Welcome to this comprehensive technical deconstruction of the FAW Middle Housing Assembly (Part No. 1701035-A2V), also known as the “mid-case.” This is the central, structural skeleton of the main gearbox for the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor.

The FAW Middle Housing Assembly is arguably the most critical and complex casing in the entire transmission. Its function is to hold the main shaft, counter-shaft, and reverse idler shaft in perfect, parallel alignment, all while containing the transmission’s oil supply and supporting the shift-rail mechanism.

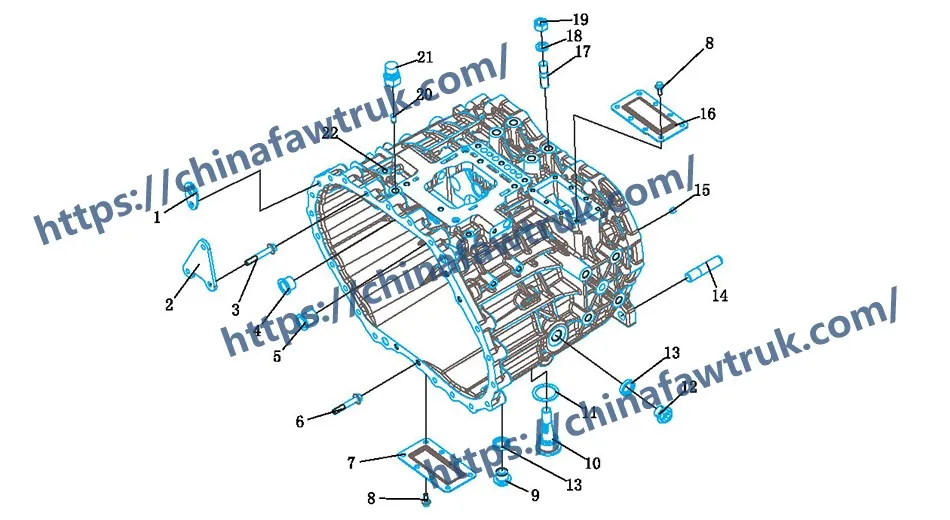

This in-depth guide is an essential resource for professional transmission technicians and parts specialists. We will analyze all 22 serviceable components of the FAW Middle Housing Assembly, including the main casing, its lubrication system (plugs, filters), the shift-fork bushings, and the critical reverse light switch.

The heart of this assembly is the ‘Mid-housing with steel wire sleeve set assy’ (1701035-A2V). This is the main body of the FAW Middle Housing Assembly. It is a massive, precision-machined casting, typically made of aluminum to save weight and effectively dissipate heat from the gear oil. This component is the “skeleton” that everything else bolts into.

Its most critical features are the internal, precision-bored “saddles” or “bores.” These are the holes that hold the main bearings for the input shaft, main shaft, and counter-shaft. These bores must be perfectly parallel to each other, as any misalignment would cause the gears to mesh improperly, leading to a catastrophic “whine” and rapid gear destruction.

The designation “with steel wire sleeve set assy” is a critical quality feature. It means that the high-stress threaded holes in the soft aluminum casting of the FAW Middle Housing Assembly have been reinforced with “Helicoils” (steel wire inserts). This is vital for the ‘Stud bolts’ (CQ1211640) and the many ‘Hex flange bolts’ (Q1841060S, Q1840820S) that hold the transmission together, preventing the threads from stripping during service and ensuring a high-torque, durable assembly. This is a core feature of a high-quality FAW Middle Housing Assembly.

The FAW Middle Housing Assembly is designed to hold several gallons of heavy-duty gear oil. This parts list details all the critical service points for this fluid.

**1. Oil Fill/Check:** The ‘Oil filler plug’ (1701041-A2K) is the “fill” port, located high on the side of the housing. The transmission is filled until oil begins to weep from this hole, which is how the correct oil level is set.

**2. Oil Drain:** The ‘Drain plug assy’ (1701765-A2K) is the “drain” port, located at the lowest point. This plug is typically magnetic, designed to trap any fine metal particles from normal gear wear. Inspecting this plug during an oil change is a critical diagnostic step for the health of the FAW Middle Housing Assembly.

**3. Sealing:** Both plugs are sealed by the ‘Gasket-plug, drain’ (1701042-A2K), of which there are two. These are “crush washers” and are single-use items that must be replaced to prevent leaks. The ‘Inner hex tapered screw plug’ (Q61901) is used to seal a manufacturing or diagnostic port on the FAW Middle Housing Assembly.

