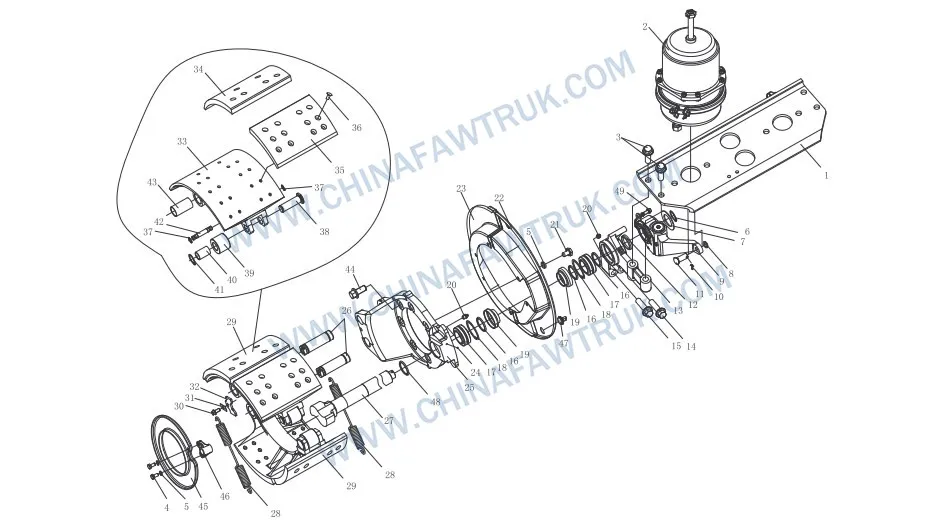

FAW Russian Rear Right Brake Assembly: Deconstructing 50 Strategic Components for Balanced Arctic Performance

The FAW Russian Rear Right Brake assembly is the complementary force in the CA3250P66K24L1TE5Z dump truck’s rear deceleration system. As the final node in the pneumatic circuit, this brake unit demands precise timing and force application to prevent yaw instability during emergency stops on icy Russian roads. Built with cold-resistant metallurgy and reinforced friction linings, the FAW Russian Rear Right Brake operates seamlessly in temperatures as low as -50°C. This guide provides a detailed breakdown of the S-cam geometry, automatic adjustment mechanisms, and critical mounting hardware that constitute the FAW Russian Rear Right Brake.

FAW Russian Rear Right Brake

| No. |

Part Number |

Part Name |

Qty |

| 1 | 3502126A483 | Support Plate – Spring Brake Cylinder | 1 |

| 2 | 3530030-896-C00 | Rear Axle Right Spring Cylinder with Quick Connector Assy | 1 |

