Welcome to this in-depth technical breakdown of the Unité de commande d'inclinaison de cabine FAW. This is the complete hydraulic and electric assembly responsible for lifting the entire cab-over-engine on the FAW Jiefang CA4251P66K24T1A3E5 6×4 tracteur semi-remorque diesel. This is one of the most critical safety and maintenance systems on the vehicle, as its “logique” is to provide technicians with safe, reliable access to the engine and transmission.

Le “Assemblage logique” designation for the Unité de commande d'inclinaison de cabine FAW est la clé. This is not one system, mais un “double logique” ou “hybride” système. It combines a primary ‘Electric pump assy’ (5002075B91W-C00) for effortless, push-button operation, with a secondary, “backup” ‘Manual pump assy’ (5002070B91W-C00). This built-in redundancy is a critical safety “logique,” ensuring that a technician can *always* lift the cab, even if the truck’s battery is dead.

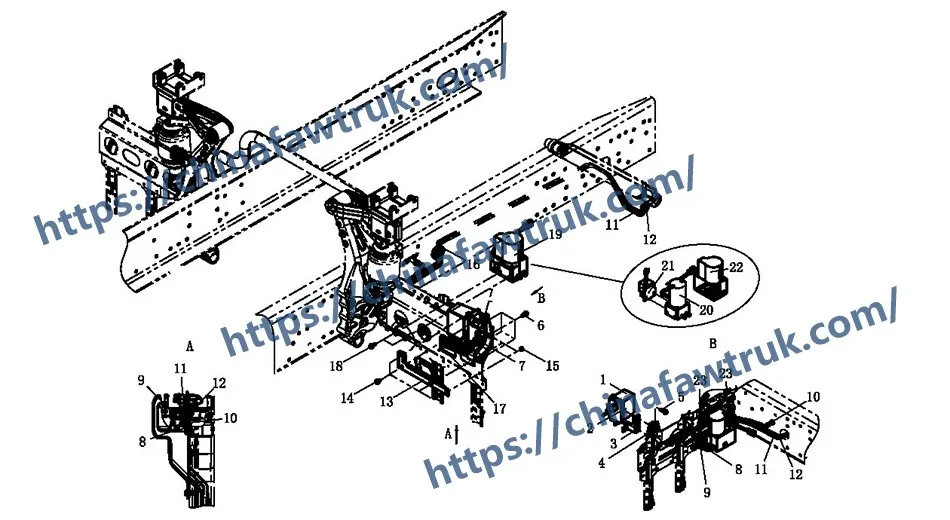

This expert guide is an essential resource for technicians and fleet operators. Nous déconstruirons l'ensemble Unité de commande d'inclinaison de cabine FAW dans son 23 types de composants. Nous analyserons le “Logique électrique” (the motor, pompe, and relay), le “Manual Logic” (the hand pump and switch), the shared “Hydraulic Network” (les durites), et le “Logique de fixation” (the critical anti-vibration hardware).

C'est le primaire, convenience-focused part of the Unité de commande d'inclinaison de cabine FAW. This system allows the driver or technician to lift the cab by simply pressing the ‘Hydraulic cab tilt switch assy’ (3735080-A01) à l'intérieur de la cabine.

1. ‘Electric pump assy’ (5002075B91W-C00): C'est le “brain and muscle” of the electric system. This MSU is an integrated unit that combines the hydraulic pump and the electric motor into one assembly.

2. ‘Electric pump motor’ (5002180AA01-C00): This is the high-torque, 24V DC motor that drives the pump. C'est “logique” is to provide high power for a short, intermittent duration. It draws a massive amount of current, which is why it cannot be wired directly to the dashboard switch.

3. ‘Electric pump relay assy’ (5002190B91W-C00): C'est le “logique” that makes the system safe. The in-cab switch (3735080-A01) sends a small, low-amperage signal to this relay. This relay (a heavy-duty solenoid) then closes, handling the massive, high-amperage current needed by the motor. This protects the cab’s wiring from melting. This relay is a critical MSU.

