hoses from chafing against each other or the hot engine block. In a high-vibration environment, a loose hose can wear through in a matter of days. O Tanque de Expansão Russo FAW assembly ensures that every millimeter of piping is positively located and protected from physical damage.

Criticamente, the hose connections are sealed with Braçadeira de mangueira sem-fim tipo B (Parte não. CQ67622B and CQ67640B). O “Type B” designation indicates a rolled-edge design. Unlike cheap flat-band clamps that slice into the hose rubber when tightened, rolled-edge clamps protect the EPDM surface. Isto é vital para o Tanque de Expansão Russo FAW mangueiras, which may need to be retightened in the field. Using the correct clamp ensures the hose remains reusable and leak-free, preserving the integrity of the cooling system in the most hostile environments.

Divisão de Componentes: 97. Tanque de expansão, Pipeline Logic Assembly

| Não. |

Número da peça |

Nome da peça |

Quantidade |

| 1 | 1304010-50A | Pressure Cap Assembly | 1 |

| 2 | 1311020-76A | Conjunto do tanque de expansão | 1 |

| 3 | 1311024-249 | Degassing Hollow Bolt | 1 |

| 4 | 1311025-138 | Engine Degassing Pipe Assembly | 1 |

| 5 | 1311025-61B | Conjunto do tubo de conexão | 1 |

| 6 | 1311033-14B | Return Rubber Hose | 1 |

| 7 | 1311033-61B | Rear Return Rubber Hose | 1 |

| 8 | 1311034-50A | Return Pipe Connector | 1 |

| 9 | 1311034-61B | Front Return Rubber Hose | 1 |

| 10 | 1311035-61B | Return Steel Pipe Assembly (Padrão) | 1 |

| 11 | 1311036-14B | Degassing Rubber Hose | 2 |

| 12 | 1311040-61C | Expansion Tank Bracket Assembly | 1 |

| 13 | 1311045-61B | Montagem de suporte | 1 |

| 14 | 1311060-61B | Conjunto de braçadeira de tubo duplo | 2 |

| 15 | 1311062-14B | Return Rubber Hose | 1 |

| 16 | 1311063-61B | Radiator Degassing Rubber Hose | 1 |

| 17 | 1311065-14B | Rear Return Steel Pipe Assembly | 1 |

| 18 | 1311068-61B | Degassing Rubber Hose | 1 |

| 19 | 1311069-61B | Rear Degassing Rubber Hose | 1 |

| 20 | 1311069-76A | Radiator Rear Degassing Rubber Hose | 1 |

| 21 | 1311070-14B | Montagem de suporte | 1 |

| 22 | 1311071A377 | Clipe de tubo único | 1 |

| 23 | 1311075-14B | Montagem de suporte | 1 |

| 24 | 1311077-61B | Hose Clip | 2 |

| 25 | 1311080-91C | Degassing Rubber Hose Bracket Assembly | 1 |

| 26 | CQ1460620 | Parafuso de combinação | 1 |

| 27 | Q1840816 | Haste grossa do parafuso de flange hexagonal | 2 |

| 28 | CQ1460825 | Parafuso de combinação | 11 |

| 29 | CQ67622B | Braçadeira de mangueira sem-fim tipo B | 12 |

| 30 | CQ67640B | Braçadeira de mangueira sem-fim tipo B | 8 |

| 31 | CQ72314T5 | Anel de vedação | 2 |

Conclusão: The Guardian of Pressure

O Tanque de Expansão Russo FAW assembly serves as the pressurized guardian of the engine’s thermal health. While often overlooked, isso é 31 components work in concert to stabilize pressure, eliminate air, and route coolant efficiently. From the reinforced plastic reservoir to the specialized degassing valves, every part is engineered to withstand the extreme demands of the Russian Arctic.

Para gerentes de frota, o Tanque de Expansão Russo FAW is a critical checkpoint. A cracked tank, a faulty pressure cap, or a clogged degassing line can lead to rapid overheating and engine failure. By ensuring that this assembly is maintained with genuine, cold-resistant components, operators protect their investment and ensure their trucks remain operational in the harshest conditions on the planet.

Embalagem e Logística

Peças FAW, incluindo o conjunto do bloco de cilindros, são embalados com cuidado para garantir uma entrega segura. Cada componente é protegido por materiais de proteção para evitar danos durante o transporte. A rede logística garante envios pontuais em todo o mundo, apoiando operações de manutenção eficientes. Abaixo está uma imagem ilustrando a embalagem padrão para peças de caminhão FAW, mostrando a atenção aos detalhes no manuseio e armazenamento.

Esta abordagem de embalagem minimiza o risco de corrosão ou danos por impacto, garantindo que peças como o conjunto do bloco de cilindros FAW cheguem em perfeitas condições. Os clientes podem confiar na logística da FAW para obter qualidade e confiabilidade consistentes.