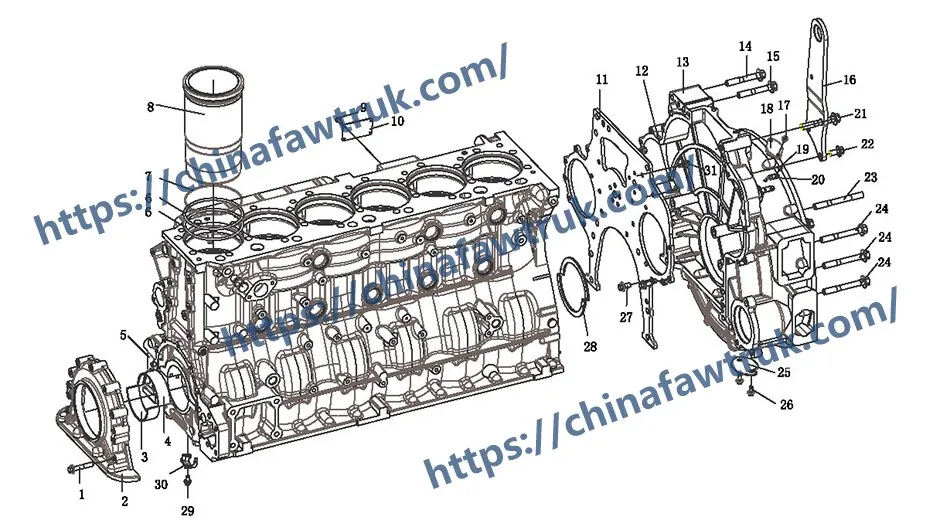

Welcome to this in-depth technical guide for the FAW Cylinder block assembly, the foundational power component for the FAW Jiefang CA4251P66K24T1A3E5 6×4 جرار نصف مقطورة ديزل. This document provides an essential, detailed analysis of the complete assembly and its associated parts.

This exploded view analysis is designed to deconstruct the entire FAW Cylinder block assembly, from its major structural castings and procured components down to the smallest serviceable units. We identify every bolt, ختم, تحمل, and plug, providing the clarity needed for complex service operations.

For technicians, engine rebuild specialists, ومديري قطع غيار الأسطول, this guide is an indispensable resource. A precise understanding of the FAW Cylinder block assembly is critical for accurate parts ordering, efficient maintenance, and ensuring the long-term reliability and peak performance of the engine.

At the heart of the entire powertrain is the ‘Cylinder Block Assembly’ (الجزء لا. 1002015-99ر). This single component serves as the engine’s skeletal backbone, housing all primary moving parts and providing the rigid structure needed to withstand immense combustion pressures. وهو جوهر FAW Cylinder block assembly.

Pressed into this main block are six ‘Cylinder Liners’ (1002016-81د). These are a prime example of a ‘smallest serviceable unit’. These liners are of a “بطانة مبللة” تصميم, meaning their outer surfaces are in direct contact with the engine’s coolant. This design provides superior heat transfer but relies on a precision seal.

This sealing is accomplished by the ‘O-ring Rubber Seals’ (1002017-81D and 1002019-81D). قائمة الأجزاء تدعو إلى 12 of one type and 6 of another, indicating a multi-seal-per-liner strategy to prevent high-pressure coolant from entering the oil sump, or combustion gases from entering the cooling system. Replacing these seals is a critical step during any engine overhaul of the FAW Cylinder block assembly.

The crankshaft is supported within the FAW Cylinder block assembly by a set of precision bearings. The parts list identifies seven ‘Upper Main Bearing Shells’ (1002031-81د) and seven ‘Lower Main Bearing Shells’ (1002032-81د). The upper shells are seated in the block itself, while the lower shells are seated in the main bearing caps (which were detailed in the previous block-only assembly). These shells are designed to support the crankshaft on a microscopic film of oil, preventing metal-to-metal contact.

In addition to rotational support, the crankshaft’s axial movement (forward and backward) must be precisely controlled. This is the job of the ‘Thrust Plates’ (1002036-53د). This set of four plates, or washers, is installed at a specific main bearing journal (typically the center one) to manage the thrust load generated by the clutch and helical-cut gears. Their thickness is critical, and wear on these components can lead to serious engine damage. This demonstrates the level of detail required when servicing the FAW Cylinder block assembly.

