FAW Russian Upper Mudguard Assembly: The multi-layered Polymer Shield Defending Against Arctic Road Debris

The FAW Russian Upper Mudguard assembly serves as the primary barrier between the CA3250P66K24L1TE5Z dump truck’s cabin and the punishing road environment. Designed specifically for the Russian Federation, this assembly integrates aerodynamic styling with heavy-duty protection. It shields vital door mechanisms and structural pillars from the corrosive slurry of ice and salt found on mining haul roads. By deflecting high-velocity debris, the FAW Russian Upper Mudguard ensures the longevity of the vehicle’s bodywork in extreme cold.

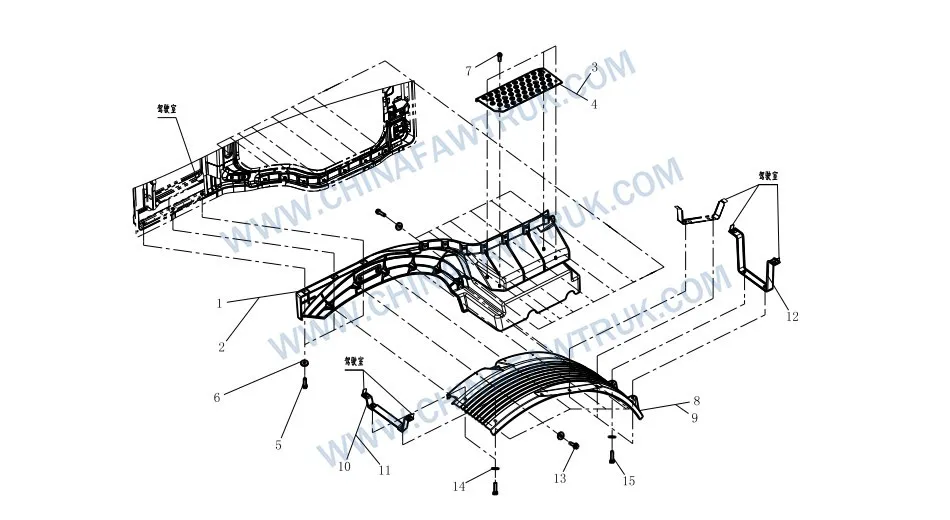

FAW Russian Upper Mudguard

| No. |

Part Number |

Part Name |

Qty |

| 1 | 5103121-B35 | Left Upper Fender | 1 |

| 2 | 5103122-B35 | Right Upper Fender | 1 |

| 3 | 5103191BA01 | Left Third-Level Step Plate | 1 |

| 4 | 5103192BA01 | Right Third-Level Step Plate | 1 |

| 5 | CQ1420625F6 | Combination Bolt | 20 |

| 6 | Q40206F6 | Large Washer | 20 |

| 7 | Q2360612F6 | Cross Recessed Pan Head Screw and Washer Assembly | 8 |

| 8 | 5103161-B35 | Left Upper Mudguard | 1 |

| 9 | 5103162-B35 | Right Upper Mudguard | 1 |

| 10 | 5103145-B35 | Left Upper Mudguard Rear Bracket Assembly | 1 |

| 11 | 5103150-B35 | Right Upper Mudguard Rear Bracket Assembly | 1 |

| 12 | 5103140-A01 | Upper Mudguard Front Bracket Assembly | 2 |

| 13 | CQ1460616 | Combination Bolt | 12 |

| 14 | Q40206 | Large Washer | 24 |

| 15 | CQ1420620 | Combination Bolt | 12 |

Material Science and Arctic Polymer Performance

The durability of the FAW Russian Upper Mudguard hinges on the selection of advanced thermoplastic materials tailored for extreme cold. The primary aerodynamic panels, including the Left Upper Fender (Part No. 5103121-B35) and Right Upper Fender (Part No. 5103122-B35), are molded from a modified high-density polyethylene (HDPE) or TPO blend. This material is specifically engineered to maintain a low glass transition temperature, ensuring that the fender retains its flexibility even when the ambient temperature drops below -40°C. In the mining sector, this ductility prevents catastrophic shattering upon impact with frozen berms or rocks.

Beneath these cosmetic skins, the assembly utilizes functional liners like the Left Upper Mudguard (Part No. 5103161-B35) and Right Upper Mudguard (Part No. 5103162-B35). These inner components are designed with a hydrophobic surface texture that actively sheds water and mud. Preventing “mud packing” is critical in Russian operations, where accumulated slush can freeze into heavy blocks that weigh down the assembly and corrode metal sub-structures. The self-cleaning nature of the FAW Russian Upper Mudguard liners mitigates this risk effectively.

The polymer formulation also includes high levels of UV stabilizers to combat the intense solar reflection experienced in snow-covered landscapes. Without this protection, standard plastics would degrade and chalk within a single season. The FAW Russian Upper Mudguard maintains its structural integrity and colorfastness over years of exposure, ensuring the vehicle retains its professional appearance.

Finally, the integration of these polymer panels is secured by precision-molded trim fasteners like the Cross Recessed Pan Head Screw and Washer Assembly (Part No. Q2360612F6). These screws are coated to resist rust stains, ensuring that the visual quality of the FAW Russian Upper Mudguard is preserved. The combination of advanced materials and specialized hardware creates a system that is both tough and aesthetically resilient.

