Welcome to this essential expert breakdown of the FAW Fuse Box Assembly 1 – With Relay. This specific component is a critical electrical distribution and safety hub found in the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor. As an auxiliary module (designated “Assembly 1”), its “logic” is to provide a centralized, protected, and switchable power source for a specific group of high-amperage accessories, all while being isolated from the main cab fuse box.

The FAW Fuse Box Assembly 1 – With Relay (Part No. 3722020B91W) is a self-contained unit that combines two distinct electrical functions: circuit protection (fuses) and circuit control (relays). This “logic” of combination is vital for modern truck electronics. It simplifies wiring, centralizes fault-finding, and isolates high-power devices from sensitive dashboard switches. A failure in this box could disable critical auxiliary systems, making its proper service a key maintenance task.

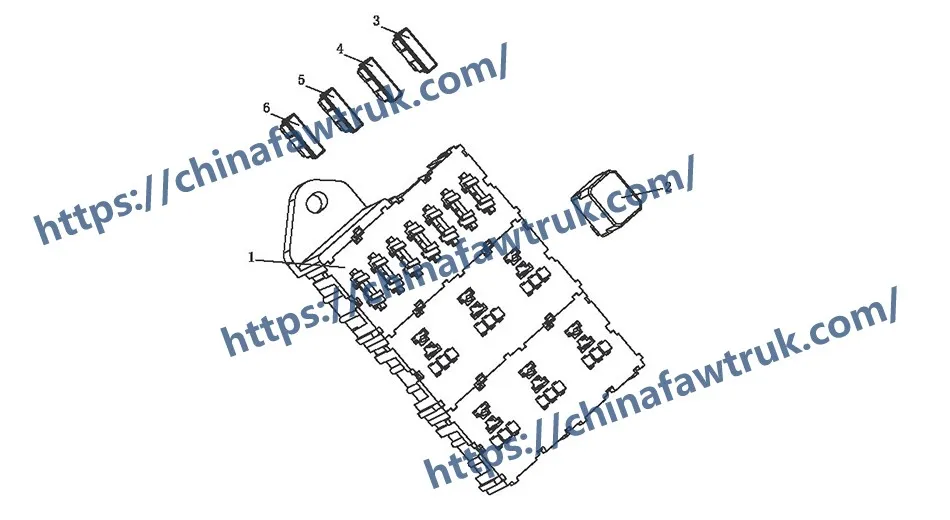

This in-depth guide is designed for technicians and parts specialists. We will deconstruct the entire FAW Fuse Box Assembly 1 – With Relay into its three core component types: the main structural housing, the ‘Four-pin relay’ (3752015-91W) assemblies, and the full set of blade-type fuses (5A, 10A, 15A, 20A). Understanding each of these minimum serviceable units (MSUs) is essential for rapid diagnostics and cost-effective repairs.

The ‘Fuse box assembly 1-with relay’ (3722020B91W) is the primary structural component. This is the main “large purchase item” and serves as the foundation for all the serviceable units it contains. Its function goes far beyond being a simple plastic box.

Internal Logic: The housing’s true “logic” is internal. It contains a network of copper busbars and electrical pathways. These busbars are responsible for distributing the main power input (from the battery) to the “hot” side of each fuse and relay socket. This pre-engineered internal wiring eliminates a “rat’s nest” of external wires, increasing reliability and reducing potential points of failure.

Construction and Durability: This part of the FAW Fuse Box Assembly 1 – With Relay is constructed from high-grade, heat-resistant, and impact-resistant polymers. It is designed to be mounted in the engine bay or on the chassis, exposing it to vibration, moisture, and extreme temperatures.

Therefore, it always includes a weather-proof gasket on its locking cover. A failed gasket is a common source of problems, as it allows water ingress, which leads to pin corrosion and electrical shorts.

Serviceability: The housing itself is *not* a typical MSU. It is only replaced in the event of catastrophic failure, such as physical cracks from an impact, melting from a severe electrical fire, or internal busbar corrosion that is beyond cleaning. For all other faults, the MSUs are the components *inside* it.

This is the “longer” and more detailed section, as these relays are the primary “logic” actuators in the FAW Fuse Box Assembly 1 – With Relay. The parts list calls for five of these ‘Four-pin relay assy’ (3752015-91W) components.

