Bienvenido a este desglose técnico en profundidad del Unidad de control de inclinación de cabina FAW. This is the complete hydraulic and electric assembly responsible for lifting the entire cab-over-engine on the FAW Jiefang CA4251P66K24T1A3E5 6×4 tractor semirremolque diésel. This is one of the most critical safety and maintenance systems on the vehicle, as its “lógica” is to provide technicians with safe, reliable access to the engine and transmission.

El “Asamblea lógica” designation for the Unidad de control de inclinación de cabina FAW es clave. This is not one system, pero un “lógica dual” o “híbrido” sistema. It combines a primary ‘Electric pump assy’ (5002075B91W-C00) for effortless, push-button operation, with a secondary, “backup” ‘Manual pump assy’ (5002070B91W-C00). This built-in redundancy is a critical safety “lógica,” ensuring that a technician can *always* lift the cab, even if the truck’s battery is dead.

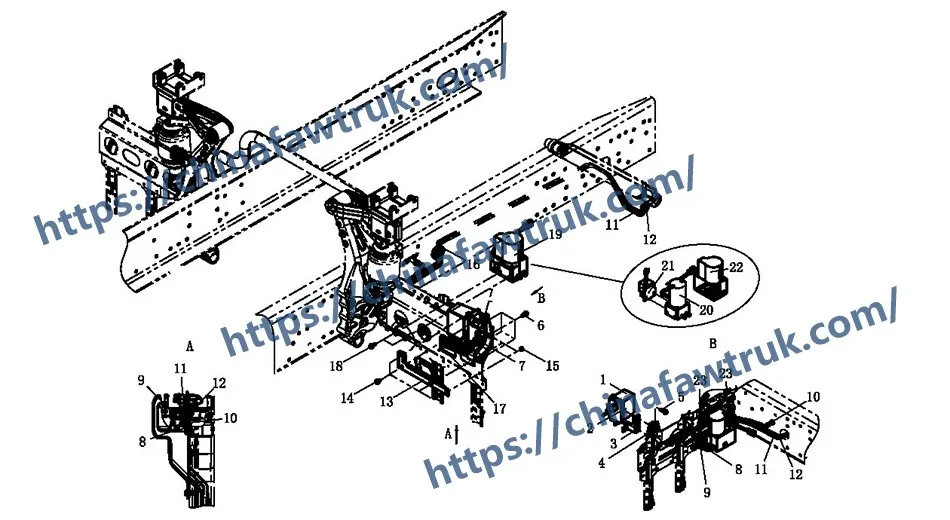

This expert guide is an essential resource for technicians and fleet operators. Deconstruiremos todo Unidad de control de inclinación de cabina FAW en su 23 tipos de componentes. Analizaremos el “Lógica eléctrica” (the motor, bomba, and relay), el “Manual Logic” (the hand pump and switch), the shared “Hydraulic Network” (the hoses), y el “Lógica de fijación” (the critical anti-vibration hardware).

Este es el principal, convenience-focused part of the Unidad de control de inclinación de cabina FAW. This system allows the driver or technician to lift the cab by simply pressing the ‘Hydraulic cab tilt switch assy’ (3735080-A01) dentro de la cabina.

1. ‘Electric pump assy’ (5002075B91W-C00): Este es el “brain and muscle” of the electric system. This MSU is an integrated unit that combines the hydraulic pump and the electric motor into one assembly.

2. ‘Electric pump motor’ (5002180AA01-C00): This is the high-torque, 24V DC motor that drives the pump. Es “lógica” is to provide high power for a short, intermittent duration. It draws a massive amount of current, which is why it cannot be wired directly to the dashboard switch.

3. ‘Electric pump relay assy’ (5002190B91W-C00): Este es el “lógica” that makes the system safe. The in-cab switch (3735080-A01) sends a small, low-amperage signal to this relay. This relay (a heavy-duty solenoid) then closes, handling the massive, high-amperage current needed by the motor. This protects the cab’s wiring from melting. This relay is a critical MSU.

