Welcome to this critical technical guide on the FAW Front Lateral Stabiliser Bar Boom Bracket Logical Assembly (Assembly 507). This is the complete “chassis-side” mounting system for the stabilizer bar “booms” (end links) on the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor. This is a critical safety component for vehicle stability and handling.

The FAW Front Lateral Stabiliser Bar Boom Bracket Logical Assembly‘s “logic” is to provide the fixed, unyielding “anchor point” on the truck’s frame. The stabilizer bar system (see Assembly 506) works by twisting, and it can only twist if its ends are anchored. This assembly provides that crucial anchor.

This in-depth guide is an essential resource for professional suspension technicians and parts specialists. We will deconstruct the entire FAW Front Lateral Stabiliser Bar Boom Bracket Logical Assembly into its 10 serviceable components (across 5 part numbers), including the main ‘Brackets’ (2906441-92V) and the critical high-tensile fasteners that secure this high-stress system to the chassis.

The heart of the FAW Front Lateral Stabiliser Bar Boom Bracket Logical Assembly is the ‘Bracket-Front lateral stabiliser bar boom’ (2906441-92V). The parts list calls for two of these, one for the left side and one for the right side of the truck’s frame.

This is a heavy-duty, forged or fabricated steel bracket. Its sole function is to act as the **chassis-side anchor point** for the “boom” (also known as the “end link” or “drop link,” part number 2906320-92V from assembly 506). This bracket is bolted directly to the truck’s main C-channel frame rail using the ‘Hex head flange bolts’ (Q1851450T) and ‘Hex flange nuts’ (Q39714).

This component must be incredibly strong. It is the “reaction point” for the entire anti-roll system. When the truck corners and the stabilizer bar twists, it transfers thousands of pounds of force from the axle, through the boom, and *into this bracket*, which then dissipates that force into the truck’s frame. A crack, bend, or loose bolt on this bracket will render the entire FAW Front Lateral Stabiliser Bar Boom Bracket Logical Assembly useless.

To understand the importance of the FAW Front Lateral Stabiliser Bar Boom Bracket Logical Assembly, one must understand the physics of a heavy truck in a turn.

**1. The Problem (Body Roll):** When a truck with a high center of gravity (like the CA4251P66K24T1A3E5) enters a corner, centrifugal force pushes the truck’s mass to the *outside* of the turn. This causes the entire cab and frame to “lean” or “roll” over. This is dangerous. It compresses the outside suspension (e.g., the right leaf spring in a left turn) and “unloads” the inside suspension. This “unloading” can lift the inside tire off the pavement, drastically reducing steering grip and braking power.

**2. The Solution (The Stabilizer Bar System):** The FAW Front Lateral Stabiliser Bar Boom Bracket Logical Assembly is a key part of the solution. The stabilizer bar (assembly 506) is a torsional spring (a “twist-bar”) that connects the left and right sides of the axle *indirectly*.

**3. The “Logic” of Force Transfer:**

When the truck rolls, the axle and frame move relative to each other. This pushes the “boom” on one side and pulls the “boom” on the other. This movement, anchored by the FAW Front Lateral Stabiliser Bar Boom Bracket Logical Assembly, is what twists the stabilizer bar. The bar’s resistance to this twist is what keeps the truck level. Therefore, without this simple, solid bracket, the entire anti-roll system would fail, as the booms would have nothing to push against.

The “connecting components” of the FAW Front Lateral Stabiliser Bar Boom Bracket Logical Assembly are the critical, high-tensile fasteners that secure the brackets to the chassis. A safety system is only as strong as its weakest link, and these bolts are designed to be unbreakable.

**’Hex head flange bolt’ (Q1851450T) – 4 units:** These are the primary structural bolts. The “flange” head is an integrated, non-spinning washer. This is critical for two reasons: it spreads the clamping load over a wider area of the chassis frame, and it allows for one-person installation. The “T” suffix denotes a high-tensile strength class (e.g., 10.9 or 12.9) with a protective coating, designed to handle extreme shear forces.