حرجة, and often overlooked, component within the modern heavy-duty FAW Cylinder block assembly is the ‘Piston Cooling Nozzle Assembly’ (1002210-81د). This parts list calls for six of these assemblies, one for each cylinder. The function of these nozzles is vital to the engine’s longevity and performance, especially under heavy load.

These nozzles are strategically positioned in the engine’s main oil gallery and are aimed at the underside of the piston crowns. When the engine is running, they spray a continuous, high-pressure jet of oil onto this extremely hot surface. This oil spray serves two primary purposes: firstly, it directly cools the piston, pulling heat away from the piston crown and ring lands. This prevents the piston from overheating, expanding excessively, and seizing in the cylinder liner.

ثانيًا, this cooling action prevents the oil in the piston ring grooves from coking (حرق) and turning to hard carbon. Coked rings will stick, leading to a loss of compression, excessive oil consumption, and high blow-by, which ultimately results in engine failure. لذلك, the proper function of these six nozzles is absolutely essential.

Each nozzle is secured to the block by a single ‘Bolt – مجموعة فوهة تبريد المكبس’ (1002214A53D-S). These six bolts are critical fasteners. The nozzles themselves often contain a check valve that only opens above a certain oil pressure, ensuring the engine’s main bearings are prioritized during start-up and at low idle, when oil pressure is at its lowest. خدمة FAW Cylinder block assembly requires careful inspection of these nozzles for blockage or damage.

ال FAW Cylinder block assembly must be sealed from the external environment and provide mounting points for various auxiliary systems. The ‘Crankshaft Front Oil Seal Seat’ (1002056-81د) is a key component that houses the front main seal, preventing oil from escaping the crankcase.

At the front of the engine, the ‘Gear Chamber Cover Plate’ (1002076-81د) seals the timing gear compartment. At the rear, a complex part listed as ‘Gear Chamber Cover-Flywheel Housing’ (1002061-1509) provides the structural link between the engine block and the transmission’s flywheel housing. Other components like the ‘Cover Plate-Flywheel Housing’ (1002067-29د) and ‘Pointer Flywheel Housing’ (1002066-29د) complete this assembly, the latter being used for setting engine timing.

مجمع معقد مثل FAW Cylinder block assembly is held together by a vast array of specialized fasteners. The parts list details numerous ‘Hex Flange Bolts’. These are categorized into ‘Fine Rod (نوع آر)’ (على سبيل المثال, Q1821055, Q18214130, Q18214120) and ‘Coarse Rod (نوع قياسي)’ (على سبيل المثال, س1841020, Q1841230, س1840816, Q1841025). This distinction is critical, as “نوع آر” bolts often have a specific shank design for precise alignment or shear strength, while standard bolts are used for general clamping.

The list also includes 12 ‘Stud Bolts’ (1002043-2000), which are typically used for high-temperature or high-stress mounting points like the exhaust or intake manifolds, allowing for more consistent clamping force. Other miscellaneous hardware includes the ‘Rear Lifting Lug’ (1002044-81د), the ‘Nameplate’ (1002091-29د) for identification, and the four ‘Nameplate Rivets’ (Q541026) to secure it to the block.

الجدول التالي يوفر كامل, detailed breakdown of all components identified in the ‘Cylinder Block Assembly’ رسم تخطيطي للجرار FAW CA4251P66K24T1A3E5. Use these part numbers for accurate ordering and service.

