FAW Russian Balance Suspension Reaction-Rod: Mastering 7 Critical Links for Arctic Axle Alignment

The FAW Russian Balance Suspension Reaction-Rod assembly is the definitive torque management component for the rear bogie of the CA3250P66K24L1TE5Z dump truck. Often referred to as the torque rod or radius rod, this structural link is responsible for maintaining the precise angle of the drive axles during acceleration and braking. In the treacherous, icy conditions of the Siberian mining sector, the FAW Russian Balance Suspension Reaction-Rod prevents axle wind-up and wheel hop, ensuring that power is efficiently transferred to the ground. This guide explores the “55R” rubber joint technology, the high-tensile fastening architecture, and the crucial role of this assembly in maintaining vehicle stability.

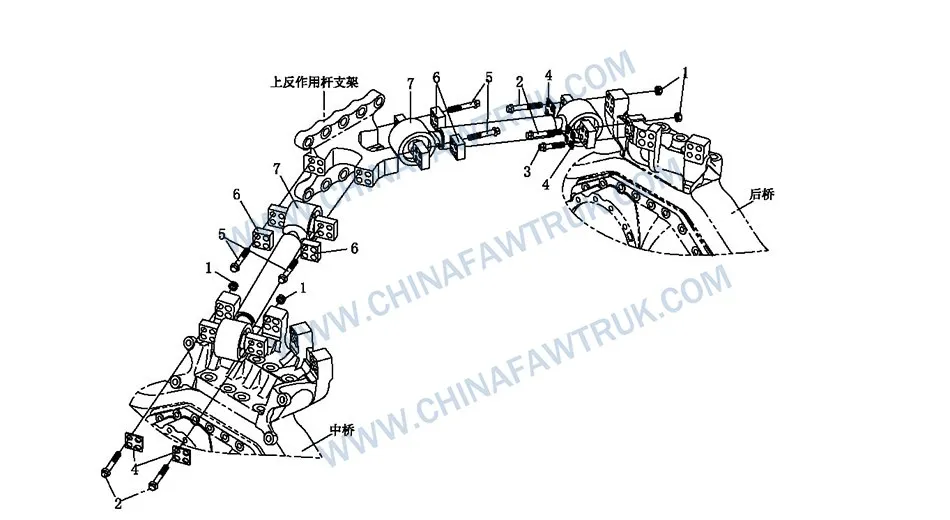

FAW Russian Balance Suspension Reaction-Rod

Core Linkage: The Reaction Rod Assembly

The backbone of this system is the Upper Reaction Rod with Rubber Joint Assembly (Part No. 2919005-55R-C00). This V-stay or linear rod connects the top of the axle housing to the chassis frame. Its primary function is to resist the rotational force (torque reaction) generated by the wheels. Without the FAW Russian Balance Suspension Reaction-Rod, the axle housing would rotate in the opposite direction of the wheels, twisting the leaf springs and potentially snapping the driveshaft u-joints. The “55R” designation indicates a specialized rubber compound used in the end bushings, formulated to remain flexible and crack-resistant at -50°C.

The “C00” suffix suggests a specific length and geometry tailored for the J6P chassis. The rod itself is forged from high-strength steel to withstand compressive and tensile loads exceeding 10 tons. In the FAW Russian Balance Suspension Reaction-Rod design, the rubber joints act as isolation points, absorbing high-frequency road vibrations and preventing them from being transmitted to the chassis. This protects the frame from fatigue cracking while improving driver comfort. The integrity of these rubber joints is the primary determinant of the rod’s service life.

Alignment is critical. The FAW Russian Balance Suspension Reaction-Rod sets the pinion angle of the drive axles. If the rod is bent or the bushings are worn, the pinion angle changes, leading to driveline vibration and rapid wear of the differential input bearings. Fleet mechanics must inspect the FAW Russian Balance Suspension Reaction-Rod for straightness and bushing condition regularly. A bent rod is a clear sign of severe overload or a chassis impact and requires immediate replacement.

The mounting points of the FAW Russian Balance Suspension Reaction-Rod experience immense stress. They must allow for a certain degree of articulation as the suspension cycles through its travel. The ball-and-socket style design of the rubber joint allows the axle to tilt and roll over uneven terrain without binding the suspension. This freedom of movement is essential for maintaining traction in the off-road environments where the CA3250P66K24L1TE5Z operates.

High-Shear Fastening Architecture

Securing the reaction rod to the chassis and axle requires a fastening system of uncompromising strength. The assembly utilizes three distinct variations of the Hexagon Head Flange Bolt: Part No. 2918518A64W, Part No. 2918518B64W, and Part No. 2918518-60W. The “64W” and “60W” suffixes indicate high-strength arctic steel grades, ensuring these bolts do not become brittle in extreme cold. The variation in part numbers likely reflects different shank lengths or thread pitches required for specific mounting locations on the FAW Russian Balance Suspension Reaction-Rod brackets.

These flange bolts are designed to distribute clamping force over a wide area, eliminating the need for separate washers. This is crucial for the FAW Russian Balance Suspension Reaction-Rod, as it prevents the bolt head from digging into the mounting bracket under heavy vibration. The bolts act as shear pins; they must resist the lateral forces trying to slice them in half during cornering. FAW’s engineering specifies a high torque value for these fasteners to generate sufficient friction grip between the mating surfaces.

