Русский водяной насос FAW: 18 Компоненты для безупречной циркуляции холода в Арктике

The Русский водяной насос FAW is the hydrodynamic heart of the CA3250P66K24L1TE5Z engine. Engineered to circulate high-viscosity coolant in sub-zero temperatures, this assembly ensures uniform thermal distribution across the block. This guide details the impeller technology, sealing architecture, and integrated housing logic required for reliable winter operations.

Русский водяной насос FAW

Core Dynamics: Impeller and Housing Design

Основной функциональной единицей системы является Сборка водяного насоса (Часть №. 1307010-55р). В контексте Русский водяной насос FAW, this component is engineered to handle the specific fluid dynamics of cold glycol mixtures. The impeller geometry is designed to prevent cavitation, a phenomenon where low-pressure bubbles form and collapse, pitting the metal surfaces.

В Российской Арктике, coolant can become thick and syrupy at -40°C. A standard impeller might shear or cavitate under these conditions, failing to establish flow. The Русский водяной насос FAW utilizes a reinforced impeller shaft and high-torque vane profile to push this viscous fluid effectively, ensuring that the cylinder head receives immediate cooling flow upon startup.

The pump housing serves as the central manifold for the cooling system. It integrates with the Thermostat Seat (Часть №. 1306021-51Б) to form a unified thermal management module. This integration reduces external plumbing, minimizing leak points. The casting quality of the Русский водяной насос FAW имеет решающее значение; it must be free of porosity to withstand system pressures exceeding 15 PSI without weeping coolant.

Более того, the bearing support within the Русский водяной насос FAW assembly is sealed for life. It is designed to handle the high radial loads imposed by the poly-V belt drive system. If the bearing fails, the pump shaft will wobble, destroying the dynamic seal and leading to rapid coolant loss. FAW uses premium bearing steel to ensure longevity in these high-load conditions.

Логика уплотнения: O-Rings and Static Seals

Reliability in the Русский водяной насос FAW system is defined by its ability to hold fluid under pressure. The assembly utilizes a complex array of static seals, в том числе Hydraulic Pneumatic O-Ring Rubber Seal (Часть №. CQ7343412C) and larger variants like Part No. CQ7345462C. These are not standard rubber rings; they are formulated from high-grade EPDM.

ЭПДМ (Этилен-пропилен-диеновый мономер) is chosen for the Русский водяной насос FAW because of its exceptional resistance to heat, озон, and chemical degradation from antifreeze additives. In the extreme thermal cycling of the Russian climate—where engines go from -40°C to +90°C daily—these seals must expand and contract without losing elasticity or cracking.

The interface between the pump and the thermostat housing is critical. The Thermostat Sealing Ring (Часть №. 1306011-29Д) ensures that coolant does not bypass the thermostat valve. A leak here in the Русский водяной насос FAW system would allow coolant to circulate to the radiator prematurely, preventing the engine from reaching operating temperature and increasing fuel consumption and engine wear.

Proper installation of these seals requires lubrication with clean coolant or a compatible assembly grease. Installing them dry can cause the O-ring to roll or pinch, creating an immediate leak path. The machined grooves in the Русский водяной насос FAW housing are toleranced to provide the exact amount of “раздавить” needed to energize the seal without extruding it.

Rigid Mounting: Brackets and Fasteners

The Русский водяной насос FAW is secured to the engine block via a robust mounting strategy. The Water Pump Bracket (Часть №. 1307046-81Д) acts as the primary anchor. This bracket must be rigid enough to resist the bending moments applied by the belt tensioner. Any flex in this bracket would lead to belt misalignment and premature pump bearing failure.

Fastening duties are handled by high-strength bolts, such as the Болт – For Water Pump (Часть №. 1307019-81Д) и Шестигранный фланцевый болт (Часть №. Q1840820). The flange head design is standard on the Русский водяной насос FAW to distribute clamping load over the aluminum housing, preventing stress fractures around the bolt holes.

For areas requiring component stacking, а Комбинированный болт (Часть №. CQ1461025) используется. These bolts feature integrated washers that bite into the mating surface, providing resistance to vibrational loosening. В Русский водяной насос FAW приложение, maintaining torque on these bolts is vital, as a loose pump will eventually fret against the block face, ruining the sealing surface.

The assembly also includes the Small Cycle Connecting Pipe (Часть №. 1306023-53Д). This pipe connects the pump to the bypass circuit, allowing coolant to recirculate within the block during warm-up. The structural integrity of this pipe and its connections to the Русский водяной насос FAW are essential for the proper functioning of the thermostat bypass logic.

