Welcome to this critical safety breakdown of the ФАВ Скруббер, or windscreen washer, сборка (Артикул: 5207010-D03-C00). This system is a primary active-safety feature on the FAW Jiefang CA4251P66K24T1A3E5 6×4 дизельный полуприцеп тягач. Его “логика” is to work in perfect synchronization with the ‘FAW Windscreen Wiper’ (Сборка 629) to provide the driver with a clear, unobstructed field of vision. This is essential for safe operation in all weather, especially when dealing with road salt, грязь, and insect impacts.

The ФАВ Скруббер is not just a bottle; это “логическая сборка” that comprises several key sub-systems: a fluid reservoir, a high-pressure electric pump, fluid lines (шланги), and spray nozzles. The “логика” is to store and deliver cleaning fluid on demand, pressurized and atomized, to the ‘Windscreen’ (Сборка 630). This system is designed for high-vibration, all-weather environments, from sub-zero winters to high-heat summer operation.

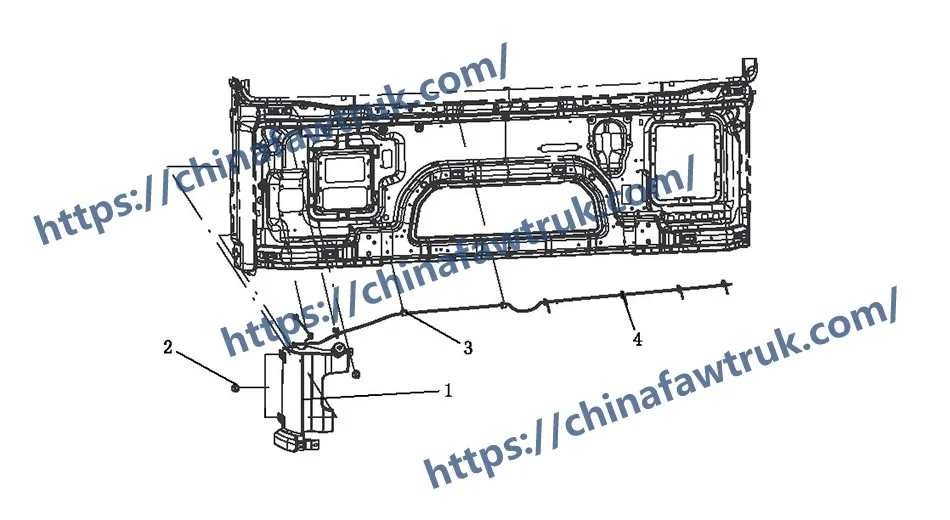

This in-depth guide is an essential resource for technicians, менеджеры автопарка, и специалисты по запчастям. Мы разберем всю ФАВ Скруббер assembly as detailed in the parts diagram. We will analyze the main ‘Washer assy’ (МГУ 2) as the primary “черный ящик” компонент, and just as importantly, критический “installation logic” of the three other MSUs: the anti-vibration ‘lock nuts’ (МГУ 3), and the ‘straps’ (МГУ 1 & 4) that secure the system’s vital arteries.

Этот компонент является “дольше” и самая сложная часть ФАВ Скруббер система. The ‘Washer assy’ (5207010-D03-C00) is the primary MSU, а “черный ящик” unit that is replaced as a single part. Его “логика” is to combine three critical functions into one pre-sealed, factory-tested assembly.

1. Водохранилище “Логика” (Хранилище)

The main body of the ‘Washer assy’ is the fluid reservoir (а “bottle”). This is not a simple container. Его “логика” is based on material science and design.

Материал: It is blow-molded from High-Density Polyethylene (ПНД). This material is chosen for its specific “логика”:

Дизайн: The reservoir is molded into a complex, vehicle-specific shape to maximize fluid capacity (often 3-5 литры) while fitting perfectly into the unused, irregular space in the engine bay. It includes a long, ergonomic filler neck and a “breather” cap.

2. The Electric Pump “Логика” (Власть)

Integrated into the base of the reservoir is the electric washer pump. Это “мышца” принадлежащий ФАВ Скруббер. It is a 24V DC motor that drives a small centrifugal impeller.

Его “логика” is to provide high pressure (пси) to atomize the fluid at the nozzles. It is mounted at the *bottom* of the tank, а “gravity-fed” logic that ensures the pump is always primed and can use every last drop of fluid. The pump is activated by the ‘Combination Switch’ on the steering column, который (через реле) sends power to this motor.

3. The Fluid Level Sensor “Логика” (Warning)

Also integrated into the ‘Washer assy’ is a low-fluid-level sensor. This is a critical HMI “логика” функция. It is typically a “reed switch” с а “float.” When the fluid level drops, a magnetic float sinks, closing an electrical circuit.

This signal is sent to the ‘Combination Instrumentation’ (Сборка 589), illuminating the amber “Low Washer Fluid” warning light. This gives the driver advanced notice to refill, обеспечение ФАВ Скруббер is always ready.