4. ‘Electric pump shield assy’ (5002185B91W-C00): This is the system’s “armor.” This MSU protects the entire electric pump assembly from road debris, water spray, and ice. A missing shield is a common cause of premature motor corrosion and failure.

C'est le “redundancy logic” built into the Unité de commande d'inclinaison de cabine FAW. This system ensures that even with a dead battery, a failed motor, or a blown relay, the cab can still be lifted for service.

1. ‘Manual pump – cab lift’ (5002070B91W-C00): This is the core of the manual system. It is a hydraulic hand pump, similar to a bottle jack. The technician inserts the truck’s jack handle (from the tool kit) into this pump’s socket and manually pumps it to raise the cab.

2. ‘Manual switch bracket assy’ (5002120B91W): This bracket holds the manual pump. Plus important encore, it holds the “changeover switch” ou “selector valve.” Le “logique” is that a technician must *first* turn this valve (often with the same jack handle) to change the hydraulic circuit from “electric mode” à “manual mode.” This prevents the manual pump from trying to push fluid “backwards” through the electric pump.

3. 'Joint’ (5002133B91W): This MSU provides the critical seal between the manual pump and its mounting bracket, preventing hydraulic fluid leaks under high pressure.

Ce groupe de MSU est le “plomberie” de la Unité de commande d'inclinaison de cabine FAW. These high-pressure hydraulic hoses are the arteries that connect *both* pumps to the main tilt cylinder.

1. The 3-Way Logic: 'Ensemble de tuyaux – connect pump to 3-way joint’ (5002085B91W-C00)

C'est le “logique” that allows the dual-pump system to work. Le “3-way joint” (or a T-junction) is the point where the fluid line from the electric pump and the fluid line from the manual pump *meet*. From this junction, a single line then proceeds to the main tilt cylinder. This hose is the MSU that makes this “combined” logic possible.

2. Le “Pousser/Tirer” Logique: (MSU 11 & 12)

The system uses a dual-action cylinder, which requires two hoses:

3. Protection & Routage (MSU 13, 16, 17):

Ce sont les points critiques, often-overlooked MSUs. A ‘Deflector plate’ (5002141B91W) and ‘Shield-hydraulic oil pipe’ (5002146B91W) protect these vital hoses from road debris, stone chips, and high heat from the exhaust. A ‘Rubber seal’ (3724032-50UN) protects a hose as it passes through a chassis member. A failure of these protective MSUs leads to a chafed, burst hose, qui est le #1 failure point for any hydraulic system.

L'ensemble Unité de commande d'inclinaison de cabine FAW is subject to massive vibration. The fastener system is not just hardware; it is an engineered “anti-vibration” logic to prevent the pumps from shaking themselves loose.

« Boulon combiné’ (CQ1461035, CQ1460825, CQ1460820): The parts list calls for a total of eight (8) de ceux-ci. Le “Combinaison” logic is the most important feature. Ces boulons ont un *captif, rondelle frein pré-fixée* (soit une rondelle élastique ou une tête dentelée). This lock washer provides constant tension, making it physically impossible for the bolt to back out from vibration.

«Écrou hexagonal’ (CQ34008): These four nuts are used on the other side of the bolts (Par exemple, CQ1460820). Ils sont à haute résistance, couple dominant “Nyloc” des noisettes. Their nylon insert binds to the threads, providing a *second layer* of anti-vibration logic. This dual-system (rondelle de blocage + contre-écrou) is what ensures the Unité de commande d'inclinaison de cabine FAW remains securely fastened for the life of the vehicle.