Heavy-Duty Structural Bracketry

Supporting the lightweight skin of the FAW Russian Upper Mudguard is a robust skeleton of steel brackets. The forward attachment point is managed by the Upper Mudguard Front Bracket Assembly (Part No. 5103140-A01), which acts as a flexible interface between the cab and the fender. This bracket is designed with a specific yield point to absorb vibration energy, decoupling the rigid fender from the high-frequency tremors of the chassis. This isolation prevents stress cracks from forming at the mounting tabs of the plastic panels.

The rear section requires substantial support due to its cantilevered design. The Left Upper Mudguard Rear Bracket Assembly (Part No. 5103145-B35) and Right Upper Mudguard Rear Bracket Assembly (Part No. 5103150-B35) provide this necessary rigidity. Fabricated from heavy-gauge steel, these brackets are treated with a hot-dip galvanization or e-coating process to resist the aggressive corrosion found in the wheel well environment. The FAW Russian Upper Mudguard relies on these brackets to maintain its shape under heavy loads of ice and mud.

Alignment is another critical function of the bracket system. The rear brackets feature slotted mounting holes that allow technicians to fine-tune the position of the fender relative to the door and cab side. Proper alignment ensures a tight seal against wind noise and water ingress. The FAW Russian Upper Mudguard engineering allows for these adjustments to be made easily during assembly or after minor impact repairs.

The interaction between the steel brackets and the polymer panels is managed by localized reinforcement zones. Where the brackets attach to the fender, the plastic is thickened to prevent pull-through. This thoughtful engineering ensures that the FAW Russian Upper Mudguard remains securely attached even when subjected to the intense G-forces of off-road driving on washboard surfaces.

Integrated Access System: The Third-Level Step

A key functional element of the FAW Russian Upper Mudguard is the integration of the driver’s entry system. The assembly includes the Left Third-Level Step Plate (Part No. 5103191BA01) and Right Third-Level Step Plate (Part No. 5103192BA01), which bridge the gap between the chassis steps and the cabin floor. These are not simple cosmetic additions; they are structural components designed to bear the full weight of a driver wearing heavy winter gear, transferring the load directly into the steel sub-frame.

Safety is paramount in the design of these steps. The surface features an aggressive, open-grid anti-slip tread pattern. In the icy conditions of a Siberian mine, a solid metal step would become a dangerous slide. The open design of the FAW Russian Upper Mudguard step allows snow and mud to be pushed through the holes by the driver’s boot, ensuring positive traction is always available. This self-cleaning feature significantly reduces workplace injuries during ingress and egress.

The steps are secured using a high density of fasteners, specifically 20 units of the Combination Bolt (Part No. CQ1420625F6). This redundancy ensures that the load is evenly distributed across the interface between the step and the fender structure. Even if several bolts were to loosen due to extreme vibration, the step remains secure. The FAW Russian Upper Mudguard prioritizes human safety by over-engineering this critical touchpoint.

Furthermore, the placement of the steps within the fender assembly is ergonomically calculated. The height and depth of the step align with natural human movement, reducing strain on the driver’s knees and back. This consideration is vital for operators who may climb in and out of the cab dozens of times a day. The FAW Russian Upper Mudguard combines structural utility with ergonomic design to support the daily workflow of the driver.

Fastening Strategy and Maintenance Protocols

The longevity of the FAW Russian Upper Mudguard is heavily dependent on its specialized fastening hardware. The assembly utilizes various Combination Bolt types (Part Nos. CQ1460616 and CQ1420620), which feature integrated captive washers. These washers prevent the bolt heads from rotating directly against the soft plastic or painted surfaces, eliminating galling and subsequent rust streaks. The use of combination bolts also speeds up assembly and ensures consistent clamping force across the entire unit.

Crucially, the assembly incorporates Large Washer (Part Nos. Q40206F6 and Q40206) in high-stress areas. These wide-flange washers increase the effective clamping area by over 300% compared to standard washers. This distributes the bolt load over a broad section of the plastic fender, preventing stress concentrations that would otherwise cause the material to crack or “flow” under pressure. In the extreme cold, where plastic is most vulnerable, these large washers are the key to the durability of the FAW Russian Upper Mudguard.

The fasteners themselves feature an “F6” corrosion-resistant coating, typically a zinc-flake or Geomet treatment. This ensures that the bolts do not seize in the cage nuts, allowing the FAW Russian Upper Mudguard to be easily disassembled for service even after years of exposure to road salts. Standard zinc-plated bolts would rust solid in a single winter, turning a simple panel replacement into a destructive removal process.

Maintenance of the FAW Russian Upper Mudguard involves regular visual inspections for loose hardware and stress cracks. Fleet operators should prioritize checking the tightness of the step plate bolts and the main bracket-to-cab bolts during routine service. Any damaged panels should be replaced promptly to prevent secondary damage to the cab paint. By utilizing genuine FAW replacement parts, including the correct large washers and coated bolts, operators ensure that the assembly continues to provide optimal protection.

Conclusion: The Armor of the Arctic

The FAW Russian Upper Mudguard assembly is a sophisticated integration of materials science, structural engineering, and safety design. Comprising 15 distinct components, from impact-resistant polymer skins to heavy-duty steel brackets and specialized load-spreading fasteners, it forms a cohesive shield against the elements. It protects the truck’s vital systems from corrosion and impact while providing a safe, reliable entry point for the driver.

For fleet managers, the FAW Russian Upper Mudguard represents a commitment to vehicle longevity and operator safety. Neglecting this assembly can lead to accelerated cab corrosion, door failures, and potential driver injuries. By maintaining this system with genuine parts and regular inspections, operators ensure that their fleet remains professional, functional, and ready to face the extreme challenges of the Russian heavy transport sector.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.