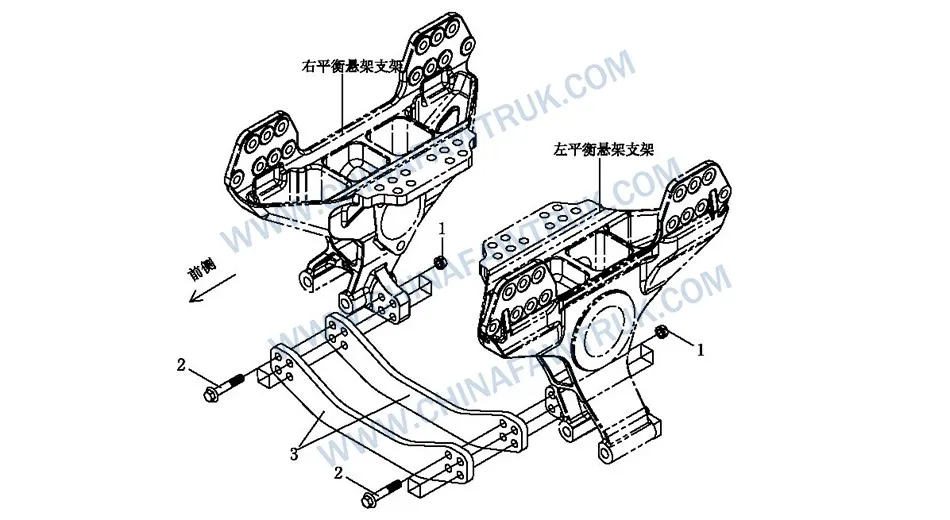

Balance Suspension Bracket Connection Plate: Engineering 3 Strategic Components for Ultimate Torsional Rigidity

The Balance Suspension Bracket Connection Plate logic assembly is a critical structural element in the heavy-duty rear bogie of the CA3250P66K24L1TE5Z dump truck. Its primary function is to rigidly link the balance suspension bracket to the chassis frame rail, ensuring that the lateral and torsional forces generated by the tandem axles are distributed without compromise. Engineered with “55R” cold-specification steel, the Balance Suspension Bracket Connection Plate is designed to prevent frame fatigue and maintains the axle’s geometric alignment across the immense thermal range of the Siberian mining environment. This guide details the high-shear fastening system and the structural purpose of this vital chassis reinforcement.

Balance Suspension Bracket Connection Plate

Plate Metallurgy and Structural Load Path

The primary component is the **Connection Plate** (Part No. 2919172-55R). This heavy-gauge steel plate is strategically placed to bridge high-stress sections of the balance suspension bracket and the chassis frame. Its “55R” specification denotes a high-yield steel alloy selected for its superior fracture toughness at low temperatures. Standard structural steel, when exposed to -50°C, can become brittle, leading to catastrophic fatigue cracks originating at the bolt holes. The **Balance Suspension Bracket Connection Plate** retains its elasticity, allowing controlled micro-flexing without permanent deformation, which is essential for surviving the continuous shock loads from frozen ruts.

The geometry of the **Connection Plate** is meticulously designed to distribute localized forces over a wider area of the frame web. This function prevents tearing or shearing of the frame material around the suspension mounting points. The plate acts as a gusset, reinforcing the junction between the vertical face of the balance bracket and the horizontal or vertical plane of the chassis rail. This reinforcement is critical for the stability of the entire rear bogie system, ensuring that the axles remain square to the **Balance Suspension Bracket Connection Plate** centerline under maximum payload and off-road articulation.

Surface preparation and coating are vital for the longevity of the **Connection Plate**. Located low on the chassis, it is constantly exposed to road salt, mud, and water. The **Balance Suspension Bracket Connection Plate** undergoes a rigorous coating process to prevent rust, which could otherwise compromise the material’s thickness and lead to failure. Corrosion must be avoided, as it can cause “rust jacking” between the plate and the frame rail, forcing the components apart and stressing the mounting bolts until they fail.

The structural role of the **Balance Suspension Bracket Connection Plate** is to resist the rotational torque imparted by the suspension system onto the frame during braking and acceleration. By increasing the effective cross-sectional thickness of the bolted joint, the plate multiplies the friction grip between the components. This added rigidity ensures that the axle maintains its location, which is a key factor in preventing “axle wind-up” and wheel hop during low-traction maneuvering in the Russian operational theater.