What is a Relay? A relay is an electromagnetic switch. Its function is to allow a very low-power electrical circuit to control a very high-power electrical circuit safely. A 24V dashboard switch, for example, cannot handle the 20-30 amps required to run a high-power device like a fuel heater or a bank of fog lights. Running that much current into the cab would require thick, heavy, and expensive copper wires and a dangerously large switch.

The “Four-Pin” Logic: The relay solves this. The “logic” of a standard 4-pin (ISO) relay is simple and brilliant:

When the driver flips the dashboard switch, it sends a low-power signal to pins 85/86. The electromagnet “clicks,” pulling a physical lever (armature) inside the relay, which closes the high-power connection between Pin 30 and Pin 87. This instantly sends the high-amperage current to the device.

Failure & Serviceability: Relays are the most common electro-mechanical failure point in any vehicle. Because they have moving parts, the internal contacts can become “pitted” or carbonized from arcing, leading to a poor connection (the device works intermittently). Alternatively, the contacts can “weld” themselves shut from a current surge (the device won’t turn off). Finally, the low-power coil (85/86) can simply burn out (the device won’t turn on, and the relay makes no “click”).

The ‘Four-pin relay assy’ is the definition of a Minimum Serviceable Unit (MSU). It is designed to be “plug-and-play.” A technician can quickly test a relay by swapping it with a known good one (since there are 5 identical units in the box). This makes diagnosis in the field extremely efficient, which is the entire purpose of the FAW Fuse Box Assembly 1 – With Relay design.

The second category of MSUs within the FAW Fuse Box Assembly 1 – With Relay is the set of ‘Blade-type fuses’ (片式熔断器). These are the “sacrificial” components of the electrical system.

The Logic of Protection: A fuse’s only job is to fail. It is a “logic” device that senses an overcurrent condition (e.g., from a short circuit or a failing component) and instantly “blows.” A small metal link inside the fuse melts, creating an open circuit and cutting off power.

This sacrificial failure is critical. It protects the two most expensive parts of the circuit: the wiring harness (which can melt and cause a fire) and the end-component (like a sensitive ECU or expensive lighting assembly). A $0.20 fuse saves a $500 component.

Deconstructing the Fuse List: The FAW Fuse Box Assembly 1 – With Relay is populated with a specific set of fuses, each with a purpose:

These fuses are the most common MSU. They are color-coded, and their transparent plastic housing allows for instant visual inspection of the internal link, making them the easiest component to diagnose and replace.

The following table is the complete parts breakdown for the FAW Fuse Box Assembly 1 – With Relay, as specified for the FAW CA4251P66K24T1A3E5. It details the main housing and all associated serviceable relays and fuses.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 3722020B91W | Fuse box assembly 1-with relay (see drawing) | 1 |

| 2 | 3752015-91W | Four-pin relay assy | 5 |

| 3 | 3722011-50 | 5A Blade-type fuse | 2 |

| 4 | 3722012-50 | 10A Blade-type fuse (see 3722011-50) | 2 |

| 5 | 3722013-50 | 15A Blade-type fuse (see 3722011-50) | 1 |

| 6 | 3722014-50 | 20A Blade-type fuse (see 3722011-50) | 1 |

The specifications for the FAW Fuse Box Assembly 1 – With Relay are defined by its role as an auxiliary power distribution and protection module. It is a fully-integrated unit designed for high-vibration, high-demand environments.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | FAW Fuse Box Assembly 1 – With Relay |

| Main Assembly Part No. | 3722020B91W |

| System Type | Auxiliary Electrical Protection & Switching Module |

| System Voltage | 24V DC (Nominal) |

| MSU 1 (Switching) | ‘Four-pin relay assy’ (P/N: 3752015-91W) |

| MSU 1 Quantity | 5 Units |

| MSU 2 (Protection) | Blade-Type Fuses (ATO/ATC) |

| Fuse Amperages | 5A (x2), 10A (x2), 15A (x1), 20A (x1) |

| Total Fuse Sockets | 6 (Populated) |

| Housing | Sealed polymer with internal busbars and locking cover |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.