Welcome to this critical safety breakdown of the Depurador FAW, o lavaparabrisas, asamblea (P/N: 5207010-D03-C00). This system is a primary active-safety feature on the FAW Jiefang CA4251P66K24T1A3E5 6×4 tractor semirremolque diésel. Es “lógica” is to work in perfect synchronization with the ‘FAW Windscreen Wiper’ (Asamblea 629) to provide the driver with a clear, unobstructed field of vision. This is essential for safe operation in all weather, especially when dealing with road salt, lodo, and insect impacts.

El Depurador FAW is not just a bottle; es un “logic assembly” that comprises several key sub-systems: a fluid reservoir, a high-pressure electric pump, fluid lines (mangueras), and spray nozzles. El “lógica” is to store and deliver cleaning fluid on demand, pressurized and atomized, to the ‘Windscreen’ (Asamblea 630). This system is designed for high-vibration, all-weather environments, from sub-zero winters to high-heat summer operation.

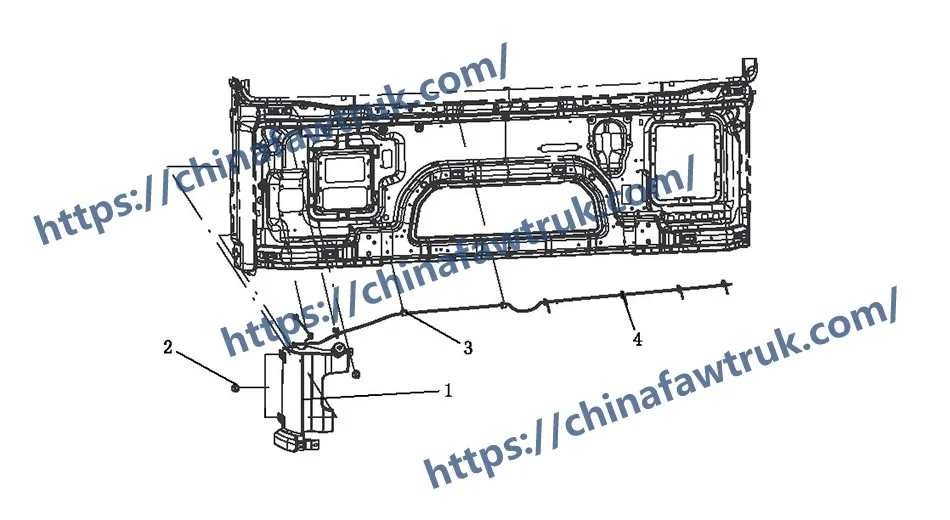

This in-depth guide is an essential resource for technicians, administradores de flotas, y especialistas en repuestos. Deconstruiremos todo Depurador FAW assembly as detailed in the parts diagram. We will analyze the main ‘Washer assy’ (Universidad Estatal de Michigan 2) as the primary “black box” componente, and just as importantly, el critico “installation logic” of the three other MSUs: the anti-vibration ‘lock nuts’ (Universidad Estatal de Michigan 3), and the ‘straps’ (MSU 1 & 4) that secure the system’s vital arteries.

Este componente es el “más extenso” y la parte más compleja del Depurador FAW sistema. The ‘Washer assy’ (5207010-D03-C00) is the primary MSU, a “black box” unit that is replaced as a single part. Es “lógica” is to combine three critical functions into one pre-sealed, factory-tested assembly.

1. The Reservoir “Lógica” (Almacenamiento)

The main body of the ‘Washer assy’ is the fluid reservoir (el “bottle”). This is not a simple container. Es “lógica” is based on material science and design.

Material: It is blow-molded from High-Density Polyethylene (HDPE). This material is chosen for its specific “lógica”:

Diseño: The reservoir is molded into a complex, vehicle-specific shape to maximize fluid capacity (a menudo 3-5 litros) while fitting perfectly into the unused, irregular space in the engine bay. It includes a long, ergonomic filler neck and a “breather” tapa.

2. The Electric Pump “Lógica” (Fuerza)

Integrated into the base of the reservoir is the electric washer pump. Este es el “músculo” del Depurador FAW. It is a 24V DC motor that drives a small centrifugal impeller.

Es “lógica” is to provide high pressure (PSI) to atomize the fluid at the nozzles. It is mounted at the *bottom* of the tank, a “gravity-fed” logic that ensures the pump is always primed and can use every last drop of fluid. The pump is activated by the ‘Combination Switch’ on the steering column, cual (via a relay) sends power to this motor.

3. The Fluid Level Sensor “Lógica” (Warning)

Also integrated into the ‘Washer assy’ is a low-fluid-level sensor. This is a critical HMI “lógica” función. It is typically a “reed switch” con un “flotar.” When the fluid level drops, a magnetic float sinks, closing an electrical circuit.

This signal is sent to the ‘Combination Instrumentation’ (Asamblea 589), illuminating the amber “Low Washer Fluid” warning light. This gives the driver advanced notice to refill, asegurando el Depurador FAW is always ready.

