Welcome to this critical technical guide on the FAW Spare Wheel Bracket assembly (Assembly 532). This is the complete, heavy-duty carrier system for the spare wheel on the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor. This assembly is a critical component for both safety and legal road-readiness.

The FAW Spare Wheel Bracket is a multi-part, chassis-mounted assembly. Its “logic” is to securely store a heavy (100kg+) truck wheel and tyre, ensuring it is safe from theft, protected from road debris, and does not vibrate loose. A loose spare wheel is a catastrophic road hazard.

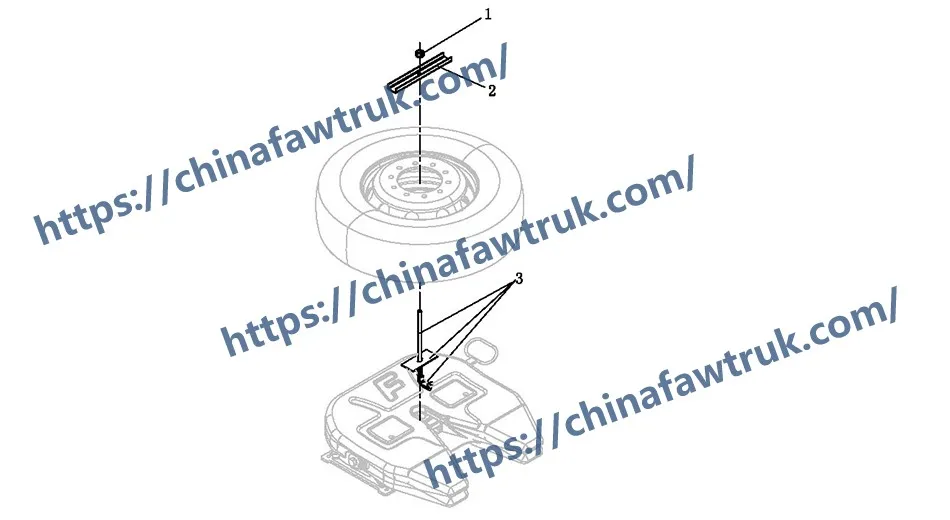

This in-depth guide is an essential resource for professional chassis technicians, body builders, and parts specialists. We will deconstruct the entire FAW Spare Wheel Bracket system into its 3 main serviceable component groups, including the ‘Bottom plate assy’ (3105015-91R), the ‘Upright hook assy’ (3105020-91R), and the critical ‘SPL lock nut’ (T32718).

The foundation of the FAW Spare Wheel Bracket is the ‘Spare tyre bracket bottom plate assy’ (3105015-91R). This is the main structural component that bears the entire weight of the spare wheel and tyre. This assembly is a heavy-duty fabrication of welded, high-strength steel.

This component bolts directly to the truck’s main C-channel frame rails. It is the “shelf” that the wheel rests on. This assembly (Mark 2) also includes the ‘Base plate-spare tyre bracket’ (3105011-91R), which is the main plate, and the two ‘Locating pin-spare tyre bracket’ (3105013-91R) units.

The “logic” of these ‘Locating pins’ is critical. They are hardened steel dowels that stick up from the base plate. The bolt holes of the spare wheel are slid *over* these pins. This is a key safety and ease-of-use feature of the FAW Spare Wheel Bracket. It allows the technician to “hang” the heavy wheel on these pins, supporting its weight *before* they have to install the fasteners. This prevents the wheel from sliding off and makes installation a one-person job. More importantly, these pins absorb all the “shear” force (the force of the wheel trying to slide off) during braking and cornering, taking the load off the fasteners. This is a critical part of the FAW Spare Wheel Bracket‘s design.

The second key “logic” of the FAW Spare Wheel Bracket is the ‘Spare tyre bracket upright hook assy’ (3105020-91R). This is the “clamping” mechanism that holds the wheel down. This assembly (Mark 3) is a multi-part welded fabrication that includes:

This component’s “logic” is simple but effective. The ‘Upright post’ is bolted to the truck’s frame. The spare wheel is hung on the ‘Locating pins’ of the base plate. Then, this ‘Upright hook assy’ is swung into place. The ‘Locating hook’ is a long, threaded rod (like a J-hook or T-hook) that passes through a bolt-hole on the wheel.

The ‘Locating plate’ acts as a large, flat washer, spreading the clamping force over a wide area of the wheel to prevent damage. This entire hook assembly is what provides the “clamping” force for the FAW Spare Wheel Bracket, pressing the wheel firmly against the vertical post and down onto the base plate, creating a rigid, vibration-proof mount. The FAW Spare Wheel Bracket relies on this hook for its security.

The final “logic” of the FAW Spare Wheel Bracket is its single, critical fastener: the ‘SPL hex small flange lock nut’ (T32718). This is the *only* part listed under Mark 1, highlighting its importance.

This is not a standard nut. It is an “SPL” (Stover Prevailing-torque Locknut) nut. Its “logic” is that the top threads are intentionally deformed (crimped) into a slight oval. When this nut is threaded onto the ‘Locating hook’ (3105016-91R), this deformed section creates an immense, “elastic” friction grip on the threads.

This is the safety-critical “logic” of the FAW Spare Wheel Bracket. A standard nut would, under the constant, high-frequency vibration of a truck’s chassis, slowly “walk” or “back off” the threads. This would eventually cause the ‘Upright hook assy’ to become loose, allowing the 100kg spare wheel to detach from the FAW Spare Wheel Bracket and fall onto the highway, a catastrophic and potentially fatal event.

This “SPL” lock nut is designed to be **immune** to vibration. It *cannot* back off on its own. This single, inexpensive part is the ultimate safety guarantee for the entire FAW Spare Wheel Bracket assembly. It is often a “single-use” or “limited-use” item; once it has been removed and re-installed multiple times, its locking properties diminish, and it must be replaced to ensure the continued safety of the FAW Spare Wheel Bracket.

The following table provides the complete, detailed breakdown of all 3 component groups (totaling 8 pieces) identified in the ‘Spare Wheel Bracket’ (532) diagram for the FAW CA4251P66K24T1A3E5 tractor.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | T32718 | SPL hex small flange lock nut | 1 |

| 2 | 3105011-91R | Base plate-spare tyre bracket | 1 |

| 3105013-91R | Locating pin-spare tyre bracket | 2 | |

| 3105015-91R | Spare tyre bracket bottom plate assy | 1 | |

| 3 | 3105012-91R | Fixed spare tyre bracket upright post | 1 |

| 3105014-91R | Spare tyre bracket locating plate | 1 | |

| 3105016-91R | Spare tyre bracket locating hook | 1 | |

| 3105020-91R | Spare tyre bracket upright hook assy | 1 |

The specifications for the FAW Spare Wheel Bracket are defined by its function as a heavy-duty, vibration-proof carrier. The FAW Spare Wheel Bracket is a critical safety and compliance assembly.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | FAW Spare Wheel Bracket |

| Main Base Assembly | 1x (Part No. 3105015-91R) |

| Main Hook Assembly | 1x (Part No. 3105020-91R) |

| Logic 1: Wheel Support | 2x ‘Locating pins’ (3105013-91R) |

| Logic 2: Clamping | 1x ‘Locating hook’ (3105016-91R) |

| Logic 3: Safety Fastener | 1x ‘SPL hex small flange lock nut’ (T32718) |

| Material (Typical) | High-Strength, Welded Steel |

| Primary Function | To securely and safely mount the heavy spare wheel and tyre to the vehicle’s chassis. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.