FAW Russian Gearshift Guard: 4-Component Robust Shield for Superior Cabin Organization and Control

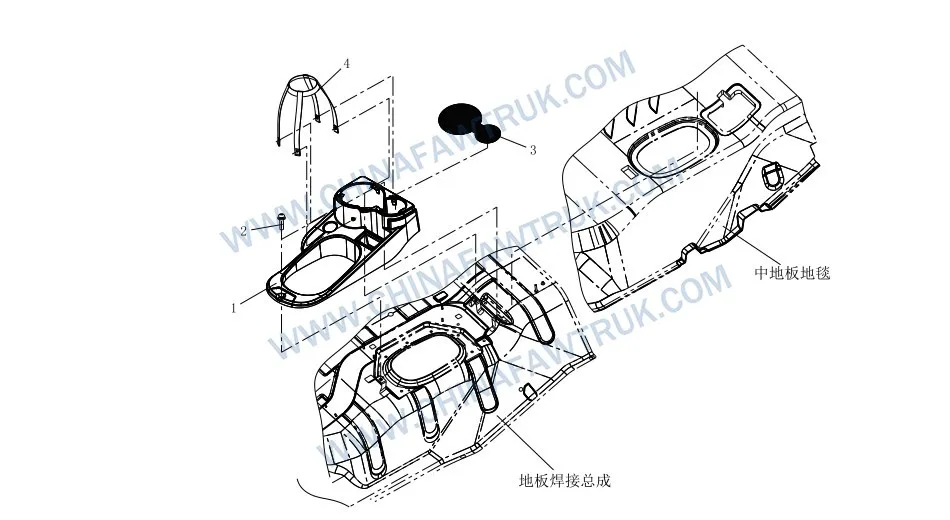

The FAW Russian Gearshift Guard assembly is the central console organizer and protective cowling for the CA3250P66K24L1TE5Z dump truck. Situated around the transmission shift lever, this assembly does more than hide the mechanical linkage; it provides a stable, ergonomic platform for the driver’s daily necessities. Engineered with cold-resistant polymers and integrated cup retention systems, the FAW Russian Gearshift Guard ensures that the control center remains clutter-free and hygienic, even when navigating the roughest mining terrain in the Russian Federation.

FAW Russian Gearshift Guard

| No. |

Part Number |

Part Name |

Qty |

| 1 | 5305010AD03 | Gearshift Guard Assembly | 1 |

| 2 | Q2360616F6 | Cross Recessed Pan Head Screw and Washer Assembly | 3 |

| 3 | 5305016-D03 | Cup Holder Anti-slip Mat | 1 |

| 4 | 5305020-D03 | Cup Holder Guard Strap Assembly | 1 |

Structural Integrity and Environmental Protection

The core of the FAW Russian Gearshift Guard is the Gearshift Guard Assembly (Part No. 5305010AD03). This main housing serves as the primary barrier between the cabin’s living space and the mechanical underpinnings of the transmission control system. In a dump truck application, the floor area around the gear stick is a common entry point for noise, heat, and potential dust ingress. The Gearshift Guard Assembly is precision-molded to fit tightly against the floor mat and the shift tower, creating a seal that helps maintain cabin pressure.

The material science behind the FAW Russian Gearshift Guard is dictated by the extreme temperature variations of the Russian market. The polymer used for the Gearshift Guard Assembly is likely an ABS or Polypropylene blend reinforced for impact resistance. Crucially, it must not become brittle at -40°C. A standard plastic guard could shatter if kicked by a heavy winter boot in freezing conditions. This component maintains its ductility, ensuring it can withstand the physical abuse of daily operations without cracking.

Furthermore, the surface finish of the Gearshift Guard Assembly is textured to resist scuffs and scratches. This area of the cabin sees high traffic and is often used as a dumping ground for miscellaneous items. The robust finish ensures that the interior maintains a professional appearance over time. By shielding the shift linkage from debris like dropped coins or food crumbs, the FAW Russian Gearshift Guard also plays a role in the mechanical longevity of the transmission controls.