Because all three of these components are integrated, any failure (a cracked tank, a dead pump, or a faulty sensor) requires the replacement of the single ‘Washer assy’ МГУ.

While the ‘Washer assy’ is the heart, а ФАВ Скруббер system relies on two other (implicit) sets of components to function: hoses and nozzles.

Шланг “Логика”: The system uses flexible EPDM rubber or nylon tubing to connect the pump’s output port to the nozzles. The “логика” of this tubing is durability. It must be routed safely through the engine bay, secured by the ‘Harness clips’ (МГУ 1) and ‘Plastic straps’ (МГУ 4) to prevent it from kinking, раздражение, or melting on a hot exhaust manifold. A hole in this hose is a common failure, resulting in a weak or non-existent spray.

Nozzle “Логика”: The fluid is expelled through two or three “nozzles” (или “jets”) located on the cowl panel or on the wiper arms themselves. The “логика” of a modern nozzle is “atomization.” They are not simple “squirters.” They are engineered to break the fluid into a fine, wide “вентилятор” spray that covers the maximum glass area, allowing the ‘Windscreen Wiper’ (629) to clear the glass in a single pass.

The remaining 3 MSUs in the ФАВ Скруббер parts list form the complete installation and routing kit. Их “логика” is to ensure the system is mounted securely and its “arteries” (hoses and wires) are protected.

МГУ 3: ‘Hexagon head flange lock nut’ (Q032606) – Кол-во 3

Это “антивибрационный” mounting logic. The ‘Washer assy’ (МГУ 2) has three molded-in mounting points that slide over fixed studs on the cab’s inner fender or firewall. These three nuts are what hold the entire 10-pound (when full) assembly in place.

They are not standard nuts. Они есть “flange lock nuts.”

МГУ 1 & 4: ‘Harness clip’ (3724012-А01) & «Пластиковый ремешок’ (Т67414646) – Кол-во 7 общий

Это “routing logic” для ФАВ Скруббер система. This kit of 7 clips and straps is used to secure the pump’s electrical wire and the fluid hose. Их “логика” is to prevent chafing and heat damage. A technician uses these MSUs to fasten the hose/wire securely to the chassis, far away from the hot engine block, the exhaust manifold, and any moving parts (like the steering shaft or fan belts). A missing clip can lead to a melted hose or a shorted wire, disabling the entire system.

В следующей таблице представлена полная, подробная разбивка всех 4 типы компонентов, указанные в ФАВ Скруббер (Шайба) в сборе для трактора FAW CA4251P66K24T1A3E5.

| Отметка | Часть №. | Наименование | Количество |

|---|---|---|---|

| 1 | 3724012-А01 | Клип женика типа кабеля II | 3 |

| 2 | 5207010-D03-C00 | Washer assy | 1 |

| 3 | Q032606 | Hexagon head flange lock nut | 3 |

| 4 | Т67414646 | Plastic retaining strap | 4 |

Технические характеристики ФАВ Скруббер are defined by its function as an integrated, electro-mechanical fluid delivery system for the windscreen.

| Приложение для автомобиля | FAW Цзефан CA4251P66K24T1A3E5 6×4 Трактор |

| Группа компонентов | ФАВ Скруббер (Шайба) |

| Тип системы | Windscreen Washer System (Электрический) |

| Системное напряжение | 24В Вашингтоне (Номинальный) |

| МГУ 1 (Основной) | ‘Washer assy’ (5207010-D03-C00) – Кол-во 1 |

| МГУ 1 Sub-Parts | HDPE Reservoir, 24V Electric Pump, Fluid Level Sensor |

| МГУ 2 (Аппаратное обеспечение) | ‘Hexagon head flange lock nut’ (Q032606) – Кол-во 3 |

| МГУ 3 & 4 (Маршрутизация) | ‘Harness clip’ (3724012-А01) / «Пластиковый ремешок’ (Т67414646) – Кол-во 7 общий |

| Логика крепления | Антивибрационный (Flange Lock Nut), Secure Routing (Clips/Straps) |

| Удобство обслуживания | Main ‘Washer assy’ это одиночный, sealed MSU. Lock nuts are single-use. |

Запчасти ФАВ, включая блок цилиндров в сборе, тщательно упакованы, чтобы обеспечить безопасную доставку. Каждый компонент закреплен защитными материалами для предотвращения повреждений при транспортировке.. Логистическая сеть гарантирует своевременную доставку по всему миру., поддержка эффективных операций по техническому обслуживанию. Ниже приведено изображение, иллюстрирующее стандартную упаковку запчастей для грузовиков FAW., демонстрация внимания к деталям в обращении и хранении.

Такой подход к упаковке сводит к минимуму риск коррозии или ударного повреждения., обеспечение доставки таких деталей, как блок цилиндров FAW в сборе, в идеальном состоянии.. Клиенты могут положиться на логистику FAW для обеспечения стабильного качества и надежности..