| علامة | الجزء لا. | جزء اسم | كمية |

|---|---|---|---|

| 1 | Q1821055 | سداسية شفة الترباس, Fine Rod (نوع آر) | 9 |

| 2 | 1002056-81د | العمود المرفقي مقعد ختم الزيت الأمامي | 1 |

| 3 | 1002032-81د | انخفاض قذيفة تحمل الرئيسية | 7 |

| 4 | 1002031-81د | غلاف المحمل الرئيسي العلوي | 7 |

| 5 | 1002015-99ر | تجميع كتلة الاسطوانة | 1 |

| 6 | 1002017-81د | يا الدائري الختم المطاطي | 12 |

| 7 | 1002019-81د | يا الدائري الختم المطاطي | 6 |

| 8 | 1002016-81د | بطانة الاسطوانة | 6 |

| 9 | Q541026 | Nameplate Rivet | 4 |

| 10 | 1002091-29د | لوحة | 1 |

| 11 | 1002076-81د | لوحة غطاء غرفة التروس | 1 |

| 12 | س1841020 | سداسية شفة الترباس, Coarse Rod (نوع قياسي) | 3 |

| 13 | 1002061-1509 | Gear Chamber Cover-Flywheel Housing | 1 |

| 14 | 1006056-53د-س | بولت – عمود تروس التوقيت المتوسط | 2 |

| 15 | Q18214110 | سداسية شفة الترباس, Fine Rod (نوع آر) | 3 |

| 16 | 1002044-81د | عروة الرفع الخلفية | 1 |

| 17 | Q1840612 | سداسية شفة الترباس, Coarse Rod (نوع قياسي) | 2 |

| 18 | 1002068-29د | سدادة – مبيت دولاب الموازنة | 1 |

| 19 | Q2140606 | الصليب راحة عموم رئيس المسمار | 2 |

| 20 | 1002066-29د | المؤشر – مبيت دولاب الموازنة | 1 |

| 21 | Q18214130 | سداسية شفة الترباس, Fine Rod (نوع آر) | 1 |

| 22 | Q1841230 | سداسية شفة الترباس, Coarse Rod (نوع قياسي) | 2 |

| 23 | 1002043-2000 | مسمار الترباس | 12 |

| 24 | Q18214120 | سداسية شفة الترباس, Fine Rod (نوع آر) | 10 |

| 25 | 1002067-29د | لوحة الغلاف – مبيت دولاب الموازنة | 1 |

| 26 | س1840816 | سداسية شفة الترباس, Coarse Rod (نوع قياسي) | 2 |

| 27 | Q1841025 | سداسية شفة الترباس, Coarse Rod (نوع قياسي) | 6 |

| 28 | 1002036-53د | Thrust Plate | 4 |

| 29 | 1002214A53D-S | بولت – مجموعة فوهة تبريد المكبس | 6 |

| 30 | 1002210-81د | مجموعة فوهة تبريد المكبس | 6 |

المواصفات ل FAW Cylinder block assembly are best understood in the context of its application. This is not just a single part, but a complex system of components, as detailed in this guide.

| تطبيق المركبة | فاو جيفانغ CA4251P66K24T1A3E5 6×4 جرار |

| مجموعة المكونات | Cylinder Block Assembly and Components |

| Parent Part Number | 1002015-99ر (تجميع كتلة الاسطوانة) |

| Cylinder Liners | 6 (الجزء لا. 1002016-81د), Wet-Liner Type |

| Main Bearing Shells | 7 العلوي (1002031-81د), 7 Lower (1002032-81د) |

| Piston Cooling System | 6x Piston Cooling Nozzle Assembly (1002210-81د) | Words

| Crankshaft Axial Control | 4x Thrust Plate (1002036-53د) |

| الوظيفة الأساسية | Houses all core engine components, including liners, العمود المرفقي, والمكابس. Manages internal lubrication and coolant flow. Forms the primary structure of the engine. |

أجزاء فاو, بما في ذلك مجموعة كتلة الأسطوانة, يتم تعبئتها بعناية لضمان الولادة الآمنة. يتم تأمين كل مكون في مواد واقية لمنع الضرر أثناء النقل. تضمن الشبكة اللوجستية الشحنات في الوقت المناسب في جميع أنحاء العالم, دعم عمليات الصيانة الفعالة. فيما يلي صورة توضح العبوة القياسية لقطع غيار شاحنات FAW, إظهار الاهتمام بالتفاصيل في التعامل والتخزين.

يقلل أسلوب التغليف هذا من مخاطر التآكل أو التلف الناتج عن الصدمات, ضمان وصول أجزاء مثل FAW Cylinder Block Assembly في حالة ممتازة. يمكن للعملاء الاعتماد على الخدمات اللوجستية التي تقدمها FAW للحصول على الجودة والموثوقية المتسقة.