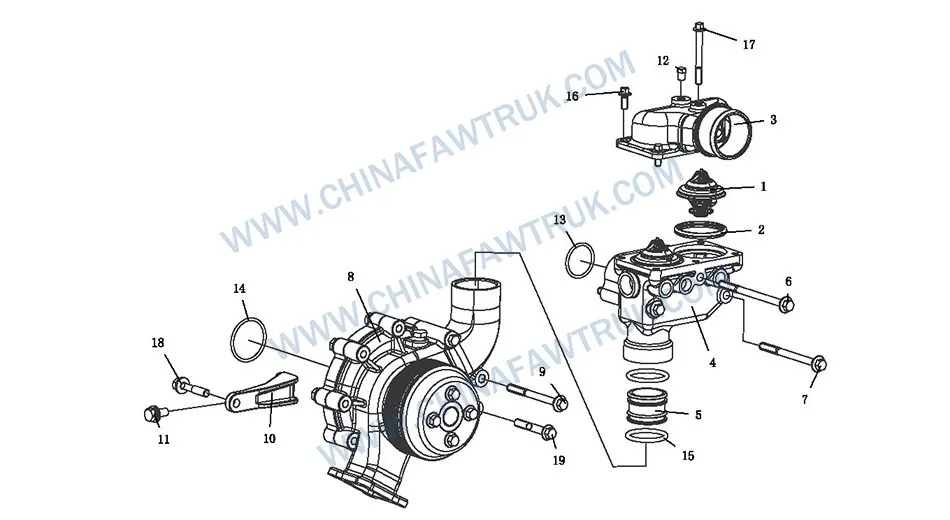

Bomba de agua rusa FAW: 18 Componentes para una circulación de enfriamiento perfecta en el Ártico

El Bomba de agua rusa FAW is the hydrodynamic heart of the CA3250P66K24L1TE5Z engine. Engineered to circulate high-viscosity coolant in sub-zero temperatures, this assembly ensures uniform thermal distribution across the block. This guide details the impeller technology, sealing architecture, and integrated housing logic required for reliable winter operations.

Bomba de agua rusa FAW

Core Dynamics: Impeller and Housing Design

The primary functional unit of the system is the Water Pump Assembly (Número de pieza. 1307010-55R). En el contexto de la Bomba de agua rusa FAW, this component is engineered to handle the specific fluid dynamics of cold glycol mixtures. The impeller geometry is designed to prevent cavitation, a phenomenon where low-pressure bubbles form and collapse, pitting the metal surfaces.

En el Ártico ruso, coolant can become thick and syrupy at -40°C. A standard impeller might shear or cavitate under these conditions, failing to establish flow. El Bomba de agua rusa FAW utilizes a reinforced impeller shaft and high-torque vane profile to push this viscous fluid effectively, ensuring that the cylinder head receives immediate cooling flow upon startup.

The pump housing serves as the central manifold for the cooling system. It integrates with the Thermostat Seat (Número de pieza. 1306021-51B) to form a unified thermal management module. This integration reduces external plumbing, minimizing leak points. The casting quality of the Bomba de agua rusa FAW es critico; it must be free of porosity to withstand system pressures exceeding 15 PSI without weeping coolant.

Además, the bearing support within the Bomba de agua rusa FAW assembly is sealed for life. It is designed to handle the high radial loads imposed by the poly-V belt drive system. If the bearing fails, the pump shaft will wobble, destroying the dynamic seal and leading to rapid coolant loss. FAW uses premium bearing steel to ensure longevity in these high-load conditions.

Lógica de sellado: O-Rings and Static Seals

Reliability in the Bomba de agua rusa FAW system is defined by its ability to hold fluid under pressure. The assembly utilizes a complex array of static seals, incluyendo el Hydraulic Pneumatic O-Ring Rubber Seal (Número de pieza. CQ7343412C) and larger variants like Part No. CQ345462C. These are not standard rubber rings; they are formulated from high-grade EPDM.

EPDM (Ethylene Propylene Diene Monomer) is chosen for the Bomba de agua rusa FAW because of its exceptional resistance to heat, ozono, and chemical degradation from antifreeze additives. In the extreme thermal cycling of the Russian climate—where engines go from -40°C to +90°C daily—these seals must expand and contract without losing elasticity or cracking.

The interface between the pump and the thermostat housing is critical. El Thermostat Sealing Ring (Número de pieza. 1306011-29D) ensures that coolant does not bypass the thermostat valve. A leak here in the Bomba de agua rusa FAW system would allow coolant to circulate to the radiator prematurely, preventing the engine from reaching operating temperature and increasing fuel consumption and engine wear.

Proper installation of these seals requires lubrication with clean coolant or a compatible assembly grease. Installing them dry can cause the O-ring to roll or pinch, creating an immediate leak path. The machined grooves in the Bomba de agua rusa FAW housing are toleranced to provide the exact amount of “crush” needed to energize the seal without extruding it.

Rigid Mounting: Brackets and Fasteners

El Bomba de agua rusa FAW is secured to the engine block via a robust mounting strategy. El Water Pump Bracket (Número de pieza. 1307046-81D) acts as the primary anchor. This bracket must be rigid enough to resist the bending moments applied by the belt tensioner. Any flex in this bracket would lead to belt misalignment and premature pump bearing failure.

