Welcome to this critical safety breakdown of the Стеклоочиститель FAW сборка. This system is the primary active safety feature for the FAW Jiefang CA4251P66K24T1A3E5 6×4 дизельный полуприцеп тягач. Its function is non-negotiable: to provide the driver with a clear, unobstructed field of vision in adverse weather conditions, в том числе дождь, снег, and road spray.

The “Логическая сборка” для Стеклоочиститель FAW (P/N 5205010-A01 / 5205010АА01) is far more than just the wiper blades. Это полный, pre-assembled, and timed electro-mechanical system. Этот “логика” unit includes the wiper motor, a complex pantograph linkage, and the pivot shafts, all as a single part. This design ensures perfect, synchronized wiper geometry and high reliability.

This in-depth guide is essential for technicians and fleet managers. Мы разберем всю Стеклоочиститель FAW system into its three primary component types. Мы проанализируем “черный ящик” logic of the main ‘Wiper assy’ (the primary MSU), and the two sets of critical, anti-vibration fasteners (МГУ 2 & 3) that secure the system to the cab and the arms to the pivots.

To understand the Стеклоочиститель FAW сборка (5205010-А01), you must deconstruct it into its three core “логика” система, which are all combined into one MSU: the Motor, the Linkage, and the Arms/Blades.

1. The Motor & Экю “Логика” (The “Мозг”)

Сердце Стеклоочиститель FAW is its 24V DC electric motor. This is not a simple “вкл/выкл” мотор; it is an intelligent “логика” модуль.

Intermittent & Speed Logic: The motor housing contains a small Electronic Control Unit (Экю) or a set of complex relays. Когда водитель выбирает “intermittent,” this module’s “логика” takes over, using a timer to cycle the wipers every few seconds. Когда “Низкий” или “Высокий” speed is selected, this module sends power to different “кисти” (windings) in the motor to change its rotational speed.

The “Park” Логика: The most critical logic is the “park” функция. Ever wonder how wipers always stop at the bottom? Inside the motor’s gearbox is a cam and a “park switch.” When the driver turns the wipers “Выключенный,” the motor *does not* lose power. The park switch “логика” provides a *second* path for power, keeping the motor running. The motor continues to turn until a “notch” on the cam hits the switch, which physically cuts this second power path. Этот “notch” is precisely located to stop the motor *exactly* when the wiper arms are at their lowest “parked” позиция. A failure of this switch is why “bad” wipers stop in the middle of the windscreen.

2. The Pantograph Linkage “Логика” (The “Мышцы”)

The motor creates a rotary (spinning) движение. The wipers need a back-and-forth (oscillating) движение. The “логика” that converts this is the linkage.

Этот Стеклоочиститель FAW uses a “pantograph” связь. This is a complex system of pre-timed, pre-greased metal arms and pivot joints. The motor spins a short crank arm, which pushes and pulls this “pantograph” система. Этот “логика” is essential for a large, flat tractor windscreen. A simple “single-pivot” система (like on an old car) would leave a huge, un-wiped “triangle” at the top corners.

The pantograph “логика” ensures the two wiper arms move in a perfect, параллельный, or tandem “sweep,” clearing the maximum possible area. This entire linkage is the main component of the 5205010-A01 assembly, as it is sealed and timed at the factory.

3. The Arm & Blade “Логика” (The “Contact Patch”)

Though not in this specific parts list (they are separate MSUs), а “логика” принадлежащий Стеклоочиститель FAW is completed by the arms and blades. The wiper *arms* are spring-loaded. Этот “spring logic” имеет решающее значение; it applies several pounds of precise, downward pressure, forcing the rubber blade to conform to the curve of the glass. A weak spring is why old wipers “болтовня” или “skip” at high speed.

The wiper *blade* is the final MSU. Его “логика” is a flexible, “squeegee” edge. It is designed to “подбросить” its angle of attack on each direction of the wipe, ensuring a clean, streak-free removal of water.

Это основной компонент Стеклоочиститель FAW система. The ‘Wiper assy’ is the entire, pre-assembled, “черный ящик” unit containing both the motor and the linkage, as described above. The two part numbers likely refer to a “база” model and an “upgraded” (АА01) модель, or a slight design revision.

Сервисная логика: The “логика” of this part being a single MSU is serviceability. The internal gears of the motor are greased for life. The pantograph linkage is precisely timed and its joints are sealed. It is not designed to be repaired in the field.

A technician does not waste hours trying to diagnose a faulty “park switch” or a stripped plastic gear inside the motor. The “логика” is to treat the entire assembly as one part.

Режимы отказа:

Во всех этих случаях, the service “логика” is to replace the entire Стеклоочиститель FAW сборка (5205010-А01) as a single MSU.

The Стеклоочиститель FAW is a high-torque system that is constantly starting, stopping, and changing direction. This creates immense vibration. The fastener “логика” is designed *specifically* to combat this.

МГУ 2: «Комбинированный болт’ (CQ1460825F6) – Кол-во 6

The “логика” of these six bolts is to mount the entire ‘Wiper assy’ (МГУ 1) to the cab’s firewall/cowl structure. Это “three-point” mounting system, with two bolts per point, or a six-point system.