| 3 | 3502038-1H | Locking Bolt – For Fastening Rear Brake Bracket | 4 |

| 4 | CQ1500816 | Hexagon Head Bolt | 4 |

| 5 | Q40308 | Spring Washer | 16 |

| 6 | Q43138 | Shaft Snap Ring | 2 |

| 7 | 3501156A392 | Brake Adjustment Shim | 2 |

| 8 | Q40114 | Washer | 2 |

| 9 | 3502210-A0E | Rear Axle Right Automatic Adjuster Arm Assy | 1 |

| 10 | Q5003025 | Cotter Pin | 2 |

| 11 | Q5101438 | Flat Head Pin | 2 |

| 12 | 3502123-A0E | Spacer – Camshaft Bracket | 2 |

| 13 | 3502128-A0E | Rear Axle Right Camshaft Bracket | 1 |

| 14 | 3503038-A0E | Locking Bolt – Camshaft Bracket | 2 |

| 15 | 3503039-A0E | Locking Bolt – Camshaft Bracket | 2 |

| 16 | 3502153-A0E | Oil Seal – Camshaft Bracket | 6 |

| 17 | 3502135-A0E | Camshaft Joint Bearing Assembly | 4 |

| 18 | Q43062 | Hole Snap Ring | 4 |

| 19 | 3502124-A0E | Seat – Oil Seal | 4 |

| 20 | CQ70001 | Straight Grease Fitting | 4 |

| 21 | CQ1500812 | Hexagon Head Bolt | 12 |

| 22 | 3502031-A0E | Rear Brake Rear Dust Shield | 2 |

| 23 | 3502032-A0E | Rear Brake Front Dust Shield | 2 |

| 24 | Q966555 | Steel Ball | 2 |

| 25 | 3502021-A0E | Rear Brake Bracket | 2 |

| 26 | 3502086-A6E | Rear Brake Shoe Axle / Anchor Pin | 4 |

| 27 | 3502152-A6E | Rear Right Brake Camshaft | 1 |

| 28 | 3502436-A0E | Return Spring | 4 |

| 29 | 3502375-A6E | Rear Brake Shoe with Roller Assembly | 4 |

| 30 | CQ1501016 | Hexagon Head Bolt | 2 |

| 31 | 3501087-4E | Lock Plate – Brake Shoe Axle Retainer Bolt | 2 |

| 32 | 3502087-A6E | Brake Shoe Axle Retainer Plate | 2 |

| 33 | 3502391-A6E | Rear Brake Shoe | 4 |

| 34 | 3502406-A6E | Rear Friction Lining I | 4 |

| 35 | 3502407-A6E | Rear Friction Lining II | 4 |

| 36 | 3502408-A0E | Rivet – Brake Lining | 104 |

| 37 | Q43112 | Shaft Snap Ring | 8 |

| 38 | 3502394-A0E | Roller Shaft | 4 |

| 39 | 3502392-A0E | Brake Shoe Roller | 4 |

| 40 | 3502393-A0E | Roller Bushing | 4 |

| 41 | Q43122 | Shaft Snap Ring | 4 |

| 42 | 3502398-A0E | Return Spring Anchor Pin | 4 |

| 43 | 3501396-A0S | Bushing – Brake Shoe | 4 |

| 44 | 3502038-487 | Locking Bolt – Brake Bracket | 14 |

| 45 | 3502434AA0E | Dust Shield II (ABS) | 2 |

| 46 | 3605366-93W | Rear Wheel Speed Sensor Bracket | 2 |

| 47 | 3501034-02 | Plug – Dust Shield Inspection Hole | 4 |

| 48 | 3501029-A0S | Oil Seal – Brake Camshaft | 2 |

| 49 | CQ1500820 | Hexagon Head Bolt | 2 |

| – | Q40308 | Spring Washer | 2 |

Robust Friction Architecture for Severe Loads

The FAW Russian Rear Right Brake distinguishes itself with a significantly robust friction coupling designed for the tandem drive axles. The assembly utilizes 410mm diameter drums coupled with the massive Rear Brake Shoe (Part No. 3502391-A6E). Unlike the front axle, the rear shoes carry a much larger surface area of friction material, split into Rear Friction Lining I (Part No. 3502406-A6E) and Rear Friction Lining II (Part No. 3502407-A6E). This segmented design prevents thermal stress cracking by allowing for differential expansion across the lining surface during prolonged braking events in the Russian tundra.

Structural rigidity is paramount. The Rear Brake Bracket (Part No. 3502021-A0E) serves as the anchor point, bolted directly to the axle housing with high-tensile Locking Bolt – For Fastening Rear Brake Bracket (Part No. 3502038-1H). This bracket must withstand torque loads exceeding 25,000 Nm without deflection. The Rear Brake Shoe Axle / Anchor Pin (Part No. 3502086-A6E) provides the pivot point for the shoes. In this heavy-duty specification, these pins are hardened to resist ovalization, ensuring that the brake geometry remains precise over hundreds of thousands of kilometers.

Retention of the friction components is managed by the Return Spring (Part No. 3502436-A0E). These springs are critical for dragging the heavy shoes away from the drum immediately after the pedal is released. In the FAW Russian Rear Right Brake, these springs are cadmium-plated to resist corrosion from road salts used on icy Russian highways. Failure of these springs leads to brake drag, overheating, and potentially wheel-end fires, making their inspection a priority during maintenance.

Camshaft Actuation and Adjustment Logic

The actuation force in the FAW Russian Rear Right Brake is delivered through the Rear Right Brake Camshaft (Part No. 3502152-A6E). This component features a reverse-helix S-profile, specifically machined to actuate the right-side shoes against the drum’s rotation. It is supported by a sophisticated bearing system involving the Camshaft Joint Bearing Assembly (Part No. 3502135-A0E). This spherical bearing design accommodates slight axle flex under heavy loads without binding the camshaft, a common failure mode in rigid bearing designs.

Driving the camshaft is the Rear Axle Right Automatic Adjuster Arm Assy (Part No. 3502210-A0E). This Haldex-style adjuster senses the clearance between the lining and the drum on every stroke. If the gap exceeds the factory specification due to wear, the internal worm gear ratchets forward, maintaining optimal braking efficiency. This automatic adjustment is crucial for the FAW Russian Rear Right Brake, as manual adjustment of 8 rear wheel positions in -40°C weather is both impractical and dangerous.