4. ‘Electric pump shield assy’ (5002185B91W-C00): This is the system’s “armor.” This MSU protects the entire electric pump assembly from road debris, water spray, y hielo. A missing shield is a common cause of premature motor corrosion and failure.

Este es el “redundancy logic” built into the Unidad de control de inclinación de cabina FAW. This system ensures that even with a dead battery, a failed motor, or a blown relay, the cab can still be lifted for service.

1. ‘Manual pump – cab lift’ (5002070B91W-C00): This is the core of the manual system. It is a hydraulic hand pump, similar to a bottle jack. The technician inserts the truck’s jack handle (from the tool kit) into this pump’s socket and manually pumps it to raise the cab.

2. ‘Manual switch bracket assy’ (5002120B91W): This bracket holds the manual pump. Más importante aún, it holds the “changeover switch” o “selector valve.” El “lógica” is that a technician must *first* turn this valve (often with the same jack handle) to change the hydraulic circuit from “electric mode” a “manual mode.” This prevents the manual pump from trying to push fluid “backwards” through the electric pump.

3. 'Empaquetadora’ (5002133B91W): This MSU provides the critical seal between the manual pump and its mounting bracket, preventing hydraulic fluid leaks under high pressure.

Este grupo de MSU es el “plomería” del Unidad de control de inclinación de cabina FAW. These high-pressure hydraulic hoses are the arteries that connect *both* pumps to the main tilt cylinder.

1. The 3-Way Logic: ‘Hose assy – connect pump to 3-way joint’ (5002085B91W-C00)

Este es el “lógica” that allows the dual-pump system to work. El “3-way joint” (or a T-junction) is the point where the fluid line from the electric pump and the fluid line from the manual pump *meet*. From this junction, a single line then proceeds to the main tilt cylinder. This hose is the MSU that makes this “combined” logic possible.

2. El “Empujar/tirar” Lógica: (MSU 11 & 12)

The system uses a dual-action cylinder, which requires two hoses:

3. Protección & Enrutamiento (MSU 13, 16, 17):

Estos son los críticos, often-overlooked MSUs. A ‘Deflector plate’ (5002141B91W) and ‘Shield-hydraulic oil pipe’ (5002146B91W) protect these vital hoses from road debris, stone chips, and high heat from the exhaust. A ‘Rubber seal’ (3724032-50A) protects a hose as it passes through a chassis member. A failure of these protective MSUs leads to a chafed, burst hose, cual es el #1 failure point for any hydraulic system.

todo el Unidad de control de inclinación de cabina FAW is subject to massive vibration. The fastener system is not just hardware; it is an engineered “antivibración” logic to prevent the pumps from shaking themselves loose.

«Perno combinado’ (CQ1461035, CQ1460825, CQ1460820): The parts list calls for a total of eight (8) de estos. El “Combinación” logic is the most important feature. Estos pernos tienen un *cautivo, arandela de seguridad preinstalada* (ya sea una arandela de resorte o una cabeza dentada). This lock washer provides constant tension, making it physically impossible for the bolt to back out from vibration.

«Tuerca hexagonal’ (CQ34008): These four nuts are used on the other side of the bolts (P.EJ., CQ1460820). Son de alta resistencia, par predominante “niloc” nueces. Their nylon insert binds to the threads, providing a *second layer* of anti-vibration logic. This dual-system (arandela de seguridad + tuerca de bloqueo) is what ensures the Unidad de control de inclinación de cabina FAW remains securely fastened for the life of the vehicle.