Разбивочный список компонентов

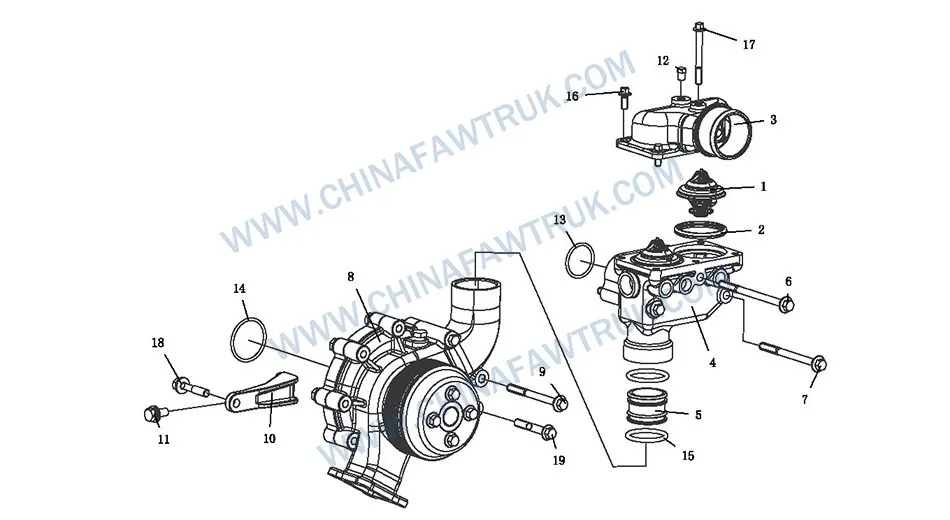

The following table is the complete, itemized breakdown of the Русский водяной насос FAW and integrated thermostat assembly. Every component listed, from the main pump body to the smallest sealing ring, is critical for the leak-free operation of the cooling system.

| Нет. |

Номер детали |

Наименование |

Кол-во |

| 1 |

1306010-81Д |

Thermostat Assembly |

2 |

| 2 |

1306011-29Д |

Thermostat Sealing Ring |

2 |

| 3 |

1306013-81Д |

Thermostat Upper Cover |

1 |

| 4 |

1306021-51Б |

Thermostat Seat |

1 |

| 5 |

1306023-53Д |

Small Cycle Connecting Pipe |

1 |

| 6 |

1306062-81Д |

Болт – For Thermostat |

1 |

| 7 |

1306063-81Д |

Болт – For Thermostat |

2 |

| 8 |

1307010-55р |

Сборка водяного насоса |

1 |

| 9 |

1307019-81Д |

Болт – For Water Pump |

2 |

| 10 |

1307046-81Д |

Water Pump Bracket |

1 |

| 11 |

CQ1461025 |

Комбинированный болт |

1 |

| 12 |

CQ61801 |

Hexagon Head Taper Screw Plug |

1 |

| 13 |

CQ7343412C |

Hydraulic Pneumatic O-Ring Rubber Seal |

2 |

| 14 |

CQ7343530C |

Hydraulic Pneumatic O-Ring Rubber Seal |

1 |

| 15 |

CQ7345462C |

Hydraulic Pneumatic O-Ring Rubber Seal |

2 |

| 16 |

Q1840820 |

Шестигранный фланцевый болт (Грубый хвостовик/Стандартный) |

5 |

| 17 |

CQ1461055 |

Комбинированный болт |

1 |

| 18 |

Q1841065 |

Шестигранный фланцевый болт (Грубый хвостовик/Стандартный) |

2 |

Diagnostic Protocols for Pump Health

Inspecting the Русский водяной насос FAW begins with the weep hole. A small amount of coolant seepage is normal during the break-in period, but continuous dripping indicates a failed internal mechanical seal. If coolant is visible at the weep hole, а Сборка водяного насоса must be replaced immediately to prevent bearing washout and seizure.

Check the Water Pump Bracket for stress cracks. Vibration from the heavy-duty diesel engine can fatigue the metal, especially if the mounting bolts have been over-torqued. A cracked bracket will lead to belt misalignment, causing the pump pulley to wobble and shred the drive belt.

Окончательно, inspect all Hydraulic Pneumatic O-Ring Rubber Seals during any disassembly. If the rubber feels hard or flattened, it has lost its sealing capability. Reusing old O-rings in the Русский водяной насос FAW system is a guaranteed recipe for leaks. Always lubricate new seals with clean coolant before installation to ensure they seat correctly without tearing.

Заключение: The Flow of Reliability

The Русский водяной насос FAW is a robust component designed to meet the extreme demands of the Russian climate. Its reinforced impeller and high-quality bearings ensure consistent coolant flow, protecting the engine from thermal stress. The integrated housing design simplifies maintenance while maximizing structural rigidity.

Для владельцев автопарков, there is no substitute for genuine parts. Aftermarket water pumps often use inferior seal materials and weaker castings that cannot survive the harsh vibration and temperature extremes of the Русский водяной насос FAW operating environment. By investing in the genuine article, you ensure that your fleet remains cool, эффективный, and operational, mile after mile.

Упаковка и логистика

Запчасти ФАВ, включая блок цилиндров в сборе, тщательно упакованы, чтобы обеспечить безопасную доставку. Каждый компонент закреплен защитными материалами для предотвращения повреждений при транспортировке.. Логистическая сеть гарантирует своевременную доставку по всему миру., поддержка эффективных операций по техническому обслуживанию. Ниже приведено изображение, иллюстрирующее стандартную упаковку запчастей для грузовиков FAW., демонстрация внимания к деталям в обращении и хранении.

Такой подход к упаковке сводит к минимуму риск коррозии или ударного повреждения., обеспечение доставки таких деталей, как блок цилиндров FAW в сборе, в идеальном состоянии.. Клиенты могут положиться на логистику FAW для обеспечения стабильного качества и надежности..