FAW Russian Three-Tier Step Logic: The Structural Gateway Providing Safe Egress in Arctic Operations

The FAW Russian Three-Tier Step assembly is a critical ergonomic interface designed for the CA3250P66K24L1TE5Z dump truck. In the frozen landscape of the Russian Federation, where drivers wear heavy insulated boots and bulky gear, safe cabin access is paramount. This assembly integrates the third and final step level directly into the vehicle’s upper fender architecture, bridging the gap between the chassis ladders and the cab floor. Engineered to bear significant static and dynamic loads while resisting ice accumulation, the FAW Russian Three-Tier Step ensures reliable footing for operators in the most hazardous mining environments.

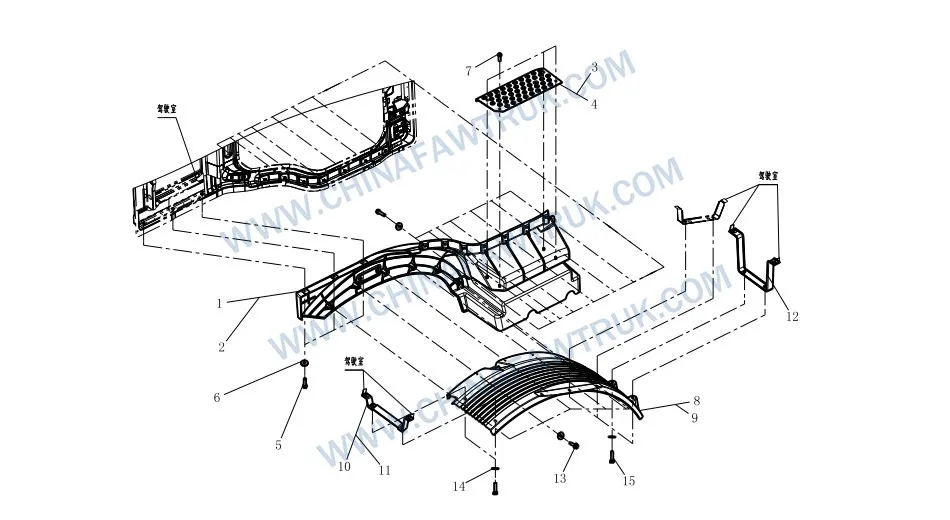

FAW Russian Three-Tier Step

| No. |

Part Number |

Part Name |

Qty |

| 1 | 5103121-B35 | Left Upper Fender | 1 |

| 2 | 5103122-B35 | Right Upper Fender (See 5103121-B35) | 1 |

| 3 | 5103191BA01 | Left Third-Level Step Plate | 1 |

| 4 | 5103192BA01 | Right Third-Level Step Plate (See 5103191BA01) | 1 |

| 5 | CQ1420625F6 | Combination Bolt | 20 |

| 6 | Q40206F6 | Large Washer | 20 |

| 7 | Q2360612F6 | Cross Recessed Pan Head Screw and Washer Assembly | 8 |

| 8 | 5103161-B35 | Left Upper Mudguard | 1 |

| 9 | 5103162-B35 | Right Upper Mudguard (See 5103161-B35) | 1 |

| 10 | 5103145-B35 | Left Upper Mudguard Rear Bracket Assembly | 1 |

| 11 | 5103150-B35 | Right Upper Mudguard Rear Bracket Assembly | 1 |

| 12 | 5103140-A01 | Upper Mudguard Front Bracket Assembly (See 5103141-A01) | 2 |

| 13 | CQ1460616 | Combination Bolt | 12 |

| 14 | Q40206 | Large Washer | 24 |

| 15 | CQ1420620 | Combination Bolt | 12 |

Ergonomic Design for Arctic Accessibility

The design philosophy behind the FAW Russian Three-Tier Step focuses intensely on human factors engineering tailored for the heavy transport sector. In the Russian Arctic, drivers are often encased in multiple layers of thermal clothing and wear heavy, cleated boots that reduce dexterity and tactile feedback. The FAW Russian Three-Tier Step addresses this by providing a wide, stable platform that accommodates the increased footprint of winter footwear. The Left Third-Level Step Plate (Part No. 5103191BA01) serves as the final transition point into the cabin, positioned at an optimal height to reduce the physical effort required to lift the body into the driver’s seat.

Safety in ingress and egress is a primary concern in mining operations, where slip-and-fall accidents are a leading cause of injury. The FAW Russian Three-Tier Step features an aggressive, open-grid tread pattern stamped directly into the polymer or metal structure. This design is self-cleaning; as the driver steps onto the plate, the pressure forces snow, mud, and slush through the open grating, ensuring that the boot contacts the traction surface rather than a layer of ice. The FAW Russian Three-Tier Step effectively prevents the build-up of a “glaze” that often renders solid metal steps treacherous in freezing conditions.

Furthermore, the positioning of the FAW Russian Three-Tier Step within the fender assembly is calculated to protect it from road spray while the vehicle is in motion. By recessing the step slightly within the Left Upper Fender (Part No. 5103121-B35) contour, the design minimizes the accumulation of road grime on the tread surface. This passive protection ensures that when the driver stops to exit the vehicle, the FAW Russian Three-Tier Step is clean and ready for use, reducing the maintenance burden on the operator to constantly chip away ice before climbing down.