Advanced Utility and Spill Prevention

Integrated into the FAW Russian Gearshift Guard is a thoughtful utility system centered on the cup holder. The Cup Holder Anti-slip Mat (Part No. 5305016-D03) is a removable rubber insert that sits at the bottom of the molded recess. Its function is two-fold: it dampens the vibration of a cup or bottle, preventing annoying rattles, and it provides a high-friction surface to stop beverages from sliding. In the bouncy environment of an off-road mine, this small component is essential for keeping liquids contained.

Complementing the mat is the Cup Holder Guard Strap Assembly (Part No. 5305020-D03). This component acts as a retention device for taller bottles or thermoses. In the FAW Russian Gearshift Guard design, this strap ensures that a heavy water bottle does not tip over during cornering or braking. A spilled drink in the center console area can be disastrous, potentially seeping into the transmission tunnel or damaging electrical connectors. The guard strap provides the necessary lateral support to prevent such accidents.

The design of the Cup Holder Anti-slip Mat also facilitates easy cleaning. Being removable, it can be taken out and washed to remove sticky residue from spilled coffee or soda. This contributes to the overall hygiene of the cabin. The FAW Russian Gearshift Guard transforms the area around the gear stick from a simple mechanical clearance zone into a functional, organized storage space that enhances the driver’s daily life.

Fastening Strategy and Vibration Control

The structural rigidity of the FAW Russian Gearshift Guard depends on its secure attachment to the floor tunnel. This is achieved using 3 units of the Cross Recessed Pan Head Screw and Washer Assembly (Part No. Q2360616F6). These fasteners are critical for isolating the plastic guard from the vibrating metal floor. The integrated washer distributes the clamping load over the plastic mounting tabs of the Gearshift Guard Assembly, preventing stress cracks that could lead to squeaks and rattles.

The “F6” designation on the screws indicates a corrosion-resistant coating. The floor area of a truck is frequently exposed to moisture from wet boots and melting snow. Standard screws would rust quickly in this environment, leaving unsightly stains and potentially seizing in the threaded holes. The FAW Russian Gearshift Guard fasteners are engineered to resist this corrosion, ensuring that the guard can be easily removed for transmission maintenance even after years of service.

Proper torque application is vital during installation. Over-tightening the Cross Recessed Pan Head Screw and Washer Assembly can crush the plastic of the Gearshift Guard Assembly, while under-tightening will allow the unit to vibrate. The FAW design likely incorporates metal sleeves or reinforced bosses within the plastic to act as limiters, ensuring the correct clamping force is achieved. This attention to fastening detail ensures that the console remains solid and silent.

Maintenance and Hygiene Protocols

Maintenance of the FAW Russian Gearshift Guard is primarily focused on cleanliness and inspection. The Gearshift Guard Assembly should be wiped down regularly with mild interior cleaner to remove dust and grime. Harsh solvents should be avoided as they can damage the surface finish. The Cup Holder Anti-slip Mat should be removed and washed frequently to prevent the buildup of bacteria and odors from spilled liquids.

Fleet mechanics should periodically check the tightness of the Cross Recessed Pan Head Screw and Washer Assembly fasteners. Vibration from the powertrain can cause screws to back out over time. A loose guard can rub against the shift lever boot, causing premature wear. Ensuring the FAW Russian Gearshift Guard is securely mounted protects both the trim piece and the mechanical components it covers.

If the Cup Holder Guard Strap Assembly becomes torn or the retention mechanism fails, it should be replaced. A non-functional strap allows bottles to become loose projectiles in the cabin. The modular nature of the FAW Russian Gearshift Guard allows for individual replacement of the mat and strap without needing to buy the entire main assembly, reducing long-term maintenance costs for the operator.

Conclusion: Organization Meets Durability

The FAW Russian Gearshift Guard assembly is a compact but essential part of the J6P cabin environment. Comprising just 4 distinct components, it delivers outsized value by protecting the transmission linkage, organizing driver essentials, and enhancing the overall aesthetic of the interior. Its robust construction is tailored to survive the harsh realities of the Russian transport sector.

For fleet managers, the state of the gearshift console is often a reflection of the overall care taken of the vehicle. A clean, secure, and functional FAW Russian Gearshift Guard contributes to a positive driver experience. By maintaining these components with genuine FAW parts, operators ensure that the cabin remains a safe, organized, and professional workspace for the long haul.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.