Le tableau suivant fournit l'intégralité, ventilation détaillée de tous 23 types de composants identifiés dans le Unité de commande d'inclinaison de cabine FAW schéma du tracteur FAW CA4251P66K24T1A3E5.

| Marque | Partie no. | Nom de la pièce | Quantité |

|---|---|---|---|

| 1 | 5002070B91W-C00 | Manual pump assy – cab lift | 1 |

| 2 | 5002133B91W | Joint | 1 |

| 3 | 5002131B91W | Manual switch fixed bracket | 1 |

| 4 | 5002120B91W | Manual switch bracket assy | 1 |

| 5 | CQ1461035 | Boulon combiné | 2 |

| 6 | CQ1460825 | Boulon combiné | 4 |

| 7 | 3735080-A01 | Hydraulic cab tilt switch assy | 1 |

| 8 | 5002090B91W-C00 | Main hydraulic hose assy | 1 |

| 9 | 5002095B91W-C00 | Connecting hose assy | 1 |

| 10 | 5002085B91W-C00 | Ensemble de tuyaux – connect pump to 3-way joint | 1 |

| 11 | 5002080B91W-C00 | Ensemble de tuyaux – hydraulic cylinder push oil port | 1 |

| 12 | 5002100B91W-C00 | Ensemble de tuyaux – hydraulic cylinder pull oil port | 1 |

| 13 | 5002141B91W | Deflector plate | 1 |

| 14 | CQ1460820 | Boulon combiné | 4 |

| 15 | CQ34008 | Écrou hexagonal | 4 |

| 16 | 3724032-50UN | Rubber seal | 1 |

| 17 | 5002146B91W | Shield-hydraulic oil pipe | 1 |

| 18 | CQ1460830 | Boulon combiné | 2 |

| 19 | 5002075B91W-C00 | Electric pump assy – cab lift | 1 |

| 20 | 5002180AA01-C00 | Electric pump motor assy – cab lift (see 5002075AA01-C00) | 1 |

| 21 | 5002190B91W-C00 | Electric pump relay assy – cab lift | 1 |

| 22 | 5002185B91W-C00 | Electric pump shield assy – cab lift | 1 |

| 23 | T67414646 | Sangle de retenue en plastique | 2 |

Les spécifications pour le Unité de commande d'inclinaison de cabine FAW are defined by its critical, dual-logic function. It combines a primary electric system for convenience and a manual backup system for safety and service redundancy.

| Demande de véhicule | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tracteur |

| Groupe de composants | Unité de commande d'inclinaison de cabine FAW |

| Type de système | Hybrid Hydraulic (Électrique / Manuel) |

| Logique primaire (Électrique) | ‘Electric pump assy’ (5002075B91W-C00) |

| Backup Logic (Manuel) | ‘Manual pump assy’ (5002070B91W-C00) |

| Control MSU (Électrique) | ‘Electric pump relay assy’ (5002190B91W-C00) |

| Control MSU (Switch) | ‘Hydraulic cab tilt switch assy’ (3735080-A01) |

| Hydraulic Logic | Dual-Action (Pousser/Tirer) via ‘3-way joint’ (5002085B91W-C00) |

| Système de tuyaux | 5x High-Pressure Hoses, 2x Shields, 2x Straps |

| Logique de fixation | Anti-vibrations (Boulons combinés & Locking Nuts) |

| Total des attaches | 10 Boulons combinés, 4 Hexagon Nuts |

Pièces FAW, y compris l'ensemble bloc-cylindres, sont emballés avec soin pour garantir une livraison en toute sécurité. Chaque composant est sécurisé dans des matériaux de protection pour éviter tout dommage pendant le transport. Le réseau logistique garantit des expéditions ponctuelles dans le monde entier, soutenir des opérations de maintenance efficaces. Vous trouverez ci-dessous une image illustrant l'emballage standard des pièces de camion FAW., mettant en valeur l’attention portée aux détails dans la manipulation et le stockage.

Cette approche d'emballage minimise le risque de corrosion ou de dommages causés par les chocs., s'assurer que les pièces comme l'ensemble bloc-cylindres FAW arrivent en parfait état. Les clients peuvent compter sur la logistique de FAW pour une qualité et une fiabilité constantes.