FAW Russian Engine Side Panel: Optimizing 22 Strategic Components for Critical Arctic Thermal Shielding

The FAW Russian Engine Side Panel assembly is a vital environmental control system engineered for the FAW CA3250P66K24L1TE5Z dump truck. Operating in the extreme temperature gradients of the Russian North, these panels serve a dual purpose: they channel cooling airflow efficiently across the engine block while simultaneously shielding sensitive components from the corrosive onslaught of ice, mud, and road salts. By creating a controlled atmospheric zone within the engine bay, the FAW Russian Engine Side Panel logic assembly ensures optimal operating temperatures and reduces noise pollution, essential factors for vehicle longevity in mining environments.

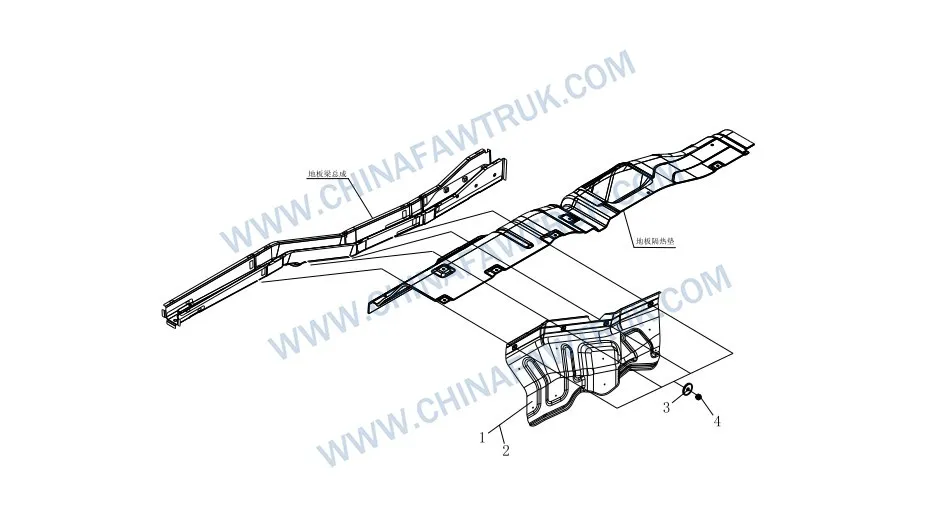

FAW Russian Engine Side Panel

| No. |

Part Number |

Part Name |

Qty |

| 1 |

5103611-72C |

Engine Left Side Panel |

1 |

| 2 |

5103612-72C |

Engine Right Side Panel |

1 |

| 3 |

Q40206 |

Large Washer |

10 |

| 4 |

CQ34006 |

Hexagon Nut |

10 |

Thermal Regulation and Material Durability

The primary functional components of the FAW Russian Engine Side Panel system are the Engine Left Side Panel (Part No. 5103611-72C) and the Engine Right Side Panel (Part No. 5103612-72C). These panels are not simple cosmetic covers; they are engineered thermal barriers. The “72C” suffix in the part numbers indicates a specific material formulation designed for the extreme cold of the Russian Arctic. Standard polymers often become brittle and crack when exposed to the rapid temperature fluctuations between the frozen exterior environment (-40°C) and the intense radiant heat of the diesel engine block (+90°C). The material used for the FAW Russian Engine Side Panel is a high-grade, fiber-reinforced composite that retains its ductility and structural integrity across this wide thermal spectrum.

The geometric design of the Engine Left Side Panel is sculpted to optimize airflow dynamics within the engine compartment. It works in conjunction with the radiator fan to channel air specifically over the hot side of the engine while shielding the sensitive electronic control units (ECUs) and wiring harnesses from direct heat soak. By maintaining a stable thermal envelope, the FAW Russian Engine Side Panel helps to prevent overheating during high-load climbing in summer and, conversely, retains necessary engine heat during idling in winter, aiding in cabin heating efficiency. This thermal management is critical for the fuel efficiency and emissions compliance of the CA3250 dump truck.

Furthermore, the Engine Right Side Panel provides a vital acoustic dampening function. The CA3250 is powered by a large-displacement diesel engine which generates significant noise. The composite structure of the FAW Russian Engine Side Panel absorbs high-frequency mechanical noise, preventing it from reflecting off the road surface and into the cabin or the surrounding environment. This reduction in noise pollution is not just a comfort feature but a safety requirement in many mining operations where clear communication is essential. The density and thickness of the panel material are calculated to maximize this sound attenuation property without adding unnecessary weight to the vehicle chassis.

Fastening Logic: The Large Washer System

Securing the composite panels to the steel chassis frame requires a specialized fastening strategy, centered around the extensive use of the Large Washer (Part No. Q40206). The assembly bill of materials calls for ten of these units, highlighting their importance in the FAW Russian Engine Side Panel system. Unlike standard small washers, the Large Washer has an expanded surface area that distributes the clamping load of the bolt over a much wider zone of the Engine Left Side Panel material. This is crucial when fastening softer composite materials; a standard washer would concentrate the force, leading to stress cracks or the bolt head pulling completely through the panel under vibration.

