FAW Russian Fan Clutch: Mastering 6 Critical Components for Optimal Engine Thermal Control

The FAW Russian Fan Clutch logic assembly serves as the intelligent thermal modulator for the CA3250P66K24L1TE5Z dump truck. Situated between the water pump and the cooling fan, this viscous coupling system regulates airflow based on engine temperature demands. In the extreme volatility of the Russian climate, where engines must transition from -40°C cold starts to high-load mining hauls, this assembly ensures precise thermal management.

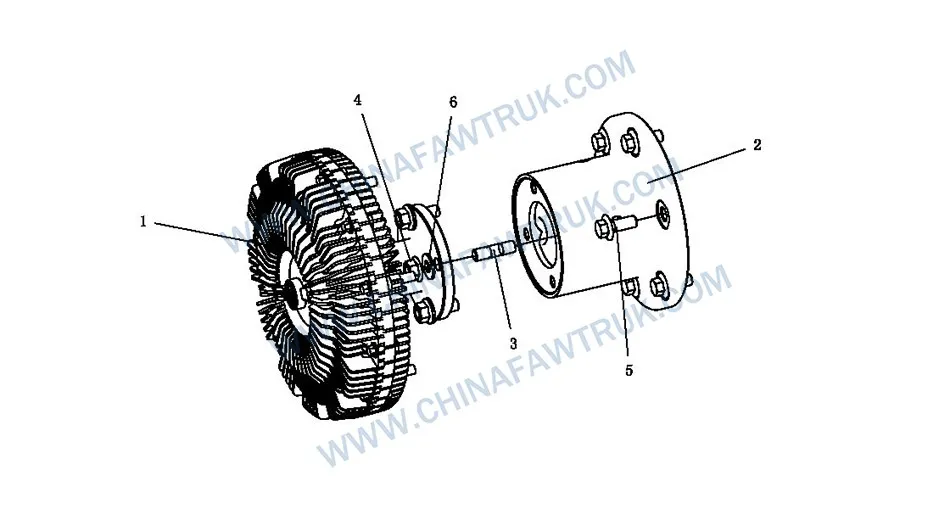

FAW Russian Fan Clutch

Viscous Dynamics: The Fan Clutch Assembly

The technological core of the system is the Fan Clutch Assembly (Part No. 1313010-73A). Within the FAW Russian Fan Clutch architecture, this component acts as a torque converter for the cooling fan. It utilizes a silicone-based viscous fluid and a bimetallic thermostatic sensor to engage or disengage the fan based on the air temperature passing through the radiator. In the Russian Arctic, this functionality is critical for engine efficiency. A fan that runs at full speed constantly would overcool the engine in winter, preventing it from reaching optimal operating temperature and wasting significant horsepower.

The FAW Russian Fan Clutch is calibrated specifically for cold climates. When the engine is cold, the viscous fluid is stored in an internal reservoir, allowing the fan to “freewheel” at a low RPM. This reduces parasitic drag and allows the engine to warm up quickly, which is vital for cabin heating and defrosting in Siberia. As the radiator heats up, the bimetallic spring on the front of the Fan Clutch Assembly expands, opening a valve that allows the silicone fluid to flow into the working chamber. This fluid creates shear resistance, locking the clutch and driving the fan at engine speed to provide maximum cooling.

The internal tolerances of the FAW Russian Fan Clutch are engineered to handle the viscosity changes of the fluid in extreme temperatures. Inferior clutches often seize in the cold or fail to engage when hot. The FAW specification ensures a smooth transition between disengaged and engaged states, preventing sudden shock loads on the belt drive system. This intelligent modulation is what separates the genuine FAW Russian Fan Clutch from a simple direct-drive hub, providing a balance of fuel economy and thermal protection that is essential for long-haul durability.

Connectivity Logic: The Transition Flange

Bridging the gap between the water pump pulley and the clutch unit is the Fan Clutch Transition Flange (Part No. 1313063-73A). This component is vital for maintaining the concentricity of the entire rotating assembly. The FAW Russian Fan Clutch operates at high rotational speeds, often exceeding 2,000 RPM. Any misalignment or runout in the transition flange would generate severe vibrations. These vibrations would not only destroy the water pump bearings but could also cause the plastic fan blades to shatter due to harmonic resonance.

The Fan Clutch Transition Flange is machined from high-strength steel or aluminum alloy to ensure perfect balance. Its mating surfaces are precision-ground to provide a flat, stable platform for the Fan Clutch Assembly. In the FAW Russian Fan Clutch system, this flange also acts as a thermal break, managing the heat transfer from the water pump shaft to the viscous clutch unit. This prevents the silicone fluid inside the clutch from overheating due to conductive heat from the engine block, ensuring that the clutch actuation is controlled solely by airflow temperature.

