FAW Russian Auxiliary Air Tank Assembly: Deconstructing 20 Strategic Components for Reserve Pneumatic Power

The FAW Russian Auxiliary Air Tank assembly is the definitive backup energy reservoir for the FAW CA3250P66K24L1TE5Z dump truck. Engineered explicitly for the sub-zero operational theaters of Siberia, this assembly guarantees that critical braking pressure remains available even during periods of high demand or compressor latency. By implementing the complete FAW Russian Auxiliary Air Tank system, operators ensure a complex network of dual-chamber storage and high-pressure distribution functions as a cohesive safety backbone. This guide deconstructs why the FAW Russian Auxiliary Air Tank is critical for heavy-duty vehicle survival in the frozen north.

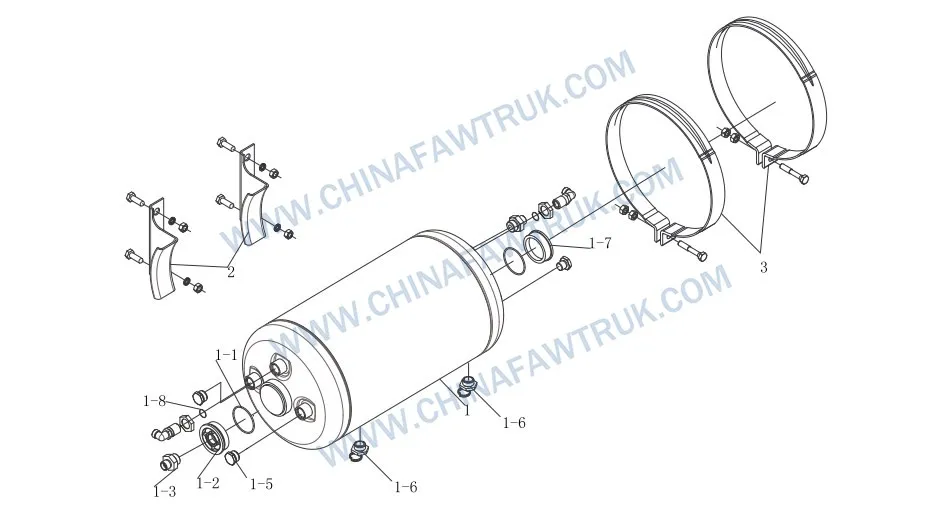

FAW Russian Auxiliary Air Tank

| No. |

Part Number |

Part Name |

Qty |

| 1 | 3513215-54A | Double Chamber Air Reservoir Assembly | 1 |

| 2 | 3513081-60A | Rear Axle Brake Air Reservoir Bracket | 2 |

| 3 | 3513086-362 | Hoop – For Air Reservoir Fastening | 2 |

| 1-1 | 3513028-73A | Sealing Ring (Φ54) | 2 |

| 1-2 | 3513026-73A | Reducing Joint / Adapter | 1 |

| 1-3 | 3509214-950 | Outlet Joint – Air Compressor | 2 |

| 1-4 | 3506204-55R | Elbow Connector | 2 |

| 1-5 | 3513420-50A | Plug Assembly (M22) | 3 |

| 1-6 | 3513100-240 | Drain Valve Assembly | 2 |

| 1-7 | 3513027-795 | Plug | 1 |

| 1-8 | 3513408-50A | Sealing Ring (Φ18.5) | 3 |

Reservoir Architecture: The Storage Imperative

Designing the FAW Russian Auxiliary Air Tank for the CA3250P66K24L1TE5Z chassis requires a fundamental reimagining of pneumatic storage capacity. In temperatures plummeting to -50°C, air density changes, and the reaction time of pneumatic valves can slow down. To combat this, the system relies heavily on the Double Chamber Air Reservoir Assembly (Part No. 3513215-54A). Unlike standard tanks, this Russian-spec unit features a compartmentalized internal structure that allows it to serve multiple independent braking circuits simultaneously. This “double chamber” design is a critical safety redundancy, ensuring that a leak in one circuit does not deplete the entire reserve capacity of the FAW Russian Auxiliary Air Tank.

The construction of the FAW Russian Auxiliary Air Tank utilizes heavy-gauge steel specifically treated to maintain ductility in extreme cold. Standard steel can become brittle and prone to shattering under impact at cryogenic temperatures—a distinct risk in mining environments where rock debris is common. The “54A” suffix in the assembly number indicates a specific surface treatment and internal coating designed to resist the corrosive effects of the alcohol-based antifreeze used in the Russian winter. This ensures that the FAW Russian Auxiliary Air Tank maintains its structural integrity for the vehicle’s lifespan.

Furthermore, the volume of the Double Chamber Air Reservoir Assembly is calculated to provide sufficient air volume for multiple emergency brake applications even if the compressor fails. This buffer capacity is the defining characteristic of the FAW Russian Auxiliary Air Tank system. It allows the driver to navigate long, icy descents where frequent modulation of the service brakes is required, without the fear of “running out of air.” The strategic placement of this auxiliary tank on the chassis ensures it remains protected while acting as a vital reservoir for the entire pneumatic network.

Mounting Logic: Brackets and Vibration Control

Securement is paramount for the FAW Russian Auxiliary Air Tank. A fully pressurized air tank is a potential hazard if it breaks loose on a rough haul road. The assembly utilizes the Rear Axle Brake Air Reservoir Bracket (Part No. 3513081-60A) as its primary anchor. These brackets are engineered to withstand the torsional twisting of the chassis frame. In the context of the FAW Russian Auxiliary Air Tank, these brackets act as a suspension system for the tank itself, isolating it from the high-frequency vibrations generated by the diesel engine and the road surface.