Advanced Fastening and Anti-Loosening Logic

The security of the **Balance Suspension Bracket Connection Plate** is guaranteed by high-tensile flange bolts and specialized locking nuts. Eight **Hexagon Head Flange Bolts** (Part No. Q18518100T) are used to create the clamping force. These bolts feature a high-strength rating (Grade 10.9 or higher) to withstand the immense static and dynamic loads. The flange head distributes the tension evenly across the plate surface, ensuring that the load path remains stable.

Mating with these bolts are eight **SPL Hex Small Flange Anti-loose Nuts** (Part No. T32718TF2). The SPL (Self-Prevailing Lock) technology is vital for the **Balance Suspension Bracket Connection Plate**. It uses a specialized thread deformation to create a mechanical lock that resists vibration-induced loosening. This all-metal locking mechanism is superior to nylon insert nuts in extreme cold environments, as it maintains its holding power across a vast temperature range.

The torque applied to the Q18518100T bolts creates a massive friction grip between the **Connection Plate** and the mating bracket. This friction, not the bolt shear strength, is the primary load-bearing mechanism for the **Balance Suspension Bracket Connection Plate**. If the bolts lose tension, the plate will shift, leading to fretting corrosion and elongation of the bolt holes. Therefore, the SPL nuts are essential guardians of the initial torque setting.

The bolts and nuts are coated with a specialized anti-corrosion layer to resist chemical attack from road salts. This plating ensures that the **Balance Suspension Bracket Connection Plate** fasteners can be removed and serviced years after installation, a key consideration for heavy equipment operating in remote and hostile environments where field maintenance is common.

Maintenance Protocol and Failure Prevention

Regular inspection of the **Balance Suspension Bracket Connection Plate** is a mandatory element of the CA3250P66K24L1TE5Z maintenance schedule. Mechanics should visually check the **Connection Plate** for signs of bending, distortion, or stress cracks originating from the bolt holes. Any damage to the **Balance Suspension Bracket Connection Plate** compromises the overall torsional rigidity of the chassis, leading to instability.

The critical maintenance step for the **Balance Suspension Bracket Connection Plate** is the torque check. Any visible “rust trails” or red dust around the bolt heads suggests that the friction grip has been compromised and the bolts are moving. Immediate re-torquing of the Q18518100T bolts is required. Since the nuts are SPL anti-loose nuts, the old ones should be replaced with new **SPL Hex Small Flange Anti-loose Nuts** (Part No. T32718TF2) to restore the full locking capability.

When replacing a damaged **Balance Suspension Bracket Connection Plate**, it is vital to ensure that the mating surfaces on the chassis are perfectly clean and flat. Any debris or rust scale will prevent the new plate from seating correctly, rendering the SPL nuts and flange bolts ineffective. Furthermore, only genuine FAW plates (Part No. 2919172-55R) should be used, as they possess the specific “55R” metallurgy required for arctic-grade impact resistance.

Using genuine fasteners ensures that the bolt length and head geometry match the original design, preventing interference with other suspension components. The reliability of the **Balance Suspension Bracket Connection Plate** is the assurance that the dump truck can perform its duties under the most severe conditions without structural failure.

Component Breakdown: Balance Suspension Bracket Connection Plate Logic

| No. |

Part Number |

Part Name |

Qty |

| 1 | T32718TF2 | SPL Hex Small Flange Anti-loose Nut | 8 |

| 2 | Q18518100T | Hexagon Head Flange Bolt | 8 |

| 3 | 2919172-55R | Connection Plate | 2 |

Conclusion: Structural Reliability Guaranteed

The Balance Suspension Bracket Connection Plate is an essential reinforcement member that ensures the structural integrity of the FAW J6P bogie. Its purpose is to prevent fatigue and tearing in the main chassis frame rails by distributing the heavy loads generated during off-road operation. The use of “55R” specification steel and the specialized T32718TF2 anti-loose nuts guarantees that the Balance Suspension Bracket Connection Plate maintains its rigidity even under extreme thermal and mechanical cycling in the Siberian environment.

For fleet operators, regular torque checks and visual inspection of the **Connection Plate** are vital for safety. By maintaining the integrity of this core component, you ensure the longevity of the entire **Balance Suspension Bracket Connection Plate** system and the continued operational efficiency of the CA3250P66K24L1TE5Z dump truck fleet.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.