Fastening duties are handled by high-strength bolts, such as the Tornillo – For Water Pump (Número de pieza. 1307019-81D) y el Perno de brida hexagonal (Número de pieza. Q1840820). The flange head design is standard on the Bomba de agua rusa FAW to distribute clamping load over the aluminum housing, preventing stress fractures around the bolt holes.

For areas requiring component stacking, el Perno combinado (Número de pieza. CQ1461025) se usa. These bolts feature integrated washers that bite into the mating surface, providing resistance to vibrational loosening. En el Bomba de agua rusa FAW solicitud, maintaining torque on these bolts is vital, as a loose pump will eventually fret against the block face, ruining the sealing surface.

The assembly also includes the Small Cycle Connecting Pipe (Número de pieza. 1306023-53D). This pipe connects the pump to the bypass circuit, allowing coolant to recirculate within the block during warm-up. The structural integrity of this pipe and its connections to the Bomba de agua rusa FAW are essential for the proper functioning of the thermostat bypass logic.

Lista de desglose de componentes

La siguiente tabla es la completa., itemized breakdown of the Bomba de agua rusa FAW and integrated thermostat assembly. Every component listed, from the main pump body to the smallest sealing ring, is critical for the leak-free operation of the cooling system.

| No. |

Número de pieza |

Nombre de la pieza |

Cantidad |

| 1 |

1306010-81D |

Ensamblaje del termostato |

2 |

| 2 |

1306011-29D |

Thermostat Sealing Ring |

2 |

| 3 |

1306013-81D |

Thermostat Upper Cover |

1 |

| 4 |

1306021-51B |

Thermostat Seat |

1 |

| 5 |

1306023-53D |

Small Cycle Connecting Pipe |

1 |

| 6 |

1306062-81D |

Tornillo – For Thermostat |

1 |

| 7 |

1306063-81D |

Tornillo – For Thermostat |

2 |

| 8 |

1307010-55R |

Water Pump Assembly |

1 |

| 9 |

1307019-81D |

Tornillo – For Water Pump |

2 |

| 10 |

1307046-81D |

Water Pump Bracket |

1 |

| 11 |

CQ1461025 |

Perno combinado |

1 |

| 12 |

CQ61801 |

Hexagon Head Taper Screw Plug |

1 |

| 13 |

CQ7343412C |

Hydraulic Pneumatic O-Ring Rubber Seal |

2 |

| 14 |

CQ343530C |

Hydraulic Pneumatic O-Ring Rubber Seal |

1 |

| 15 |

CQ345462C |

Hydraulic Pneumatic O-Ring Rubber Seal |

2 |

| 16 |

Q1840820 |

Perno de brida hexagonal (Vástago grueso/estándar) |

5 |

| 17 |

CQ1461055 |

Perno combinado |

1 |

| 18 |

Q1841065 |

Perno de brida hexagonal (Vástago grueso/estándar) |

2 |

Diagnostic Protocols for Pump Health

inspeccionando el Bomba de agua rusa FAW begins with the weep hole. A small amount of coolant seepage is normal during the break-in period, but continuous dripping indicates a failed internal mechanical seal. If coolant is visible at the weep hole, el Water Pump Assembly must be replaced immediately to prevent bearing washout and seizure.

Compruebe el Water Pump Bracket for stress cracks. Vibration from the heavy-duty diesel engine can fatigue the metal, especially if the mounting bolts have been over-torqued. A cracked bracket will lead to belt misalignment, causing the pump pulley to wobble and shred the drive belt.

Finalmente, inspect all Hydraulic Pneumatic O-Ring Rubber Seals during any disassembly. If the rubber feels hard or flattened, it has lost its sealing capability. Reusing old O-rings in the Bomba de agua rusa FAW system is a guaranteed recipe for leaks. Always lubricate new seals with clean coolant before installation to ensure they seat correctly without tearing.

Conclusión: The Flow of Reliability

El Bomba de agua rusa FAW is a robust component designed to meet the extreme demands of the Russian climate. Its reinforced impeller and high-quality bearings ensure consistent coolant flow, protecting the engine from thermal stress. The integrated housing design simplifies maintenance while maximizing structural rigidity.

Para propietarios de flotas, there is no substitute for genuine parts. Aftermarket water pumps often use inferior seal materials and weaker castings that cannot survive the harsh vibration and temperature extremes of the Bomba de agua rusa FAW operating environment. By investing in the genuine article, you ensure that your fleet remains cool, eficiente, and operational, milla tras milla.

Embalaje y Logística

piezas FAW, incluido el conjunto del bloque de cilindros, Se empaquetan con cuidado para garantizar una entrega segura.. Cada componente está asegurado con materiales protectores para evitar daños durante el transporte.. La red logística garantiza envíos puntuales en todo el mundo., apoyando operaciones de mantenimiento eficientes. A continuación se muestra una imagen que ilustra el embalaje estándar de las piezas de camiones FAW., mostrando la atención al detalle en el manejo y almacenamiento.

Este enfoque de embalaje minimiza el riesgo de corrosión o daños por impacto., asegurando que piezas como el conjunto de bloque de cilindros FAW lleguen en perfectas condiciones. Los clientes pueden confiar en la logística de FAW para obtener calidad y confiabilidad constantes.