Welcome to this critical safety breakdown of the FAW Scrubber, or windscreen washer, assemblée (Réf.: 5207010-D03-C00). This system is a primary active-safety feature on the FAW Jiefang CA4251P66K24T1A3E5 6×4 tracteur semi-remorque diesel. C'est “logique” is to work in perfect synchronization with the ‘FAW Windscreen Wiper’ (Assemblée 629) to provide the driver with a clear, unobstructed field of vision. This is essential for safe operation in all weather, especially when dealing with road salt, boue, and insect impacts.

Le FAW Scrubber is not just a bottle; c'est un “assemblage logique” that comprises several key sub-systems: a fluid reservoir, a high-pressure electric pump, fluid lines (tuyaux), and spray nozzles. Le “logique” is to store and deliver cleaning fluid on demand, pressurized and atomized, to the ‘Windscreen’ (Assemblée 630). This system is designed for high-vibration, all-weather environments, from sub-zero winters to high-heat summer operation.

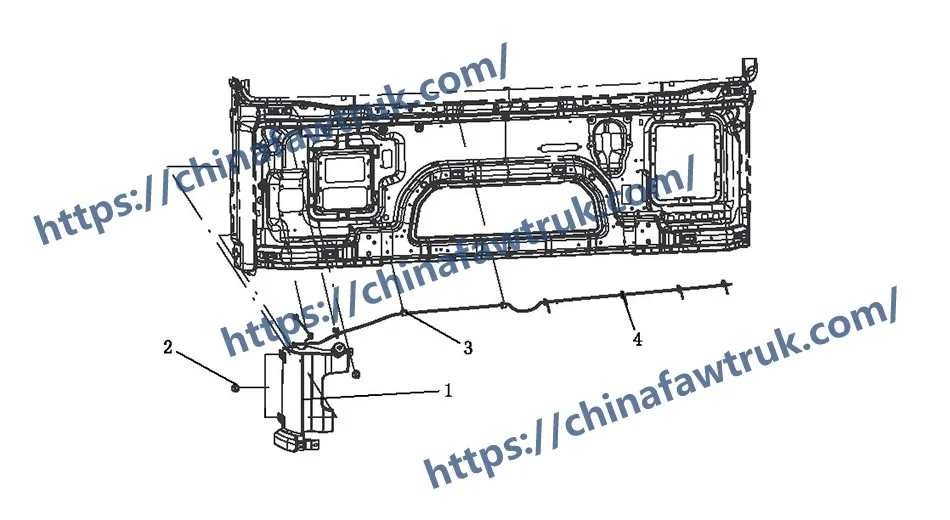

This in-depth guide is an essential resource for technicians, gestionnaires de flotte, et spécialistes des pièces détachées. Nous déconstruirons l'ensemble FAW Scrubber assembly as detailed in the parts diagram. We will analyze the main ‘Washer assy’ (MSU 2) as the primary “boîte noire” composant, and just as importantly, the critical “installation logic” of the three other MSUs: the anti-vibration ‘lock nuts’ (MSU 3), and the ‘straps’ (MSU 1 & 4) that secure the system’s vital arteries.

Ce composant est le “plus long” and most complex part of the FAW Scrubber système. The ‘Washer assy’ (5207010-D03-C00) is the primary MSU, un “boîte noire” unit that is replaced as a single part. C'est “logique” is to combine three critical functions into one pre-sealed, factory-tested assembly.

1. The Reservoir “Logique” (Storage)

The main body of the ‘Washer assy’ is the fluid reservoir (le “bottle”). This is not a simple container. C'est “logique” is based on material science and design.

Matériel: It is blow-molded from High-Density Polyethylene (HDPE). This material is chosen for its specific “logique”:

Conception: The reservoir is molded into a complex, vehicle-specific shape to maximize fluid capacity (often 3-5 litres) while fitting perfectly into the unused, irregular space in the engine bay. It includes a long, ergonomic filler neck and a “breather” capuchon.

2. The Electric Pump “Logique” (Pouvoir)

Integrated into the base of the reservoir is the electric washer pump. C'est le “muscle” de la FAW Scrubber. It is a 24V DC motor that drives a small centrifugal impeller.

C'est “logique” is to provide high pressure (psi) to atomize the fluid at the nozzles. It is mounted at the *bottom* of the tank, un “gravity-fed” logic that ensures the pump is always primed and can use every last drop of fluid. The pump is activated by the ‘Combination Switch’ on the steering column, lequel (via a relay) sends power to this motor.

3. The Fluid Level Sensor “Logique” (Warning)

Also integrated into the ‘Washer assy’ is a low-fluid-level sensor. This is a critical HMI “logique” fonction. It is typically a “reed switch” avec un “float.” When the fluid level drops, a magnetic float sinks, closing an electrical circuit.

This signal is sent to the ‘Combination Instrumentation’ (Assemblée 589), illuminating the amber “Low Washer Fluid” warning light. This gives the driver advanced notice to refill, Assurer le FAW Scrubber is always ready.