A critical, yet simple, component of the FAW Middle Housing Assembly‘s lubrication system is the ‘Filter screen assembly’ (1701050-A2K). This is the “pickup screen” for the transmission’s internal oil pump. It is located deep inside the housing, submerged in the oil sump.

Its function is to provide a “coarse” filter, blocking any large debris (e.g., chipped gear teeth, metal shavings, or gasket fragments) from being sucked into the high-pressure oil pump. A failure of this screen would allow debris to circulate, destroying the oil pump and subsequently starving the entire gearbox of lubrication.

The ‘Gasket-filter screen assembly’ (1701056-A2K) is the seal for this component. Its integrity is vital, as a failed gasket would allow the pump to suck in unfiltered oil from *around* the screen, defeating its purpose. This is a vital part of the FAW Middle Housing Assembly‘s longevity.

The FAW Middle Housing Assembly provides the foundation for the internal shift components (detailed in Assembly 153). This includes the ‘Bushing-reverse fork shaft’ (1701014-A9P) and the three ‘Bushing-shift fork shaft’ (1701013-A9P) units. These are the bronze “wear” bushings that are pressed into the aluminum housing. The hardened steel shift rails slide through these bushings, allowing for smooth, low-friction shifting.

The ‘Dowel pin-sub housing’ (1701052-A2V) units are used to perfectly align the FAW Middle Housing Assembly to the rear “sub-box” (auxiliary) housing.

A key electronic component mounted to this FAW Middle Housing Assembly is the ‘Reverse light switch assembly’ (3729100-54W-C00). This is a spring-loaded “plunger” switch. When the driver moves the shifter into the reverse gate, the reverse shift rail (supported by 1701014-A9P) pushes this plunger in, which completes an electrical circuit. This signal turns on the vehicle’s white reversing lights and the audible backup alarm, making it a critical safety component.

The following table provides the complete, detailed breakdown of all 22 components identified in the ‘Middle Housing Assembly’ diagram for the FAW CA4251P66K24T1A3E5 tractor. This FAW Middle Housing Assembly is the core of the main gearbox.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 1701711-A2K | Lifting eye | 1 |

| 2 | 1703166B41U | Bracket-support connecting rod | 1 |

| 3 | Q1841065S | Hex flange bolt, coarse rod (Standard Type) | 1 |

| 4 | 1701014-A9P | Bushing-reverse fork shaft | 1 |

| 5 | 1701013-A9P | Bushing-shift fork shaft | 3 |

| 6 | Q1841060S | Hex flange bolt, coarse rod (Standard Type) | 18 |

| 7 | 1701043-A9P | Cover – lower right idler | 1 |

| 8 | Q1840820S | Hex flange bolt, coarse rod (Standard Type) | 16 |

| 9 | 1701765-A2K | Drain plug assy | 1 |

| 10 | 1701050-A2K | Filter screen assembly | 1 |

| 11 | 1701056-A2K | Gasket-filter screen assembly | 1 |

| 12 | 1701041-A2K | Oil filler plug | 1 |

| 13 | 1701042-A2K | Gasket-plug, drain | 2 |

| 14 | 1701052-A2V | Dowel pin-sub housing | 2 |

| 15 | Q61901 | Inner hex tapered screw plug | 1 |

| 16 | 1701043-A2V | Cover – upper left idler | 1 |

| 17 | CQ1211640 | Stud bolt | 2 |

| 18 | Q40316 | Spring gasket | 2 |

| 19 | CQ34116 | Hex nut | 2 |

| 20 | 1702242-A9P | Post pin | 1 |

| 21 | 3729100-54W-C00 | Reverse light switch assembly | 1 |

| 22 | 1701035-A2V | Mid-housing with steel wire sleeve set assy | 1 |

The specifications for the FAW Middle Housing Assembly are defined by its function as the structural, precision-machined “mid-case” of the transmission. The entire FAW Middle Housing Assembly is a key structural component.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | FAW Middle Housing Assembly (Transmission) |

| Main Housing P/N | 1701035-A2V |

| Common Name | Transmission Mid-Case / Main Housing |

| Material (Typical) | Cast Aluminum with Steel Wire Thread Inserts |

| Key Feature | Houses main/counter shafts and shift rail bushings. |

| Integrated System 1 | Internal Oil Filtration (1701050-A2K) |

| Oil Fill (1701041-A2K) and Drain (1701765-A2K) Ports | |

| Electronic Sensor | Reverse Light Switch (3729100-54W-C00) |

| Primary Function | To house, protect, and lubricate all main gearbox components and ensure perfect shaft alignment. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.