Structural Integration with Fender Architecture

The FAW Russian Three-Tier Step is not a standalone accessory but an integral part of the vehicle’s upper bodywork system. It is mechanically bonded to the Left Upper Fender and supported by a robust sub-structure of brackets, including the Upper Mudguard Front Bracket Assembly (Part No. 5103140-A01). This integration ensures that the step is not merely hanging from the plastic fender but is anchored to the chassis’s structural hard points. The FAW Russian Three-Tier Step is designed to transfer the vertical load of a heavy driver directly into these steel supports, bypassing the cosmetic plastic skin to prevent stress cracking.

The interaction between the FAW Russian Three-Tier Step and the Right Upper Fender (Part No. 5103122-B35) on the passenger side mirrors this robust construction. In the Russian market, where co-drivers or site managers frequently ride along, the passenger-side access is just as critical. The symmetry of the FAW Russian Three-Tier Step design simplifies parts inventory for fleet managers, as the fastening hardware and bracket logic remain consistent across both sides of the vehicle.

Additionally, the assembly includes the Left Upper Mudguard (Part No. 5103161-B35) and Right Upper Mudguard (Part No. 5103162-B35), which act as splash shields behind the steps. These components prevent mud thrown by the tires from impacting the back of the step structure or entering the cab air vents. The FAW Russian Three-Tier Step system functions as a cohesive unit where the mudguard protects the step, and the step reinforces the fender, creating a durable assembly capable of withstanding the high-vibration environment of a dump truck.

Fastening Strategy and Load Distribution

The structural integrity of the FAW Russian Three-Tier Step is secured by a high-density fastening arrangement. The assembly utilizes 20 units of the Combination Bolt (Part No. CQ1420625F6) to clamp the step plates and fender panels to the underlying brackets. This high bolt count is a deliberate engineering choice for the FAW Russian Three-Tier Step. It ensures that the load applied by a driver jumping onto the step is distributed across a wide area, preventing point-loading that could fatigue the mounting tabs or strip the threads in the support brackets.

To further enhance durability, the system employs Large Washer (Part No. Q40206F6) units at every critical fastening point. These washers increase the effective clamping surface area by several factors compared to standard washers. In the context of the FAW Russian Three-Tier Step, which involves bolting through thermoplastic materials, these large washers are essential. They prevent the bolt heads from “creeping” or sinking into the plastic over time due to thermal cycling and vibration, ensuring that the step remains rigidly attached even after years of service in extreme temperature fluctuations.

The fasteners themselves are treated with a high-grade corrosion-resistant coating, indicated by the “F6” suffix. This is crucial for the FAW Russian Three-Tier Step, which is located in the wheel spray zone and constantly exposed to road salts. Standard fasteners would quickly rust solid, making it impossible to replace a damaged step plate without destructive methods. The use of corrosion-resistant hardware ensures that the FAW Russian Three-Tier Step remains serviceable, allowing for quick component swaps in the field.

Maintenance and Inspection Protocol

For fleet operators, the FAW Russian Three-Tier Step is a safety-critical item that requires regular inspection. Drivers should be trained to visually check the step daily for cracks, loose bolts, or accumulated ice that could compromise traction. The open-grid design of the FAW Russian Three-Tier Step facilitates quick visual checks of the mounting brackets underneath without requiring disassembly. Any movement or “play” in the step when weight is applied indicates loose hardware that must be re-torqued immediately to prevent bracket failure.

Impact damage is a common occurrence for the FAW Russian Three-Tier Step in mining environments. If the step plate is bent or the surrounding Left Upper Fender is cracked, the structural integrity of the access system is compromised. The modular design allows for the individual replacement of the Left Third-Level Step Plate without replacing the entire fender assembly, providing a cost-effective repair solution. Fleet managers should keep spare step plates and the associated Combination Bolt hardware in stock to address these common issues promptly.

Cleaning the FAW Russian Three-Tier Step is also part of essential maintenance. While self-cleaning, the grid can eventually become clogged with dried clay or tar. Pressure washing the steps during routine vehicle cleaning ensures that the anti-slip properties are maintained. Avoiding the buildup of corrosive materials on the FAW Russian Three-Tier Step brackets also extends the life of the metal components, preserving the safety and functionality of the driver’s entry system for the lifespan of the truck.

Conclusion: The First Step to Safety

The FAW Russian Three-Tier Step assembly is a vital component that directly impacts the daily safety and comfort of the operator. By providing a secure, engineered platform for cabin access, it mitigates the risks associated with working in the extreme conditions of the Russian heavy transport sector. The robust integration of the step plates with the fender architecture and the use of heavy-duty fastening hardware demonstrate FAW’s commitment to durability.

For fleet managers, prioritizing the maintenance of the FAW Russian Three-Tier Step is a direct investment in workforce welfare. Ensuring that every entry and exit is safe reduces accident rates and improves driver confidence. By utilizing genuine replacement parts and adhering to inspection protocols, operators can ensure that this essential interface between man and machine remains reliable, regardless of the weather or terrain.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.