The use of the Large Washer also accommodates the differential thermal expansion rates between the steel mounting bolts and the composite Engine Right Side Panel. As the engine bay heats up, the plastic panel expands at a different rate than the steel frame. The wide bearing surface of the Large Washer allows for minute micro-movements without losing clamping pressure or inducing stress fractures around the mounting holes. This design consideration ensures that the FAW Russian Engine Side Panel remains securely attached through thousands of thermal cycles, preventing the annoying rattles and loose panels often seen on inferior trucks.

Additionally, the specific metallurgy of the Large Washer is chosen to resist corrosion. In the salt-laden environment of Russian winter roads, where chemical de-icers are sprayed heavily, fasteners are the first components to fail. These washers are typically treated with a zinc-chromate or similar protective coating to prevent rust formation. A corroded washer can seize to the bolt or the FAW Russian Engine Side Panel, making removal for engine service extremely difficult. The robust specification of the Large Washer ensures serviceability is maintained for the life of the vehicle.

Vibration Resistance: The Hexagon Nut Security

Completing the fastening architecture of the FAW Russian Engine Side Panel is the Hexagon Nut (Part No. CQ34006), also specified in a quantity of ten. These nuts act as the anchor points for the entire assembly. In a heavy-duty dump truck application, vibration is the enemy of all threaded connections. The Hexagon Nut selected for this application likely features a self-locking thread profile or is used in conjunction with a thread-locking compound to prevent backing out. Secure mounting of the Engine Left Side Panel is a safety critical issue; a loose panel falling into the rotating cooling fan or serpentine belt could cause catastrophic engine damage.

The standardized sizing of the Hexagon Nut (indicated by the ’06’ suffix, likely M6) ensures ease of maintenance. Fleet mechanics can remove and reinstall the Engine Right Side Panel using standard hand tools found in any basic toolkit. This accessibility is vital for daily pre-shift inspections where the driver needs to check oil levels or inspect belts located behind the panels. The FAW Russian Engine Side Panel design balances the need for secure, vibration-resistant retention with the practical requirement for quick, tool-free access in the field.

Furthermore, the interaction between the Hexagon Nut and the Large Washer creates a robust clamping sandwich that protects the mounting bosses of the FAW Russian Engine Side Panel. By placing the nut on the backside of a metal bracket or frame rail, and the washer on the composite side, the design ensures that torque is applied purely as tension on the bolt, rather than twisting force on the panel itself. This careful engineering prevents the common failure mode of cracked mounting tabs, ensuring the FAW Russian Engine Side Panel remains a durable shield for the engine compartment.

Debris Deflection and Component Protection

Beyond thermal and acoustic management, the FAW Russian Engine Side Panel acts as a physical armor for the engine bay. The Engine Left Side Panel is positioned to intercept road spray, mud, and gravel thrown up by the front tires. Without this barrier, the alternator, starter motor, and air compressor would be constantly coated in a layer of corrosive slurry. This is particularly devastating in winter when the slurry contains high concentrations of road salt. The FAW Russian Engine Side Panel effectively seals off the lower engine bay, significantly extending the service life of these expensive auxiliary components.

The Engine Right Side Panel performs a similar protective role for the turbocharger and exhaust manifold piping typically located on that side of the engine. Rapid cooling of a hot turbocharger housing by splashing ice water can cause thermal shock cracking. The FAW Russian Engine Side Panel prevents this direct contact, ensuring that thermal changes occur gradually. Additionally, the smooth inner surface of the panels prevents the accumulation of oil and dust, reducing the fire risk associated with oil-soaked debris building up around hot engine parts.

The durability of the FAW Russian Engine Side Panel material against chemical attack is also a key feature. Diesel fuel, engine oil, and hydraulic fluid spills are inevitable over the life of a truck. The composite material of the Engine Left Side Panel and Engine Right Side Panel is chemically inert to these hydrocarbon fluids, preventing softening, warping, or degradation. This chemical resistance ensures that the panels maintain their shape and protective function, keeping the engine bay of the CA3250 clean and orderly, which aids in leak detection and general maintenance.

Conclusion: Essential Protection for Arctic Operations

The FAW Russian Engine Side Panel logic assembly is a deceptively simple yet critically important component of the FAW CA3250 dump truck. It is the first line of defense against the harsh realities of the Russian environment. By combining the thermal and impact-resistant properties of the Engine Left Side Panel and Engine Right Side Panel with the robust security of the Large Washer and Hexagon Nut fastening system, FAW ensures that the engine operates in a protected, stable environment.

For fleet managers, maintaining the integrity of the FAW Russian Engine Side Panel is a low-cost, high-reward strategy. Replacing a cracked panel or a missing Hexagon Nut immediately restores the thermal and physical protection of the engine, preventing costly failures of auxiliary components down the line. By using genuine parts that meet the specific “72C” cold-weather specification, operators guarantee that their fleet remains resilient, efficient, and ready to tackle the toughest jobs on the frozen tundra.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.