To ensure the correct spacing and alignment of the rod ends, the assembly includes specialized washers: Washer – Reaction Rod Joint Assembly (Part No. 2919519A260) and Washer – Reaction Rod Assembly (Part No. 2919519B260). These precision-machined spacers are essential for centering the rubber joint within the bracket. If these washers are omitted or installed incorrectly, the FAW Russian Balance Suspension Reaction-Rod will be misaligned, causing rapid, uneven wear of the rubber bushing and potentially leading to metal-on-metal contact.

The sheer number of bolts—over 60 in total for the complete bogie assembly—highlights the redundancy and safety factors built into the system. Even if one bolt were to loosen, the FAW Russian Balance Suspension Reaction-Rod would remain secure, allowing the truck to return safely to the depot for repair. This robust design philosophy is what makes the FAW J6P a preferred choice for heavy-duty applications.

SPL Locking Technology

In the high-vibration environment of a dump truck, keeping fasteners tight is a constant battle. The FAW Russian Balance Suspension Reaction-Rod employs the SPL Hex Small Flange Anti-loose Nut (Part No. T32714TF2). The SPL (Self-Prevailing Lock) technology uses a deformed thread or metal interference design that locks the nut to the bolt thread. Unlike nylon lock nuts which can fail in extreme heat or cold, the all-metal SPL nut maintains its locking torque across the entire temperature range found in the Russian operational theater.

The flange face of the SPL Hex Small Flange Anti-loose Nut provides a stable bearing surface that spans the mounting hole. This is particularly important for the FAW Russian Balance Suspension Reaction-Rod, where the mounting holes are often slightly oversized to allow for alignment adjustment. The flange ensures that the clamping load is applied evenly to the bracket, preventing the nut from pulling through or loosening due to surface settling.

There are 28 of these specialized nuts used in the assembly. Fleet managers should consider them single-use items for critical repairs. While they can physically be reused, the locking feature degrades after the first installation. Given the critical role of the FAW Russian Balance Suspension Reaction-Rod in maintaining axle alignment, installing new SPL nuts during component replacement is a small cost for guaranteed safety.

Visual inspection of these nuts is straightforward. Mechanics should look for any gap between the nut flange and the bracket, or for rust trails indicating movement. Any looseness in the FAW Russian Balance Suspension Reaction-Rod fasteners will manifest as a distinct “clunk” when shifting from drive to reverse, alerting the driver to the need for immediate maintenance.

Maintenance for Longevity

The service life of the FAW Russian Balance Suspension Reaction-Rod is determined by the condition of the rubber joints. In the arctic, rubber hardens and can crack. Inspecting the Upper Reaction Rod with Rubber Joint Assembly (Part No. 2919005-55R-C00) for deep cracks or separation of the rubber from the metal sleeve is essential. If the rubber fails, the inner sleeve will hammer against the outer housing, destroying the rod end.

Re-torquing the mounting bolts (Part No. 2918518-60W) is a standard maintenance procedure. This should be done with the vehicle’s weight on the wheels to ensure the FAW Russian Balance Suspension Reaction-Rod sits in its neutral position. Tightening the bolts while the suspension is hanging (unloaded) can pre-stress the rubber bushings, causing them to tear prematurely when the truck is lowered.

When replacing the rod, it is crucial to use genuine FAW parts with the “55R” suffix. Aftermarket rods often use inferior rubber compounds that shatter in the cold. The FAW Russian Balance Suspension Reaction-Rod is a tuned component; its stiffness affects the entire suspension’s roll rate. Using the correct part ensures that the truck handles predictably and safely, protecting the driver and the payload.

By prioritizing the maintenance of the FAW Russian Balance Suspension Reaction-Rod, operators prevent cascading failures. A loose reaction rod puts excessive stress on the leaf springs and shock absorbers. Keeping this link tight and healthy is the most cost-effective way to ensure the long-term reliability of the rear bogie system.

Component Breakdown: Balance Suspension Upper Reaction Rod Logic

| No. |

Part Number |

Part Name |

Qty |

| 1 | T32714TF2 | SPL Hex Small Flange Anti-loose Nut | 28 |

| 2 | 2918518A64W | Hexagon Head Flange Bolt | 28 |

| 3 | 2918518B64W | Hexagon Head Flange Bolt | 4 |

| 4 | 2919519A260 | Washer – Reaction Rod Joint Assembly | 8 |

| 5 | 2918518-60W | Hexagon Head Flange Bolt | 32 |

| 6 | 2919519B260 | Washer – Reaction Rod Assembly | 8 |

| 7 | 2919005-55R-C00 | Upper Reaction Rod with Rubber Joint Assembly | 4 |

Conclusion: The Guarantee of Stability

The FAW Russian Balance Suspension Reaction-Rod is the guardian of the rear axle’s geometry. It converts the chaos of off-road driving into controlled, linear motion, protecting the drivetrain from destructive torque forces. By combining “55R” low-temperature rubber technology with a redundant, high-tensile fastening system, FAW has created a component that ensures the CA3250P66K24L1TE5Z remains stable and reliable, no matter how deep the snow or how heavy the load.

For fleet operators, understanding the critical nature of this rod is key to preventative maintenance. Regular checks of the bushings and fasteners can prevent expensive driveline repairs. Investing in genuine FAW parts ensures that the specific engineering requirements of the Russian market are met, keeping the truck on the road and earning revenue.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.