The interface between the S-cam and the shoes is smoothed by the Rear Brake Shoe with Roller Assembly (Part No. 3502375-A6E). This assembly includes the Brake Shoe Roller (Part No. 3502392-A0E) and Roller Shaft (Part No. 3502394-A0E). These rollers reduce mechanical hysteresis, ensuring that the brakes apply and release linearly with pedal pressure. The Roller Bushing (Part No. 3502393-A0E) is internally lubricated, preventing the roller from seizing and flat-spotting, which would cause a pulsating brake pedal.

Sealing and Environmental Defense

Operating in the muddy, gritty environment of a mine site requires exceptional sealing. The FAW Russian Rear Right Brake features a multi-barrier defense system. The primary barrier is the Rear Brake Rear Dust Shield (Part No. 3502031-A0E) and Rear Brake Front Dust Shield (Part No. 3502032-A0E). These stamped steel shields interlock to encase the drum, preventing rocks from entering and damaging the friction surfaces. The inspection ports are sealed with the Plug – Dust Shield Inspection Hole (Part No. 3501034-02), allowing for quick visual checks without disassembly.

Internal contamination is prevented by the Oil Seal – Camshaft Bracket (Part No. 3502153-A0E). This double-lipped seal keeps the chassis grease inside the camshaft bracket and prevents water ingress. A failure here would allow water to wash away the lubricant, leading to camshaft corrosion and seizure. The assembly also uses the Seat – Oil Seal (Part No. 3502124-A0E) to position the seal correctly, ensuring consistent lip pressure on the shaft regardless of thermal expansion.

Even the smaller components are designed for retention. The Lock Plate – Brake Shoe Axle Retainer Bolt (Part No. 3501087-4E) acts as a mechanical fuse, preventing the anchor pins from backing out under vibration. The use of multiple Shaft Snap Ring (Part No. Q43112) units ensures that the roller shafts and pivot pins remain captive. This attention to detail prevents catastrophic disassembly of the FAW Russian Rear Right Brake during operation.

Maintenance and Power Application

The brute force required to actuate the rear brakes is provided by the Rear Axle Right Spring Cylinder with Quick Connector Assy (Part No. 3530030-896-C00). This dual-chamber actuator provides both service braking via air pressure and parking/emergency braking via a powerful internal spring. It is mounted to the Support Plate – Spring Brake Cylinder (Part No. 3502126A483). This heavy-gauge plate prevents the cylinder from flexing under load, ensuring that 100% of the pushrod force is directed into the slack adjuster.

Maintenance access is facilitated by the Straight Grease Fitting (Part No. CQ70001). Located on the camshaft brackets and the slack adjuster, these fittings allow mechanics to purge old, contaminated grease and replace it with fresh low-temperature lubricant. The Brake Adjustment Shim (Part No. 3501156A392) allows for fine-tuning of the camshaft end-play. Excessive end-play causes the S-cam to walk laterally, leading to uneven lining wear. Correct shimming is a critical step in rebuilding the FAW Russian Rear Right Brake.

Finally, the integration of ABS is supported by the Rear Wheel Speed Sensor Bracket (Part No. 3605366-93W). This bracket positions the sensor within millimeters of the tone ring. A stable bracket is essential for preventing sensor drop-out signals which would trigger ABS fault codes. By maintaining the FAW Russian Rear Right Brake with genuine components like the Rivet – Brake Lining (Part No. 3502408-A0E), operators ensure that the vehicle remains compliant with safety regulations and capable of stopping safely in any condition.

Conclusion: The Backbone of Heavy Haulage

The FAW Russian Rear Right Brake is a masterpiece of heavy-duty engineering, comprised of 50 strategic components working in concert. From the massive clamping force of the Rear Axle Right Spring Cylinder to the precise modulation of the Rear Right Brake Camshaft, every element is designed for durability and safety. The robust sealing and automatic adjustment features minimize downtime and maximize operational efficiency in the harshest environments on earth.

For fleet owners, the path to reliability lies in using genuine parts. Substituting critical items like the Rear Brake Shoe or the Return Spring with inferior aftermarket alternatives compromises the safety of the entire vehicle. By adhering to the specifications outlined in this breakdown of the FAW Russian Rear Right Brake, operators invest in the long-term performance and safety of their fleet.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.