The “Комбинация” (комбинация) logic is critical. These bolts have a *captive, предварительно установленная стопорная шайба* (either a spring washer or serrated head). This lock washer provides constant tension, biting into the metal of the wiper bracket and the cab body. Этот “антивибрационный” logic is essential to prevent the motor and linkage from shaking loose, which would destroy the wiper geometry.

МГУ 3: ‘Hexagon head flange lock nut’ (Q032608) – Кол-во 2

The “логика” of these two nuts is to fasten the *wiper arms* onto the splined shafts of the pivots. A wiper arm *must* be mounted on a cone-shaped, splined (grooved) shaft so it can’t slip.

This nut provides the “сила зажима” that “bites” the soft metal of the arm onto the hardened steel spline. But its most important “логика” is that it is a **”контргайка фланца”**.

Both fastener types are critical MSUs. The lock nuts (Q032608) are **single-use**. They must be replaced every time the wiper arms are removed.

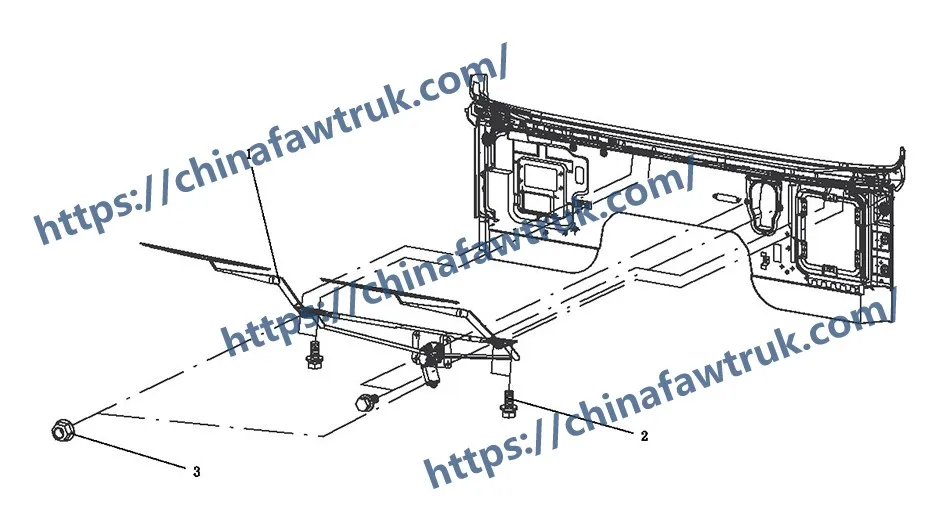

В следующей таблице представлена полная, подробная разбивка всех 3 типы компонентов, указанные в Стеклоочиститель FAW в сборе для трактора FAW CA4251P66K24T1A3E5.

| Отметка | Часть №. | Наименование | Количество |

|---|---|---|---|

| 1 | 5205010-А01 | Wiper assy | 1 |

| 5205010АА01 | Wiper assy | 1 | |

| 2 | CQ1460825F6 | Комбинированный болт | 6 |

| 3 | Q032608 | Hexagon head flange lock nut | 2 |

Технические характеристики Стеклоочиститель FAW определяются по своей функции как критически важное для безопасности, electro-mechanical system. All fasteners are high-tensile, anti-vibration components.

| Приложение для автомобиля | FAW Цзефан CA4251P66K24T1A3E5 6×4 Трактор |

| Группа компонентов | Стеклоочиститель FAW |

| Тип системы | Electro-mechanical Pantograph Wiper System |

| Системное напряжение | 24В Вашингтоне (Номинальный) |

| МГУ 1 (Основной) | ‘Wiper assy’ (5205010-А01 / 5205010АА01) |

| МГУ 1 Логика | Мотор, Экю (Speed/Park Logic), & Pantograph Linkage |

| МГУ 2 (Аппаратное обеспечение) | «Комбинированный болт’ (CQ1460825F6) – Кол-во 6 |

| МГУ 3 (Аппаратное обеспечение) | ‘Hexagon head flange lock nut’ (Q032608) – Кол-во 2 |

| Логика крепления | Антивибрационный (Комбинированный болт & Flange Lock Nut) |

| Удобство обслуживания | Высокий. Replace main ‘Wiper assy’ as one MSU. Lock nuts are single-use. |

Запчасти ФАВ, включая блок цилиндров в сборе, тщательно упакованы, чтобы обеспечить безопасную доставку. Каждый компонент закреплен защитными материалами для предотвращения повреждений при транспортировке.. Логистическая сеть гарантирует своевременную доставку по всему миру., поддержка эффективных операций по техническому обслуживанию. Ниже приведено изображение, иллюстрирующее стандартную упаковку запчастей для грузовиков FAW., демонстрация внимания к деталям в обращении и хранении.

Такой подход к упаковке сводит к минимуму риск коррозии или ударного повреждения., обеспечение доставки таких деталей, как блок цилиндров FAW в сборе, в идеальном состоянии.. Клиенты могут положиться на логистику FAW для обеспечения стабильного качества и надежности..