Holding the tank to these brackets is the Hoop – For Air Reservoir Fastening (Part No. 3513086-362). These hoops are not simple metal bands; they are lined with a vibration-dampening polymer that prevents metal-on-metal chafing. Without this liner, the vibration of the FAW Russian Auxiliary Air Tank would eventually wear through the tank wall, leading to a catastrophic rupture. The tensioning mechanism of the hoop ensures a constant clamping force, even as the metal expands and contracts with the extreme temperature fluctuations of the Russian climate.

The mounting geometry of the FAW Russian Auxiliary Air Tank also prioritizes ground clearance and impact protection. Positioned high within the chassis rails, the tank is shielded from rocks and ice chunks kicked up by the tires. However, this position makes the Rear Axle Brake Air Reservoir Bracket critical; if a bracket fractures, the tank could fall into the driveshaft or suspension components. Therefore, FAW specifies high-tensile steel for these brackets, ensuring that the FAW Russian Auxiliary Air Tank remains securely physically integrated with the truck regardless of the terrain.

Connectivity and Flow Dynamics

The utility of the FAW Russian Auxiliary Air Tank depends on its ability to rapidly effectively accept and discharge compressed air. This is managed by a series of specialized fittings, most notably the Reducing Joint / Adapter (Part No. 3513026-73A) and the Elbow Connector (Part No. 3506204-55R). These components are critical for routing the stiff, cold-resistant airlines into the tank ports without inducing stress on the piping. The “55R” designation on the elbow connector indicates a specific radius optimized for uninterrupted laminar airflow, ensuring that the FAW Russian Auxiliary Air Tank can dump its pressure into the brake chambers instantly when the pedal is stomped.

The Outlet Joint – Air Compressor (Part No. 3509214-950) serves as the primary interface for incoming air. In the FAW Russian Auxiliary Air Tank system, this joint must withstand the high heat of the compressed air coming directly from the drying unit. The material transition from the hot inlet to the cold tank body is managed by the Sealing Ring (Φ54) (Part No. 3513028-73A). This large seal is formulated to resist thermal set, maintaining a gas-tight seal even as the joint expands and contracts, preventing the “hissing” leaks that plague lesser systems in winter.

Furthermore, the FAW Russian Auxiliary Air Tank is designed with modularity in mind. The various ports allow for the connection of auxiliary accessories, such as air horns or seat suspension bladders, without compromising the primary braking reserve. The Plug Assembly (M22) (Part No. 3513420-50A) and the standard Plug (Part No. 3513027-795) are used to seal unused ports. These plugs are not permanent; they allow fleet mechanics to reconfigure the pneumatic layout if specific aftermarket equipment is added to the truck, adding versatility to the FAW Russian Auxiliary Air Tank architecture.

Moisture Management and Sealing Integrity

The greatest enemy of the FAW Russian Auxiliary Air Tank is liquid water. As hot compressed air cools within the tank, moisture condenses and pools at the bottom. If this water freezes, it reduces the tank’s volume and can block the outlet ports. To combat this, the assembly features the Drain Valve Assembly (Part No. 3513100-240). Located at the lowest point of the tank belly, this valve allows the operator to manually purge the condensate. In the FAW Russian Auxiliary Air Tank design, the valve mechanism is robust enough to be operated even when wearing thick winter gloves, facilitating essential daily maintenance.

Sealing integrity is maintained by the Sealing Ring (Φ18.5) (Part No. 3513408-50A). These smaller seals are used on the drain valves and test ports. While they appear insignificant, a failure of a single sealing ring in the FAW Russian Auxiliary Air Tank can lead to a slow leak that drains the system overnight, leaving the truck immobilized in the morning until pressure builds up. FAW utilizes a high-grade EPDM rubber compound for these seals, ensuring they remain flexible and do not crack when the temperature drops, preserving the air tightness of the FAW Russian Auxiliary Air Tank.

Finally, the FAW Russian Auxiliary Air Tank assembly represents a closed-loop safety system. The interaction between the Double Chamber Air Reservoir Assembly and its sealing components creates a reliable energy store. Regular inspection of the Drain Valve Assembly for ice blockage and checking the torque on the Hoop fasteners are mandatory maintenance procedures. By adhering to these protocols and using genuine parts, operators ensure that the FAW Russian Auxiliary Air Tank remains a reliable partner in the harsh Russian environment.

Conclusion: The Guarantee of Reserve Power

The FAW Russian Auxiliary Air Tank stands as a testament to engineering that refuses to compromise in the face of adversity. By integrating high-capacity storage, vibration-resistant mounting, and cold-weather sealing technology, FAW has created a system that delivers consistent, powerful pneumatic support in the world’s most unforgiving climates. Every component, from the Double Chamber Air Reservoir Assembly down to the smallest Sealing Ring, plays a pivotal role in ensuring that the CA3250P66K24L1TE5Z dump truck operates safely and efficiently, proving the indispensability of the FAW Russian Auxiliary Air Tank.

For fleet maintenance teams, adhering to the specifications in this assembly list is not optional—it is essential. Substituting genuine parts with standard alternatives invites failure. By maintaining the FAW Russian Auxiliary Air Tank with authentic components, operators ensure the longevity of their assets and the safety of their drivers, securing their operations against the unpredictable challenges of the Arctic frontier.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.