Because all three of these components are integrated, any failure (a cracked tank, a dead pump, or a faulty sensor) requires the replacement of the single ‘Washer assy’ Universidad Estatal de Michigan.

While the ‘Washer assy’ is the heart, el Depurador FAW system relies on two other (implicit) sets of components to function: hoses and nozzles.

Manguera “Lógica”: The system uses flexible EPDM rubber or nylon tubing to connect the pump’s output port to the nozzles. El “lógica” of this tubing is durability. It must be routed safely through the engine bay, secured by the ‘Harness clips’ (Universidad Estatal de Michigan 1) and ‘Plastic straps’ (Universidad Estatal de Michigan 4) to prevent it from kinking, chafing, or melting on a hot exhaust manifold. A hole in this hose is a common failure, resulting in a weak or non-existent spray.

Boquilla “Lógica”: The fluid is expelled through two or three “nozzles” (o “jets”) located on the cowl panel or on the wiper arms themselves. El “lógica” of a modern nozzle is “atomization.” They are not simple “squirters.” They are engineered to break the fluid into a fine, wide “admirador” spray that covers the maximum glass area, allowing the ‘Windscreen Wiper’ (629) to clear the glass in a single pass.

The remaining 3 MSUs in the Depurador FAW parts list form the complete installation and routing kit. Su “lógica” is to ensure the system is mounted securely and its “arteries” (hoses and wires) are protected.

Universidad Estatal de Michigan 3: ‘Hexagon head flange lock nut’ (Q032606) – Cantidad 3

Este es el “antivibración” mounting logic. The ‘Washer assy’ (Universidad Estatal de Michigan 2) has three molded-in mounting points that slide over fixed studs on the cab’s inner fender or firewall. These three nuts are what hold the entire 10-pound (when full) assembly in place.

They are not standard nuts. Ellos son “flange lock nuts.”

MSU 1 & 4: ‘Harness clip’ (3724012-A01) & ‘Plastic strap’ (T67414646) – Cantidad 7 total

Este es el “routing logic” para el Depurador FAW sistema. This kit of 7 clips and straps is used to secure the pump’s electrical wire and the fluid hose. Su “lógica” is to prevent chafing and heat damage. A technician uses these MSUs to fasten the hose/wire securely to the chassis, far away from the hot engine block, the exhaust manifold, and any moving parts (like the steering shaft or fan belts). A missing clip can lead to a melted hose or a shorted wire, disabling the entire system.

La siguiente tabla proporciona la información completa, desglose detallado de todos 4 tipos de componentes identificados en el Depurador FAW (Lavadora) Conjunto para el tractor FAW CA4251P66K24T1A3E5..

| Marca | Número de pieza. | Nombre de la pieza | Cantidad |

|---|---|---|---|

| 1 | 3724012-A01 | Cable tie type harness clip II | 3 |

| 2 | 5207010-D03-C00 | Washer assy | 1 |

| 3 | Q032606 | Hexagon head flange lock nut | 3 |

| 4 | T67414646 | Plastic retaining strap | 4 |

Las especificaciones para el Depurador FAW are defined by its function as an integrated, electro-mechanical fluid delivery system for the windscreen.

| Solicitud de vehículo | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Grupo de componentes | Depurador FAW (Lavadora) |

| Tipo de sistema | Windscreen Washer System (Eléctrico) |

| Voltaje del sistema | 24En DC (Nominal) |

| Universidad Estatal de Michigan 1 (Principal) | ‘Washer assy’ (5207010-D03-C00) – Cantidad 1 |

| Universidad Estatal de Michigan 1 Sub-Parts | HDPE Reservoir, 24V Electric Pump, Fluid Level Sensor |

| Universidad Estatal de Michigan 2 (Hardware) | ‘Hexagon head flange lock nut’ (Q032606) – Cantidad 3 |

| MSU 3 & 4 (Routing) | ‘Harness clip’ (3724012-A01) / ‘Plastic strap’ (T67414646) – Cantidad 7 total |

| Lógica de sujetadores | Antivibración (Flange Lock Nut), Secure Routing (Clips/Straps) |

| Utilidad | Main ‘Washer assy’ is a single, sealed MSU. Lock nuts are single-use. |

piezas FAW, incluido el conjunto del bloque de cilindros, Se empaquetan con cuidado para garantizar una entrega segura.. Cada componente está asegurado con materiales protectores para evitar daños durante el transporte.. La red logística garantiza envíos puntuales en todo el mundo., apoyando operaciones de mantenimiento eficientes. A continuación se muestra una imagen que ilustra el embalaje estándar de las piezas de camiones FAW., mostrando la atención al detalle en el manejo y almacenamiento.

Este enfoque de embalaje minimiza el riesgo de corrosión o daños por impacto., asegurando que piezas como el conjunto de bloque de cilindros FAW lleguen en perfectas condiciones. Los clientes pueden confiar en la logística de FAW para obtener calidad y confiabilidad constantes.