Because all three of these components are integrated, any failure (a cracked tank, a dead pump, or a faulty sensor) requires the replacement of the single ‘Washer assy’ MSU.

While the ‘Washer assy’ is the heart, le FAW Scrubber system relies on two other (implicit) sets of components to function: hoses and nozzles.

Hose “Logique”: The system uses flexible EPDM rubber or nylon tubing to connect the pump’s output port to the nozzles. Le “logique” of this tubing is durability. It must be routed safely through the engine bay, secured by the ‘Harness clips’ (MSU 1) and ‘Plastic straps’ (MSU 4) to prevent it from kinking, chafing, or melting on a hot exhaust manifold. A hole in this hose is a common failure, resulting in a weak or non-existent spray.

Nozzle “Logique”: The fluid is expelled through two or three “nozzles” (ou “jets”) located on the cowl panel or on the wiper arms themselves. Le “logique” of a modern nozzle is “atomization.” They are not simple “squirters.” They are engineered to break the fluid into a fine, wide “ventilateur” spray that covers the maximum glass area, allowing the ‘Windscreen Wiper’ (629) to clear the glass in a single pass.

The remaining 3 MSUs in the FAW Scrubber parts list form the complete installation and routing kit. Leur “logique” is to ensure the system is mounted securely and its “arteries” (hoses and wires) are protected.

MSU 3: ‘Hexagon head flange lock nut’ (Q032606) – Quantité 3

C'est le “anti-vibration” mounting logic. The ‘Washer assy’ (MSU 2) has three molded-in mounting points that slide over fixed studs on the cab’s inner fender or firewall. These three nuts are what hold the entire 10-pound (when full) assembly in place.

They are not standard nuts. They are “flange lock nuts.”

MSU 1 & 4: ‘Harness clip’ (3724012-A01) & ‘Plastic strap’ (T67414646) – Quantité 7 total

C'est le “routing logic” pour le FAW Scrubber système. This kit of 7 clips and straps is used to secure the pump’s electrical wire and the fluid hose. Leur “logique” is to prevent chafing and heat damage. A technician uses these MSUs to fasten the hose/wire securely to the chassis, far away from the hot engine block, the exhaust manifold, and any moving parts (like the steering shaft or fan belts). A missing clip can lead to a melted hose or a shorted wire, disabling the entire system.

Le tableau suivant fournit l'intégralité, ventilation détaillée de tous 4 types de composants identifiés dans le FAW Scrubber (Machine à laver) ensemble pour tracteur FAW CA4251P66K24T1A3E5.

| Marque | Partie no. | Nom de la pièce | Quantité |

|---|---|---|---|

| 1 | 3724012-A01 | Clip de faisceau de type à attache de câble II | 3 |

| 2 | 5207010-D03-C00 | Washer assy | 1 |

| 3 | Q032606 | Hexagon head flange lock nut | 3 |

| 4 | T67414646 | Plastic retaining strap | 4 |

Les spécifications pour le FAW Scrubber se définissent par sa fonction de système intégré, electro-mechanical fluid delivery system for the windscreen.

| Demande de véhicule | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tracteur |

| Groupe de composants | FAW Scrubber (Machine à laver) |

| Type de système | Windscreen Washer System (Électrique) |

| Tension du système | 24À DC (Nominal) |

| MSU 1 (Principal) | ‘Washer assy’ (5207010-D03-C00) – Quantité 1 |

| MSU 1 Sub-Parts | HDPE Reservoir, 24V Electric Pump, Fluid Level Sensor |

| MSU 2 (Matériel) | ‘Hexagon head flange lock nut’ (Q032606) – Quantité 3 |

| MSU 3 & 4 (Routing) | ‘Harness clip’ (3724012-A01) / ‘Plastic strap’ (T67414646) – Quantité 7 total |

| Logique de fixation | Anti-vibrations (Flange Lock Nut), Secure Routing (Clips/Straps) |

| Facilité d'entretien | Main ‘Washer assy’ is a single, sealed MSU. Lock nuts are single-use. |

Pièces FAW, y compris l'ensemble bloc-cylindres, sont emballés avec soin pour garantir une livraison en toute sécurité. Chaque composant est sécurisé dans des matériaux de protection pour éviter tout dommage pendant le transport. Le réseau logistique garantit des expéditions ponctuelles dans le monde entier, soutenir des opérations de maintenance efficaces. Vous trouverez ci-dessous une image illustrant l'emballage standard des pièces de camion FAW., mettant en valeur l’attention portée aux détails dans la manipulation et le stockage.

Cette approche d'emballage minimise le risque de corrosion ou de dommages causés par les chocs., s'assurer que les pièces comme l'ensemble bloc-cylindres FAW arrivent en parfait état. Les clients peuvent compter sur la logistique de FAW pour une qualité et une fiabilité constantes.