The robust design of the flange allows it to transmit the high torque required to drive the large-diameter fans used on dump trucks. During sudden engine acceleration, the inertia of the fan places a massive twisting force on this component. The FAW Russian Fan Clutch transition flange is engineered with sufficient material thickness to resist twisting or warping under these dynamic loads, maintaining the structural integrity of the cooling system stack.

Mounting Logic: Double End Bolts

The mounting strategy for the FAW Russian Fan Clutch employs specific Double End Bolt (Part No. CQ1201025), also known as studs. There are 4 of these studs utilized in the assembly. The choice of double-ended studs over standard bolts is a deliberate maintenance feature. When installing the heavy fan and clutch assembly in the tight confines of the engine bay, holding the unit in place while trying to thread a bolt is difficult and dangerous. Studs act as guide pins, allowing the technician to slide the Fan Clutch Transition Flange and clutch onto the water pump hub and let it hang there safely before applying nuts.

Securing these studs are the Hexagon Flange Nut (Part No. CQ39610). The use of flange nuts in the FAW Russian Fan Clutch assembly is critical for vibration resistance. The integrated flange acts as a washer, distributing the clamping load over a wider area on the flange face. This prevents the nut from embedding into the metal, which leads to torque loss. Furthermore, the serrated face often found on these flange nuts provides a mechanical lock against the backing-off forces generated by the fan’s rotation.

The metallurgy of the Double End Bolt and Hexagon Flange Nut is selected to withstand the high thermal cycling of the engine front end. As the components heat up and expand, the fasteners must retain their clamping tension without stretching or snapping. The FAW Russian Fan Clutch hardware is also treated with corrosion-resistant coatings to prevent the nuts from seizing onto the studs, ensuring that the assembly can be serviced easily even after years of exposure to road salt and moisture.

Peripheral Security: Bolts and Washers

Complementing the stud mounting are the Hexagon Flange Bolt Coarse Shank (Standard) (Part No. Q1841025). There are 6 of these bolts used in the logic assembly, likely securing the fan blades to the clutch face or the transition flange to the pulley. The “Coarse Shank” designation is significant for the FAW Russian Fan Clutch. Coarse threads provide a deeper engagement and are less prone to cross-threading during installation, which is a common issue when working with aluminum components. They also offer superior resistance to stripping under high-torque loads.

These bolts are paired with Washer (Part No. Q40110). While the flange bolts have their own broad heads, the additional washers are often used as spacers or to provide a pristine bearing surface on the mating component. In the FAW Russian Fan Clutch assembly, maintaining the correct stack height and alignment is crucial for belt alignment. Even a millimeter of deviation can cause the serpentine belt to squeal or jump off the pulley. The washers ensure that the bolts bottom out at the correct depth without damaging the blind holes in the casting.

The reliability of the FAW Russian Fan Clutch depends on the collective integrity of these fasteners. If a single bolt loosens, the dynamic balance of the fan is thrown off. This imbalance creates a destructive vibration loop that accelerates wear on the water pump bearings and can eventually lead to catastrophic fan separation. Therefore, adhering to the specific part numbers for these bolts and washers is not just a suggestion; it is a requirement for the safe operation of the vehicle.

Component Breakdown: 99. Fan Clutch Logic Assembly

| No. |

Part Number |

Part Name |

Qty |

| 1 |

1313010-73A |

Fan Clutch Assembly |

1 |

| 2 |

1313063-73A |

Fan Clutch Transition Flange |

1 |

| 3 |

CQ1201025 |

Double End Bolt |

4 |

| 4 |

CQ39610 |

Hexagon Flange Nut |

4 |

| 5 |

Q1841025 |

Hexagon Flange Bolt Coarse Shank (Standard) |

6 |

| 6 |

Q40110 |

Washer |

4 |

Conclusion: The Intelligent Link

The FAW Russian Fan Clutch assembly is the intelligent link between engine power and thermal regulation. By automating the engagement of the cooling fan, it optimizes the vehicle’s performance for the harsh realities of the Russian environment. It ensures quick warm-ups in the winter and powerful cooling in the summer, all while minimizing fuel consumption.

For fleet maintenance, the focus must be on using the correct replacement parts. A generic fan clutch may not have the correct temperature calibration or fluid viscosity for the Arctic, leading to engine damage. By sticking to the genuine FAW Russian Fan Clutch components, including the precision transition flange and high-grade fasteners, operators guarantee that their trucks remain thermally balanced and mechanically sound, mile after grueling mile.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.