La siguiente tabla proporciona la información completa, desglose detallado de todos 23 tipos de componentes identificados en el Unidad de control de inclinación de cabina FAW diagrama para el tractor FAW CA4251P66K24T1A3E5.

| Marca | Número de pieza. | Nombre de la pieza | Cantidad |

|---|---|---|---|

| 1 | 5002070B91W-C00 | Manual pump assy – cab lift | 1 |

| 2 | 5002133B91W | Empaquetadora | 1 |

| 3 | 5002131B91W | Manual switch fixed bracket | 1 |

| 4 | 5002120B91W | Manual switch bracket assy | 1 |

| 5 | CQ1461035 | Perno combinado | 2 |

| 6 | CQ1460825 | Perno combinado | 4 |

| 7 | 3735080-A01 | Hydraulic cab tilt switch assy | 1 |

| 8 | 5002090B91W-C00 | Main hydraulic hose assy | 1 |

| 9 | 5002095B91W-C00 | Connecting hose assy | 1 |

| 10 | 5002085B91W-C00 | Hose assy – connect pump to 3-way joint | 1 |

| 11 | 5002080B91W-C00 | Hose assy – hydraulic cylinder push oil port | 1 |

| 12 | 5002100B91W-C00 | Hose assy – hydraulic cylinder pull oil port | 1 |

| 13 | 5002141B91W | Deflector plate | 1 |

| 14 | CQ1460820 | Perno combinado | 4 |

| 15 | CQ34008 | Tuerca hexagonal | 4 |

| 16 | 3724032-50A | Rubber seal | 1 |

| 17 | 5002146B91W | Shield-hydraulic oil pipe | 1 |

| 18 | CQ1460830 | Perno combinado | 2 |

| 19 | 5002075B91W-C00 | Electric pump assy – cab lift | 1 |

| 20 | 5002180AA01-C00 | Electric pump motor assy – cab lift (see 5002075AA01-C00) | 1 |

| 21 | 5002190B91W-C00 | Electric pump relay assy – cab lift | 1 |

| 22 | 5002185B91W-C00 | Electric pump shield assy – cab lift | 1 |

| 23 | T67414646 | Correa de retención de plástico | 2 |

Las especificaciones para el Unidad de control de inclinación de cabina FAW se definen por su criticidad, dual-logic function. It combines a primary electric system for convenience and a manual backup system for safety and service redundancy.

| Solicitud de vehículo | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Grupo de componentes | Unidad de control de inclinación de cabina FAW |

| Tipo de sistema | Hybrid Hydraulic (Eléctrico / Manual) |

| Lógica primaria (Eléctrico) | ‘Electric pump assy’ (5002075B91W-C00) |

| Backup Logic (Manual) | ‘Manual pump assy’ (5002070B91W-C00) |

| Control MSU (Eléctrico) | ‘Electric pump relay assy’ (5002190B91W-C00) |

| Control MSU (Cambiar) | ‘Hydraulic cab tilt switch assy’ (3735080-A01) |

| Lógica Hidráulica | Dual-Action (Empujar/tirar) via ‘3-way joint’ (5002085B91W-C00) |

| Sistema de manguera | 5x High-Pressure Hoses, 2x Shields, 2x Straps |

| Lógica de sujetadores | Antivibración (Pernos combinados & Locking Nuts) |

| sujetadores totales | 10 Pernos combinados, 4 Nueces hexágono |

piezas FAW, incluido el conjunto del bloque de cilindros, Se empaquetan con cuidado para garantizar una entrega segura.. Cada componente está asegurado con materiales protectores para evitar daños durante el transporte.. La red logística garantiza envíos puntuales en todo el mundo., apoyando operaciones de mantenimiento eficientes. A continuación se muestra una imagen que ilustra el embalaje estándar de las piezas de camiones FAW., mostrando la atención al detalle en el manejo y almacenamiento.

Este enfoque de embalaje minimiza el riesgo de corrosión o daños por impacto., asegurando que piezas como el conjunto de bloque de cilindros FAW lleguen en perfectas condiciones. Los clientes pueden confiar en la logística de FAW para obtener calidad y confiabilidad constantes.