**’Hex flange nut’ (Q39714) – 4 units:** These are the nuts that pair with the bolts. These are “flange” nuts to match the bolts, providing a wide clamping surface. More importantly, these are “lock nuts.” They feature a prevailing-torque design (either a nylon insert or an “oval-lock” crimp) that grips the threads of the bolt. This is the “logic” that prevents the nut from ever vibrating loose, even under the constant, high-frequency vibration of a diesel engine and road shock.

These 8 fasteners (4 bolts, 4 nuts) are the only things holding the FAW Front Lateral Stabiliser Bar Boom Bracket Logical Assembly to the truck. Using a standard, non-flange, non-locking, lower-grade (e.g., 8.8) bolt and nut from a hardware store would be a critical safety error, as they would quickly vibrate loose or shear, causing the stabilizer system to fail.

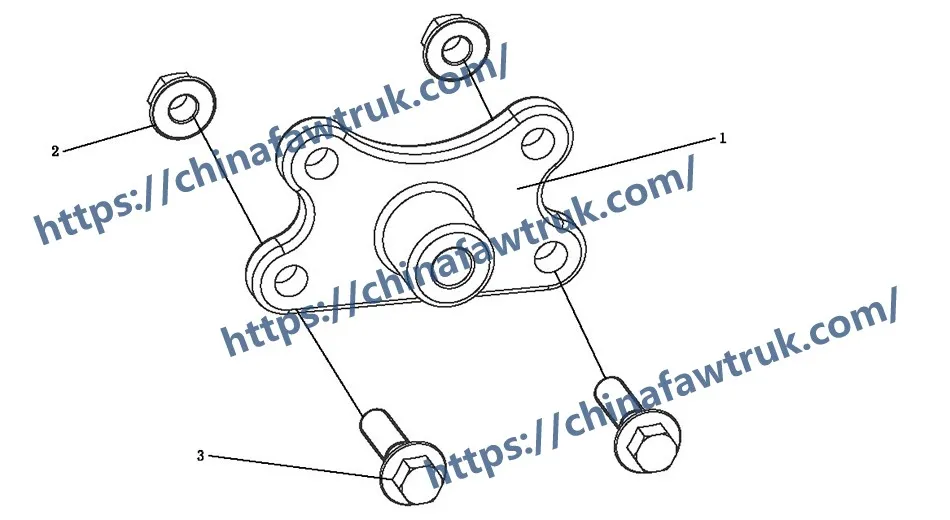

The following table provides the complete, detailed breakdown of all 3 component types (totaling 10 pieces) identified in the ‘Front Lateral Stabiliser Bar Boom Bracket Logical Assembly’ (507) diagram for the FAW CA4251P66K24T1A3E5 tractor.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 2906441-92V | Bracket-Front lateral stabiliser bar boom | 2 |

| 2 | Q39714 | Hex flange nut | 4 |

| 3 | Q1851450T | Hex head flange bolt | 4 |

The specifications for the FAW Front Lateral Stabiliser Bar Boom Bracket Logical Assembly are defined by its function as the rigid, chassis-side anchor for the anti-roll system. The FAW Front Lateral Stabiliser Bar Boom Bracket Logical Assembly is a key component for vehicle stability.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | FAW Front Lateral Stabiliser Bar Boom Bracket Logical Assembly |

| Common Name | Stabilizer Bar End Link Frame Bracket |

| Main Bracket P/N | 2x (Part No. 2906441-92V) |

| Material (Typical) | High-Strength Fabricated Steel |

| Mounting Location | Chassis Frame Rail |

| Fastener Bolts | 4x Hex Head Flange Bolts (Q1851450T) |

| Fastener Nuts | 4x Hex Flange Lock Nuts (Q39714) | Other

| Mating Assembly | FAW Stabiliser Bar & Boom Assembly (Assembly 506) |

| Primary Function | To provide the rigid, structural anchor point on the chassis for the stabilizer bar end links (booms). |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.